Allied Radio Knight-Kit 83 Y 140 User manual

@®

REGISTERED

TRADEMARK

OF

ALLIED

RADIO

CORP.—100

NORTH

WESTERN

AVENUE,

CHICAGO

80,

ILLINOIS

TELEPHONE

HAYMARKET

1-6800

copyrighted

1956,

by

Allied

Radio

Corp

/

printed

in

U.S.A.

20,000

OHMS/VOLT

VOM

83

Y

140

ASSEMBLY

MANUAL

HOW

TO

BUILD

THE

KNIGHT

VOM

The

improved

circuit

design

of

the

KNIGHT

VOM

assures

a

sensitive

and

accurate

test

instrument

for

the

radio-

TV

serviceman,

the

laboratory

technician,

or

the

amateur.

You

may

measure

any

AC

or

DC

voltage

found

in

radio

and

electronics

work

up

to

5000

volts.

The

input

resistance

for

DC

scales

is

20,000

ohms

per

volt.

This

enables

you

to

read

voltages

in

high

impedance

circuits

with-

out

interfering

with

the

circuit.

For

AC

voltage

measurements

it

is

5000

ohms

per

volt.

Direct

currents

may

be

meas-

ured

up

to

10

amperes.

There

are

three

resistance

ranges.

Center

scale

readings

are

at

12,

1200,

and

120,000

ohms.

All

multipliers

are

1%

precision

resistors,

which

assure

ac-

curate

measurements

for

the

life

of

the

instrument.

Check

all

of

the

parts

against

the

Parts

List

as

you

unpack

the

VOM

kit.

If

you

are

unable

to

identify

some

of

the

parts

by

sight,

locate

them

on

the

pictorial

dia-

grams.

Hardware

is

listed

in

the

last

part

of

the

Parts

List.

To

keep

our

kits

at

the

lowest

possible

price,

we

frequently

weigh

hardware,

rather

than

to

count

it

one

by

one.

Therefore,

do

not

be

concerned

if

more

nuts

and

machine

screws

for

ex~

ample,

are

supplied

than

are

specified

in

the

Parts

List.

The

only

tools

you

will

need

are:

long-

nose

pliers,

diagonal

cutters,

a

screw-

driver,

a

small

set-screw

driver,

and

a

soldering

iron.

Building

your

KNIGHT

20,000

ohms

per

volt

VOM

will

be

easier

if

you

study

all

of

the

diagrams

and

instructions

before

assembly

is

started.

The

pictorial

diagrams

show

the

actual

location

of

all

parts

and

wiring.

The

KNIGHT

VOM

will

work

best

when

all

parts

are

placed

as

shown

in

the

dia-

grams.

The

schematic

diagram

shows

how

the

parts

are

connected

electrically,

and

is

useful

in

understanding

how

the

instrument

works.

These

step-by-step

instructions

were

prepared

while

actually

building

the

KNIGHT

VOM.

They

are

the

best

and

fastest

way

of

assembling

this

unit.

May

'

we

suggest

that

you

check

off

each

step

after

you

have

completed

it.

Some

build-

ers

also

put

a

pencil

mark

on

the

wiring

views

along

the

leads

and

parts

that

they

have

just

installed.

Both

of

these

methods

are

good

and

will

assure

speedy

and

correct

wiring.

WIRING

AND

SOLDERING

The

quality

of

workmanship

in

test

equipment

will

often

determine

whether

an

instrument

will

be

an

accurate

and

re-

liable

service

tool.

While

these

wiring

and

soldering

hints

will

be

more

helpful

to

a

beginner

in

electronics,

the

more

ex-

perienced

builder

may

also

benefit

by

re-

viewing

them.

Make

good

mechanical

connections

at

joints,

clean

metal

to

clean

metal.

Loop

the

wires

around

the

switch,

other

con-

nection

terminals,

and

clamp

tight.

Cut

the

excess

lengths

of

all

end

leads

of

the

resistors

when

they

are

soldered.

When

a

solder

connection

is

made

close

to

one

of

the

precision

resistors,

hold

the

jaws

of

a

pair

of

long-nose

pliers

on

the

lead

between

the

tip

of

the

soldering

iron

and

the

resistor

to

conduct

the

heat

away

from

the

resistor.

Arrange

the

long

wire

leads

to

lay

close

to

the

panel.

USE

ONLY

ROSIN

CORE

SOLDER.

Use

the

rosin

core

solder

supplied

with

the

kit

as

KITS

WIRED

WITH

ACID

CORE

SOL-

DER

OR

ACID

FLUX

WILL

CORRODE

and

WILL

NOT

WORK

FOR

LONG.

SUCH

KITS

ARE

NOT

ELIGIBLE

FOR

REPAIR

OR

SERVICE.

The

soldering

iron

tip

must

be

well

tinned.

First,

clean

the

tip

with

steel

wool

or

a

fine

file

until

the

bright

copper

shown

in

Figure

6

and

on

the

label.

The

large

‘‘C’’

battery,

B-1,

fits

into

the

space

shown

by

the

dotted

lines

on

the

label.

The

positive

end

of

this

battery

must

be

toward

the

left.

(

)

Install

the

small

penlite

batteries,

B-2,

B-3,

B-4,

and

B-5,as

shown.

The

positive

end

of

B-2

and

B-4

must

be

toward

the

right.

The

positive

end

of

B-3

and

B-5

must

be

toward

the

left.

(_

)

Place

the

battery

retaining

strap

over

the

two

screws

which

come

through

the

battery

board.

Use

two

of

the

small

nuts

to

fasten

the

retaining

strap.

See

Figure

7.

ie

Secon

the

Function

switch,

S-1l,

on

e

panel.

The

locking

pin

of

S-1

fits

into

the

small

hole

at

the

base

of

the

meter.

Use

the

other

large

nut

to

fasten

S-1.

Connect

the

other

end

of

the

2

inch

red

lead

from

terminal

50toterminal

2

of

R-24.

Solder

this

connection.

Connect

the

other

end

of

the

4

inch

yellow

lead

from

terminal

10

of

S-1

to

the

terminal

of

Jack

D.

Solder

this

connection.

Aw

Connect

the

other

end

of

the

7

inch

violet

lead

from

terminal

41

of

S-1

to

terminal

4

of

the

battery

clip

board.

Solder

this

connection.

Connect

the

other

end

of

the

3

inch

range

lead

from

terminal

28

of

S-1

to

the

terminal

of

Jack

E.

Solder

this

connection.

Connect

the

other

end

of

the

2

inch

red

lead

from

terminal

32

of

S-1

to

the

terminal

of

Jack

C.

Solder

this

connection.

Connect

the

other

end

of

the

9

inch

white

lead

from

terminal

34

of

S-l

to

terminal

1

of

the

battery

clip

board.

Solder

this

connection.

Connect

the

other

end

of

the

6

inch

blue

lead

from

terminal

38

of

S-1

to

terminal

10

of

the

battery

clip

board.

"

Solder

this

connection.

12

DS

Connect

the

other

end

of

the

5

inch

green

lead

from

terminal

42

of

S-l

to

the

positive

(marked

with

the

plus

sign

on

the

label),

terminal

of

the

meter.

Solder

this

connection.

Dy

check

all

of

the

work.

Every

connec-

tion

should

be

strong

mechanically

and

all

should

now

be

well

soldered.

You

have

finished

wiring

your

KNIGHT

20,000

Ohms

per

Volt

VOM

kit.

Check

the

wiring

very

carefully.

A

few

extra

minutes

spent

in

checking

can

save

hours

of

trouble

shooting.

(

)

Push

the

large

knob

on

the

shaft

of

S-l.

Tighten

the

set

screw

of

the

knob

against

the

flat

on

the

shaft.

(_)

Push

the

small

knob

on

the

shaft

of

R-24.

Tighten

the

set-screw.

HOW

TO

TEST

YOUR

KNIGHT

VOM

Your

KNIGHT

VOM

is

precalibrated

by

the

use

of

R-3,

the

meter

calibrating

re-

sistor

which

has

been

matched

to

the

meter

movement

supplied

in

your

kit,

and

R-8

and

R-9,

the

two

rectifier

calibrating

resistors

which

have

been

matched

to

the

rectifier

supplied

with

your

kit.

Remove

the

1.5

volt

‘‘C’’

battery,

B-1.

It

will

be

used

to

eheck

the

voltage

ranges

of

your

VOM.

Set

the

range

switch

at

2.5

volts

DC.

Insert

the

black

test

lead

into

the

jack

marked

‘‘Com’’.

Insert

the

red

test

lead

into

the

jack

marked

‘‘V-ohm-A’’.

e

Zero

the

meter

if

the

indicator

needle

does

not

rest

directly

over

the

zero

on

ES

the

scale.

Use

a

small

screwdriver

to

turn

the

adjustment

screw,

which

is

im-

mediately

above

the

OFF

position

of

the

switch,

until

the

needle

is

in

the

correct

position.

Touch

the

probe

tip

of

the

red

test

lead

to

the

positive

end

of

the

1.5

volt

‘‘c”’

battery,

B-1.

Touch

the

probe

tip

of

the

black

test

lead

to

the

negative

end

of

B-1.

The

meter

should

read

1.5

volts.

Turn

the

range

switch

to

the

10

volt

DC

scale.

On

this

scale

the

meter

should

read

1.5

volts

also,

but

the

deflection

of

the

needle

will

be

smaller.

Turn

the

range

switch

to

the

50

volt

DC

scale.

The

meter

will

read

1.5

volts

on

this

scale,

too,

however,

the

needle

deflection

will

be

very

small.

There

will

not

be

much

deflection

if

you

check

the

250,

1000,

5000

volt

scales

with

the

‘*C’’

battery.

(

)

Install

the

‘‘C’’

battery,

B-1,

on

the

battery

clip

board

again.

(

)

Push

the

handle

mounting

studs

through

the

hole

in

each

end

of

the

handle.

Insert

the

stud

through

the

hole

in

the

meter

case

on

one

side.

Use

a

shakeproof

washer

and

one

of

the

larger

hex

nuts

to

fasten

the

handle.

Insert

the

other

stud

through

the-nole

in

the

other

side

of

the

case.

Use

the

other

shakeproof

washer

and

hex

nut

to

fasten

it.

(-)

Mount

the

meter

panel

on

the

case.

Tuck

in

all

of

the

leads.

(

)

Insert

one

of

the

3/4

inch

small

ma-

chine

screws

in

each

corner

of

the

panel.

Tighten

these

screws

into

the

tapped

holes

in

the

corners

of

the

case.

Set the

range

switch

to

the

250

volt

AC

scale.

Insert

the

probe

tips

into

the

recep-

tacles

of

a

wall

outlet.

Hold

the

insulated

Part

of

the

probe

and

donot

touch

the

tips.

The

meter

should

read

between

110

and

120

volts

depending

upon

the

line

voltage

in

your

area.

You

may

find

that

the

line

voltage

will

vary

at

different

times

of

the

day.

Set

the

range

switch

to

1000

volts

AC.

The

reading

on

the

meter

will

be

between

110

and

120

on

this

scale.

HOW

TO

CHECK

THE

OHMMETER

Insert

the

black

test

lead

into

the

jack

marked

‘‘Com’’,

common,

Insert

the

red

test

lead

into

the

jack

marked

‘‘V-ohms-A’’.

Set

the

range

switch

at

XI

and

touch

the

probe

tips

together.

The

needle

should

swing

all

the

way

over

to

zero.

Adjust

the

OHMS

ADJUST

knob

to

bring

the

needle

directly

above

the

zero

on

the

scale.

.

Set,the

range

switch

at

X100

and

touch

the

‘probe

tips

together.

Again

the

needle

‘should

swing

all

the

way

over

to

zero.

Adjust

the

OHMS

ADJUST

knob

again

so

that

the

needle

zeros

correctly.

Set

the

range

switch

at

X10K

and

touch

the

probe

tips

together.

The

needle

should

Swing

all

the

way

over

to

zero.

Adjust

the

OHMS

ADJUST

knob

until

the

needle

zeros

correctly.

13

SERVICE

HINTS

If

you

have

followed

all

the

previous

instructions

carefully

your

KNIGHT

20,000

ohms

per

volt

VOM

should

operate

properly.

If

it

does

not

perform

properly

under

the

tests

outlined,

here

are

some

helpful

hints.

If

the

DC

voltage

ranges

do

not

operate

properly,

or

are

inoperative,

check

all

connections

to

and

the

placement

of

R-19,

45K

ohm;

R-20,

150K

ohm;

R-21,

800K

ohm;

R-22,

4M;

and

R-23,

15M;resistors.

If

the

AC

voltage

ranges

operate

im-

properly,

or

are

inoperative,

check

all

connections

to

CR-1,

the

rectifier,

and

all

connections

to

and

the

placement

of

R-4,

3.75M;

R-5,

1M;

R-6,

200K;

R-7,

37.5K;

and

R-8

and

R-9

the

recti-

fier

calibrating

resistors.

If

the

ohmmeter

ranges

do

not

operate

correctly,

or

are

inoperative,

check

all

of

the

connections

to

and

the

placement

of

R-17,

100K

ohm;

R-18,

80

ohm;

and

R-19,

45K

ohm

resistors.

If

the

milliammeter

ranges

do

not

op-

erate

properly,

or

are

inoperative,

check

the

connections

to

and

the

placement

of

R-11,

25.1

ohm

wirewound

resistor;

R-12,

2.5

ohm

wirewound

resistor;

R-13,

.225

ohm

wirewound

resistor;

and

R-15,

11.0

ohm

wirewound

resistor.

Should

it

be

necessary

to

replace

R-3,

the

meter

calibrating

resistor,

please

include

with

your

order

the

four

numbers

written

on

the

tape

on

the

back

of

the

meter

movement.

This

determines

the

value

of

R-3.

In

the

unusual

case

where

it

would

be

necessary

to

replace

CR-1,

the

meter

rectifier,

or

R-8

or

R-9,

the

rectifier

calibrating

resistors,

please

order

an-

other

rectifier

and

we

will

include

the

proper

value

of

calibrating

resistors

with

i.

If

the

meter

still

does

not

function

properly,

have

someone

else

check

your

wiring,

preferably

someone

with

radio

experience.

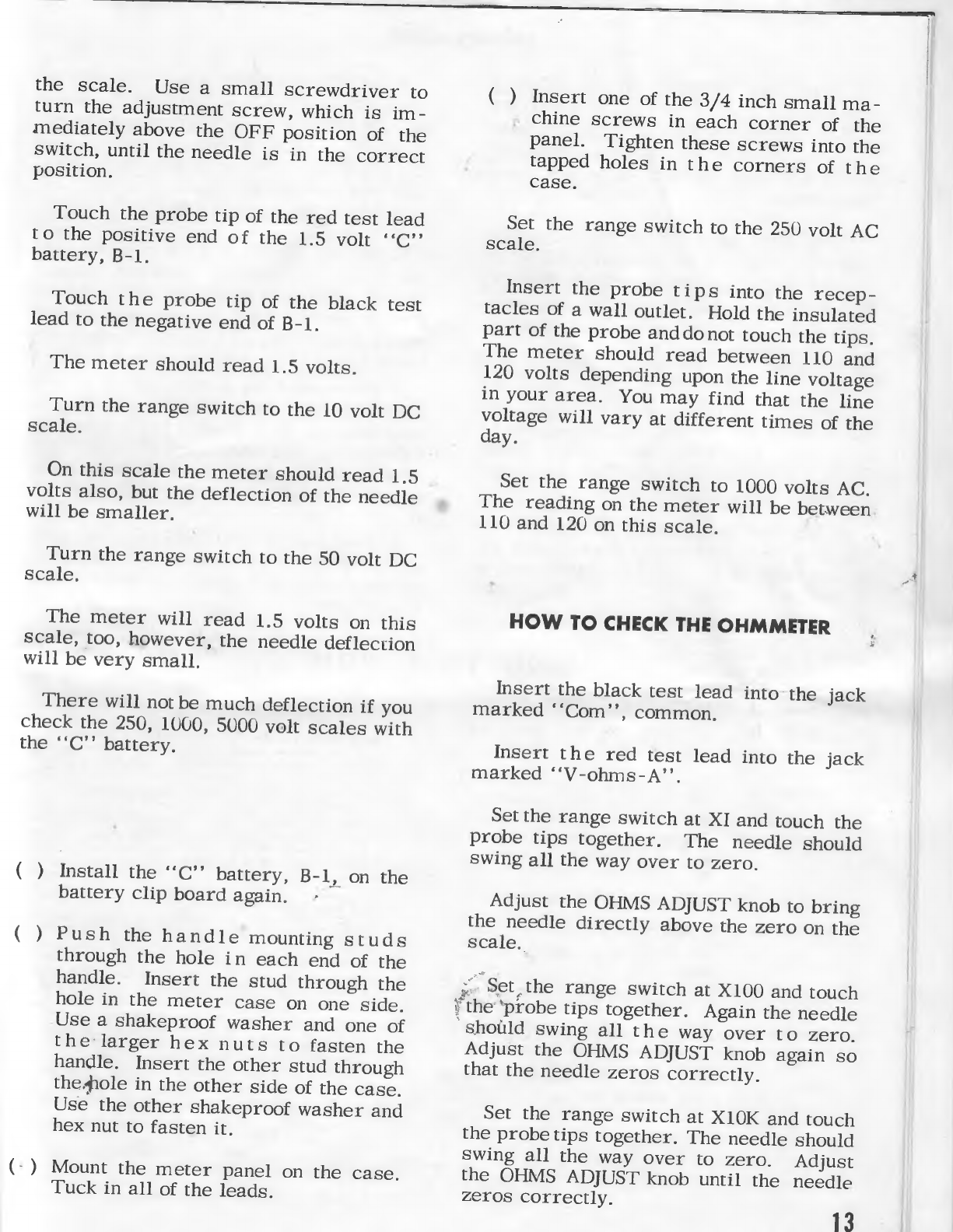

USING

YOUR

VOM

SPECIFICATIONS

0-2.5,

10,

50,

250,

1000

and

5000

volts

sensitivity

20,000

ohms

per

volt.

D-C

Voltmeter:

A-C

Voltmeter:

0-2.5,

10,

50,

250,

1000

and

5000

volts

sensitivity

5000

ohms

per

volt.

To

20

megohms

in

3

scales

with

center

scale

values

of

12,

1200

and

120,000

ohms,

respectively.

Ohmmeter:

D-C

Milliammeter:

0-0.1,

10

and

100

milliamperes.

D-C

Ammeter:

0-1,

and

10

amperes,

Accuracy:

Within

+

2%

of

full

scale

on

all

ranges.

Meter:

4-1/2

inches,

50

pa

full

scale.

Batteries:

1

flashlight,

type

C

(1”’

dia.

x

I-

15/16).

4

flashlight,

‘“‘penlite’’

type

(37/64

dia.

x

2”’).

Size:

6-3/4’

high,

5-1/4”’

wide,

3-3/4?

deep,

including

knob.

14

FUNCTIONS

Type

of

Ranges

|Measurement

0-

2.5

DIRECT

CURRENT

MA")

Type

of

Measurement

DC

VOLTS

(‘DC

Vv”)

0-

10

0-

10

ma

XI

12

ohms

mid

scale

X100

1200

ohms

mid

scale

XIOK

120K

ohms

RESIST

-

DB

Range

AC

VOLTS

-30to+

3ddb

(“AC

V"’)

0-250

|+10to

+43

db

0-

1000

}+22

to

+55db

0-

5000

|+30

to

+63

db

With

your

KNIGHT

VOM

you

can

perform

a

very

great

variety

of

measurements.

The

different

measure-

ments

are

selected

(a)

by

different

panel

jacks

into

which

the

test

leads

are

inserted

and

(b)

by

the

posi-

tion

of

the

Function

Switch.

A

number

of

scales

on

the

meter

allow

proper

readings

for

any

range

of

any

function

provided.

The

Function

Switch

has

18

posi-

tions

and

2

decks.

This

makes

it

possible

to

connect

the

different

components

of

the

instrument

so

that

d-c

and

a-c

voltages,

direct

and

alternating

currents,

and

resistances

can

be

measured.

The

meter

has

a

highly

sensitive

50-ua

moving

coil

permanent

magnet

move-

ment.

A

calibrating

resistor

(R3)

assures

the

highest

degree

of

accuracy

of

the

dial

indications.

The

meter

serves

as

the

indicator

for

all

measurements.

It

has

separate

scales

for

a-c

voltage,

d-c

voltage,

decibels,

xesistance

and

current.

Preliminary

Adjustments

Before

any

measurements

are

made,

be

sure

the

instrument

is

placed

squarely

on

a

bench

where

the

measurement

is

to

be

performed.

Always

check

that

the

meter

pointer

is

lined

up

with

the

zeros

on

the

left

hand

side.

If

the

pointer

does

not

fall

in

line

with

these

marks,

turn

the

bakelite

screw

directly

above

the

word

“‘OFF”’

either

left

or

right

until

pointer

is

positioned

correctly.

Another

reminder

before

using

the

meter

for

a

par-

ticular

type

of

measurement

is

to

make

certain

that

the

operator

understands

fully

how

to

handle

this

in-

strument,

as

well

as

its

capabilities.

With

this

in

mind,

the

following

paragraphs

are

written,

to

give

an

outline

on

how

to

use

the

KNIGHT

VOM

to

your best

advantage.

How

to

Measure

D-C

Voltoges

Coution:

Wherever

possible,

disconnect

power

from

the

equipment

under

test

before

connecting

the

meter.

In

cases

where

it

is

impossible

to

do

this,

connect

the

leads

separately

and

use

only

one_hand

at

any

one

time.

Grasp

the

test

prod

well

back

from

the

metal

tip

and

make

momentary

contact

with

the

circuit

under

test

by

letting

the

metal

tip

of

the

prod

touch

the

point

at

which

the

potential

exists.

Never

touch

any

part

of

the

equipment

under

test

with

the

other

hand.

Plug

the

black

test

lead

into

the

““COM’’

jack

and

the

red

test

lead

into

the

““V.

,

.A”’

jack.

First

touch

the

probe

end

of

the

black

(negative)

test

lead

to

the

negative

side

of

the

circuit

to

be

checked.

Then,

leaving

one

hand

free,

touch

the

red

(positive)

test

probe

to

the

positive

terminal

of

the

circuit

to

be

tested.

It

is

a

good

practice

always

to

start

with

the

highest

range

available,

as

a

protection

for

your

meter.

Then,

after

first

indication,

the

switch

should

be

reset

to

the

position

in

which

more

accurate

read-

ings

can

be

obtained.

If

possible,

make

final

readings

on

a

range

on

which

the

indication

is

in

the

right

hand

half

of

the

scale,

because

meter

accuracy

is

based

on

full

scale

value.

Turn

the

power

on

and

observe

the

meter

deflec-

tion.

(If

the

pointer

deflects

to

the

left

instead

of

to

the

right,

turn

the

power

off

and

switch

the

connections

of

the

red

and

black

test

leads

around.)

The

value

of

the

measured

voltage

can

now

be

read

from

the

appropriate

meter

scale,

taking

into

account

the

range

setting

of

the

Function

Switch.

Read

on

tne

meter

scale

whose

extreme

right-hand

Rn

marker

is

labeled

with

the

full-scale

value

indicated

by

the

Function

Switch

or

some

multiple

or

submultiple

of

it.

For

d-c

voltage

readings,

use

only

the

black

scales

marked

“*DC’’.

For

the

0-2.5

v

d-c

range

use

the

250

v

d-c

scale.

Divide

meter

scale

reading

by

10.

Each

minor

scale

division

equals

0.05

v

d-c.

For

the

0-10

v

d-c

range

use

the

10

v

d-c

scale.

Read

scale

directly.

Each

minor

scale

division

equals

-2v

d-c.

For

the

0-50

v

d-c

range

use

the

50

v

d-c

scale.

Read

scale

directly.

Each

minor

scale

division

equals

Iv

de.

For

the

0-250

v

d-c

range

use

the

250

v

d-c

scale.

Read

scale

directly.

Each

minor

division

equals

5

v

d-c.

For

the

0-1000

v

d-c

range

use

10

v

d-c

scale.

Multiply

scale

reading

by

100.

Each

minor

scale

division

equals

20

v

d-c.

For

the

0-5000

v

d-c

range

use

50

v

d-c

scale.

Multiply

reading

by

100.

Each

minor

scale

division

equals

100

v

d-c.

If

d-c

voltages

in

excess

of

1000

v

but

less

than

5000

v

are

to

be

measured,

the

red

test

lead

has

to

be

plugged

into

the

‘5000

V

DC’

jack.

If

working

with

high

potentials

of

this

order,

make

doubly

sure

that

the

Caution

paragraph

at

the

beginning

of

this

section

is

strictly

observed.

How

to

Measure

A-C

Voltages

NOTE:

Follow

same

precautions

as

under

“Caution”?

in

above

section

‘‘How

to

Measure

D-C

Voltages.

’’

Plug

the

black

test

lead

into

the

“‘COM’’

jack

and

the

red

test

lead

into

the

“‘V,

.A’’

jack.

Clip

the

probe

of

the

black

test

lead

to

one

terminal

of

the

potential

to

be

measured

and

the

probe

end

of

the

red

test

lead

should

be

touched

to

the

other

terminal

of

the

potential.

Always

start

with

the

highest

“‘AC

V’’

range

available,

as

a

protection

for

your

meter.

Then

after

obtaining

the

first

indication,

reset

the

Function

Switch

to

the

position

in

which

a

convenient

meter

reading,

preferably

in

the

upper

half

of

the

scale,

is

obtained.

Tum

the

power

on

and

observe

the

meter

deflec-

tion.

The

value

of

the

measured

voltage

can

now

be

read

from

the

appropriate

meter

scale

taking

into

account

the

range

setting

as

indicated

by

the

Function

Switch.

For

the

0-2.5

v

ac

range

use

2.5

v

a-c

scale.

Read

scale

directly.

Each

minor

scale

division

equals

0.05

v

ac.

All

other

a-c

voltage

scales

are

chosen

and

read

in

the

same

way

as

the

d-c

scales

discussed

in

the

previous

section,

except

that

the

red

“‘AC’’

scales

are

used.

If

a-c

voltages

in

excess

of

1000

v,

but

not

higher

than

5000

v

a-c

are

to

be

measured,

the

red

test

lead

has

to

be

plugged

into

the

‘5000

V

AC”

jack.

If

working

with

high

potentials

of

this

order,

be

doubly

sure

that

the

Caution

at

beginning

of

previous

section

is

strictly

observed.

19

A-C

voltage

measurements

can

be

made

at

any

frequency

from

25

cps

through

the

audio

range.

At

higher

frequencies,

shunting

capacitance

in

the

rec-

tifier

causes

readings

to

become

increasingly

low.

How

to

Measure

D-C

Resistances

Caution:

Before

making

any

resistance

meas-

ee

.

2 .

urements

in

a

circuit,

make

certain

that

the

power

is

turned

off.

It

is

also

advisable

to

discharge

any

capacitors

in

the

part

of

the

circuits

in

which

resistance

measurements

are

to

be

made.

Turn

the

Function

Switch

to

one

of

the

“‘

1

”

positions.

Plug

the

black

test

lead

into

the

‘‘COM’’

jack

and

the

red

lead

into

the

““V.

©..A’’

jack.

Con-

nect

the

prod

ends

of

these

two

test

leads

together.

Turn

the

‘‘

1.

ADJ’’

knob

until

meter

reads

full

scale

deflection,

at

which

the

pointer

lines

up

with

zero

on

the

ohms

scale.

Turn

Function

Switch

to

such

‘*

(L”’

position

that

the

meter

will

read

somewhere

in,

or

as

near

as

pos-

sible

to,

the

center

portion

of

the

scale

when

the

measurement

is

made.

Recheck

if

the

meter

deflects

full

scale

when

the

two

test

lead

probes

are

connected

together.

Connect

the

test

prods

respectively

to

the

termi-

nals

of

the

resistance

to

be

measured

and

observe

the

meter

reading.

After

any

change

of

ranges,

the

“<0.

ADJ’?

should

be

rechecked.

The

value

of

the

measured

resistance

can

be

determined

by

multiplying

the

ohms

scale

meter

reading

by

the

factor

indicated

by

the

Function

Switch

knob,

The

following

paragraph

shows

the

d-c

resistance

range

covered,

and

the

center-scale

reading

for

each

Function

Switch

setting.

If

the

Function

Switch

is

in

“‘fl

X1”

position,

the

0-1

K

ohm

range

is

covered;

center

scale

reading

is

12

ohms.

Read

scale

directly.

If

the

Function

Switch

is

in

the

“‘{L

X100”

position,

the

100

ohms

-

100

K

ohms

range

is

covered.

Center

scale

reading

is

1200

ohms.

Multiply

scale

yeading

by

100.

I£

the

Function

Switch

is

in

the

“0

X10

K’’

position,

the

10

K

-

10

Meg

range

is

covered.

Center

scale

reading

is

120

K

ohms.

Multiply

scale

reading

by

10,000.

It

always

should

be

kept

in

mind

that

in

the

measurement

of

resistance

a

current

is

made

to

flow

through

the

unknown

resistance.

Usually

this

current

is

so

smal]

that

it

can

be

neglected.

However

on

the

lowest

ohms

range

(X1)

the

halfscale

reading

is

12

ohms.

That

means

a

current

of

65

milliamperes

is

flowing

through

the

unknown

reaistor.

If

lower

re-

sistances

than

12

ohms

are

measured,

the

current

through

them

may

be

as

high

as

130

ma.

Therefore

it

is

good

practice

to

consider

the

current

flow

first

when

measuring

the

d-c

resistance

of

a

device

which

can

safely

pass

only

low

currents

without

burning

out.

For

all

other

cases

no

damage

will

result

as

long

as

the

ohmmeter

current

does

not

exceed

the

current

rating

of

the

unknown

resistance.

How

to

Measure

Direct

Current

Never

connect

the

test

leads

across

any

source

of

voltage

directly

when

the

VOM

is

used

as

a

current

meter,

otherwise

the

meter

will

be

damaged.

Instead,

always

connect

the

meter

in

series

with

the

load.

Plug

the

black

test

lead

into

the

“‘COM”’

jack

and

the

red

lead

into

the

“V.

1.

.A’’

jack.

Tum

the

Function

Switch

to

any

“MA”

or

“A’’

position

appropriate.

It

is

good

practice

to

start

with

highest

range

and

then

reset

switch

to

obtain

a

con-

venient

reading.

16

li

currents

in

the

order

of

1

to

10

amperes

are

to

be

measured,

the

red

lead

has

to

be

plugged

into

the

“10

A”?

jack.

Open

the

circuit

in

which

the

current

is

to

be

measured.

Connect

the

black

test

lead

probe

to

the

negative

side

of

the

circuit

break,

and

the

red

test

lead

probe

to

the

positive

side.

Connect

the

circuit

under

test

to

its

power

source.

The

resulting

meter

deflection

is in

a

direct

proportion

to

the

unknown

current.

To

find

the

magnitude

of

the

current,

the

meter

reading

has

to

be

multiplied

by

the

factor

indicated

by

the

Function

Switch.

The

listing

below

gives

the

different

ranges

covered,

the

scale

on

which

the

meter

reading

is

done,

and

the

multiplication

factor

of

each

current

range.

For

0-0.1

ma

range

use

the

‘‘DC

10”

scale.

Divide

meter

scale

reading

by

100.

Each

minor

scale

division

equals

0.002

ma.

For

0-10

ma

range

use

the

““DC

10”

scale.

Read

meter

scale

directly.

Each

minor

scale

division

equals

0.2

ma.

For

the

0-100

ma

range

use

the

‘DC

10”

scale.

Multiply

meter

scale

reading

by

10.

Each

minor

scale

division

equals

2

ma.

For

the

0-1

a

range

use

the

“‘DC

10’

scale.

Divide

meter

scale

reading

by

10.

Each

minor

scale

division

equals

0.02

a.

For

the

0-10

a

range

use

“‘DC

10”?

scale.

Read

scale

directly.

Each

minor

scale

division

equals

0.2

a.

If

the

meter

pointer

is

deflected

to

the

left

of

the

scale,

the

test

probes

are

connected

in

wrong

polarity.

Turn

off

the

power,

reverse

the

meter

lead

connec-

tions,

and

turn

on

the

power

again.

How

to

Use

the

VOM

as

an

Output

Meter

Sometimes

it

is

necessary

to

measure

an

a-c

voltage

which

is

superimposed

on

a

d-c

voltage.

Correct

measurement

of

the

a-c

component

in

such

a

case

is

possible

by

use

of

the

OUTPUT

circuit

of

the

VOM,

in

which

a

d-c

blocking

capacitor

is

employed

to

keep

direct

current

from

the

meter,

which

then

indicates

only

the

a-c

voltage.

To

measure

voltages

of

this

nature,

plug

the

black

test

lead

into

the

‘‘COM’’

jack

and

the

red

test

lead

into

the

“OUTPUT”

jack.

Then

proceed

as

indicated

under

‘‘How

to

Measure

A-C

Voltages’’.

Since

the

5000

v

a-c

range

would

require

a

change

in

the

red

lead

connection,

the

blocking

capacitor,

necessary

for

output

measurement

would

not

be

connected

in

the

meter

circuit,

therefore

this

a-c

range

can

not

be

used

for

output

measurements,

unless

d-c

is

kept

out

by

an

external

capacitor

or

isolating

transformer.

When

a-c

voltages

are

measured

with

the

output

meter,

the

impedance

of

the

d-c

blocking

capacitor

will

have

an

effect

on

the

accuracy

of

the

meter

reading.

The

error

which

occurs

varies

with

the

frequency

of

the

applied

voltage,

and

becomes

negli-

gible

on

the

50

v

scale

and

higher.

The

actual

voltage

will

then

be

higher

than

the

measured

value.

The

higher

the

frequency

the

smaller

this

error

will

become.

How

to

Measure

Output

Voltages

in

DB

(Decibels)

A-C

output

voltages

are

often

measured

in

units

called

decibels,

which

are

used

to

indicate

power

levels

in

amplifiers

or

general

telephone

work.

The

DB

scale

(bottom

meter

scale)

is

based

on

the

voltage

developed

across

a

500-ohm

line

when

0.006

watts

are

dissipated.

This

voltage

is

a

reference

taken

as

0

db.

Such

a

voltage

deflects

the

pointer

to

1.73

v

ac

on

the

2.5

v

a-c

range.

Therefore,

a

direct

meter

reading

in

terms

of

decibels

can

be

made

only

when

the

meter

is

connected

across

a

500-ohm

resistive

load.

Otherwise

only

relative

db

measurements

can

be

obtained.

However,

in

a

large

number

of

cases

relative

measurements

are

appropriate,

since

reference

conditions

are

defined

by

other

factors

and

only

rela-

tive

variations

are

important.

Frequency

response

to

3-db

“fall-off?

points

is

an

example.

The

following

is

the

procedure

to

obtain

a

db

meter

indication.

Plug

the

red

test

lead

into

the

“OUTPUT”

jack,

to

block

any

d-c

voltage

present

in

circuits

tested.

The

impedance

of

the

capacitor

can

be

disregarded

for

most

applications.

However,

when

no

d-c

voltage

is

present,

the

“V..0..A’’

jack

might

be

used

just

as

well.

Tbe

black

test

lead

is

plugged

into

the

“COM”?

jack.

Rotate

the

range

switch

to

a

high

‘‘AC

V’

range

and

work

down

to

one

which

is

correct

for

the

voltage

to

be

measured.

Connect

the

test

prods

to

the

point

of

the

circuit

where

the

measurement

is

to

be

made.

The

meter

pointer

will

indicate

some

reading

in

db.

If

tbe

measurement

is

made

across

a

500-ohm

impedance,

a

reading

in

absolute

db

(with

respect

to

6

mw)

is

obtained.

The

final

db

indication

is

determined

by

the

value

indicated

on

the

db

meter

scale

plus

the

addition

of

a

constant,

depending

on

the

range

setting.

The

table

at

the

lower

right

corner

of

the

meter

face

will

give

these

constants.

How

to

Measure

Alternating

Current

ge

RE

Ee

The

ac

voltage

ranges

may

also

be

used

to

measure

alternating

current

at

power

line

frequencies

by

simply

inserting

a

known

resistor

(of

low

resistance

and

sufficient

wattage

to

carry

unknown

alternating

current)

and

measuring

the

voltage

across

it.

The

formula:

I

(Amperes)

=

Sega

is

used

to

find

the

alternating

current

flowing

in

this

circuit.

How

to

Measure

Operating

Voltages_in

Electronic

Equipment

Operating

voltages

are

usually

measured

between

a

given

terminal

and

a

reference

point.

Usually

ground

(chassis)

is

this

reference

point.

Reference

voltage

data

appear

in

service

literature

in

several

different

forms.

However,

in

all

cases

the

conditions

for

these

measurements

should

be

observed,

otherwise

measurements

are

not

valid.

When

the

meter

is

connected

in

d-c

circuits,

polarity

should

always

be

observed.

The

black

lead,

connected

to

“‘COM’?

should

always

be

at

the

low

voltage

points.

Incorrect

meter

connection

will

not

produce

a

usable

meter

reading.

Since

d-c

operating

voltage

checks

will

help

to

track

down

circuit

breakdowns,

a

few

examples

of

tube

electrode

voltages,

which

actually

indicate

if

the

circuit

is

functioning

correctly,

will

be

shown.

Cathode

voltages

are

most

often

bias

voltages,

and

indicate

whether

a

tube

is

operating

over

tbe

proper

portion

of

its

characteristic.

Screen

grid

voltage

measurements

can

give

in-

dications

of

the

functioning

of

the

associated

circuits.

Very

low

voltages

at

these

points

may

indicate

a

leaky

bypass

capacitor.

Abnormally

high

voltages

might

mean

a

faulty

dropping

resistor.

Plate

voltage

measurements

can

show

an

open

plate

load

resistor

or

transformer

by

the

complete

absence

of

potential.

Low

plate

voltage

indicates

higher

conduction

than

a

high

plate

potential.

If

tbe

value

of

the

plate

load

resistor

has

a

higher

resistance

than

the

meter

impedance,

the

meter

reading

will

not

read

the

actual

existing

voltage,

but

a

value

which

is

somewhat

lower.

The

suggestions

given

under

“How

to

Measure

D-C

Voltages’’

should

be

followed

in

such

cases,

In

grid

circuits,

the

grid

leak

resistors

have

usually

a

rather

high

resistance.

The

d-c

voltages

are

also

of

low

magnitude

making

it

rather

difficult

to

use

a

fairly

high

d-c

voltage

range

to

maintain

a

high

meter

resistance.

Consequently

the

resulting

readings

are

not

a

very

reliable

indication.

In

clipper,

power

amplifier,

and

oscillator

circuits,

grid

voltage

can

be

measured

with

a

20,000

ohms

per

volt

meter,

with

a

minimum

error

occurring

since

the

grid

leak

resistance

values

are

not

very

high

and

will

not

be

affected

by

the

meter

resistance.

In

oscillators

with

grid

leak

bias,

the

grid

voltage

is

proportional

to

the

amplitude

of

the

oscillations.

Therefore

variations

of

this

voltage

when

tuning

the

oscillator

indicate

unequal

output

at

different

fre-

quencies,

D-C

voltages

in

ave

or

age

circuits

give

important

clues

of

the

operation

of

the

receiver

either

when

the

signal

is

or

is

not

received.

During

alignment

a

specified

voltage

has

to

be

applied

to

such

systems,

which

can

be

checked

by

a

VOM

connected

to

that

line.

Also

overloading,

witb

resulting

stage

blocking,

can

be

checked

by

voltage

measurement

of

the

avec

and

age

systems.

The

d-c

voltmeter

can

also

be

used

as

an

align-

ment

indicator.

For

this

purpose,

connect

the

meter

across

the

plate

load

resistor

of

the

detector

and

set

Function

Switch

until

a

deflection

of

the

meter

pointer

results.

Tben

proceed

with

the

regular

alignment

using

the

meter

as

a

peak

or

dip

indicator.

The

operation

of

a-c

circuits

in

electronic

equip-

ment

can

also

be

checked

by

tracing

the

voltages

applied

to

the

different

circuits.

The

frequency

range

of

the

VOM

permits

only

the

check

of

voltages

up

to

the

low

audio

frequencies.

For

example,

transformers

in

power

supplies

may

be

checked

by

connecting

the

meter

across

the

dif

ferent

windings

and

comparing

the

measured

voltages

to

those

given

as

references,

17

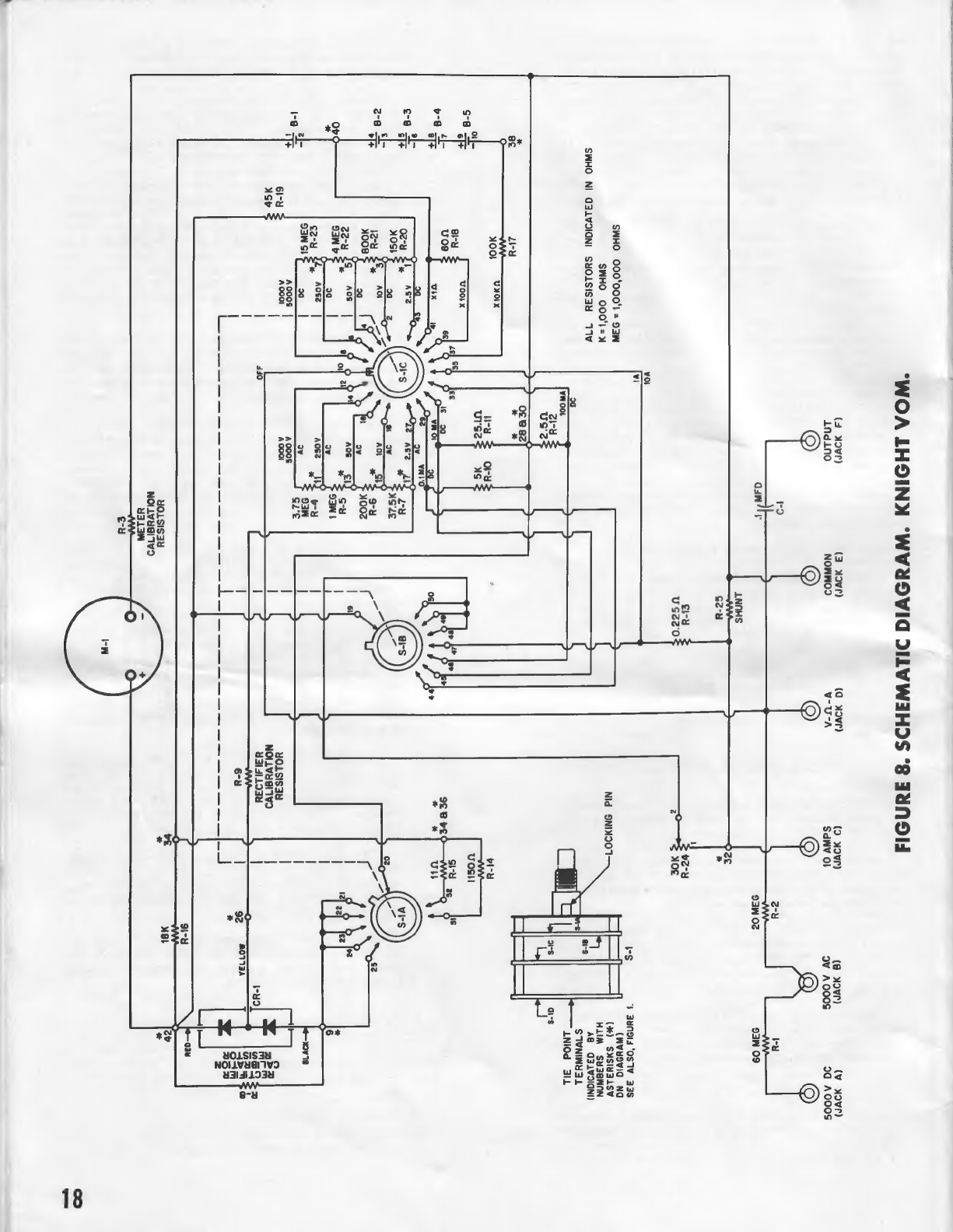

*WOA

LHOIN»

‘WVUOVIC

DILVWAHDS

°S

JUNSIA

(4

Ove)

(2

own)

(Q

yor)

(2

Ove)

(@

xOWl)

(v

Ove)

indino

NOWAWOD

V-U-A

SdWV

Ol

ov

AOO0OS

od

AO0O0OS

©

©)

©

©

2-u

iru

one's

93W

02

94W

09

ALNQHS

OZe

*

e-y

NOE

KS

‘)

aunsia

‘osTv

33S

SWHO

000‘000'!

2

93W

(WY¥SVIO

NG

ss

Nid

ONIND07

(%)

sysINais¥

SWHO

000't=

»

Him

SU3EHNN

48

Q3LVOIGNI)

STWNINM

SL

LNIOd

JIL

SWHO

NI

Q31LVSIONI

SYOLSISSY

T1V

Sb

NOLLVUSITVS

e-8

oz

e-8

7.

nie

|

ome

|

046

Oo

Yor

ov

l

of

|

Iz]

aay

ee

*

b

329

|

¢2-¥

a

aose

|

|

93

SI

od

|

re

t]+

A000S

|

|

6i-u

ro

yOLSIS3Y

|

|

|

|

Sa

a

ad

43)

411034

ee)

bt

O

aaa

rep

eres

oe

as

oo

7

292

O J

YOLSISAY

ve

¥el

NOLLVHEITVO

u31aW

e

U

€-¥

18

SYMBOL

NO

DESCRIPTION

PART

NO.

C-1

Capacitor,

paper,

.1

MFD

600V

247014

Note:

When

ordering

resistors

give

com-

plete

description

and

part

number,

R-1

Resistor,

60

megohm,

+

1%

precision

a

366005

R-2

Resistor,

20

megohm,

+

1%

precision

¥

362005

R-3

Resistor,

meter

calibrating

(packed

with

the

meter)

R-4

Resistor,

3.75

megohm,

+

1%

precision

343754

R-5

Resistor,

1

megohm,

+

1%

precision

-

341004

R-6

Resistor,

200K

ohm,

+

1%

precision

342003

R-7

Resistor,

37.5K

ohm,

+

1%

precision

ina

343752

R-8

Resistor,

rectifier

calibrating

(smaller

value)

R-9

Resistor,

rectifier

calibrating

(larger

value)

R-10

Resistor,

SK

ohm,

+

1%

precision

345001

R-11

Shunt,

wirewound

on

blue

form,

25.1

ohm,

+

1%

412517

R-12

Shunt,

wirewound

on

yellow

form,

2.5

ohm,

+

1%

410257

R-13

Shunt,

wirewound

on

red

form,

.225

ohm,

+

1%

412259

R-14

Resistor,

1150

ohm,

+

1%

precision

7

341151

R-15

Shunt,

wirewound

on

green

form,

11.0

ohm,

+

1%

410110

R-16

Resistor,

18K

ohm,

+

1%

precision

a

341802

R-17

Resistor,

100K

ohm,

+

1%

precision

a

341003

R-18

Resistor,

80

ohm,

+

1%

precision

—

340800

R-19

Resistor,

45K

ohm,

+

1%

precision

=

344502

R-20

Resistor,

150K

ohm,

+

1%

precision

—

341503

R-21

Resistor,

800K

ohm,

+

1%

precision

_

348003

R-22

Resistor,

4

megohm,

+

1%

precision

mg

344004

R-23

Resistor,

15

megohm,

+

1%

precision

351505

R-24

Potentiometer,

OHMS

ADJUST,

30K

ohm

390116

R-25

Shunt,

10

ampere,

4.3’

#14

Advance

Wire,

.025

ohm

334001

CR-1

Rectifier,

copper

oxide

621002

M-1

Meter,

50microampere

move-

ment

mountedinfront

panel

040002

SYMBOL

NO.

DESCRIPTION

PART

NO.

S-1

Switch,

FUNCTION,

2-deck

18-position

rotary

432302

B-1

Battery,

1.5

V

‘‘C’”’

450011

B-2,

3,4,5

Battery,

1.5

V

penlite

450013

Quantity

Description

Part

No.

1

ea.

Board,

battery

clip

534005

lea,

Case

701004

2

ea.

End

leads

for

R-25

470022

1

ea,

Handle

920005

6

ea.

Inserts,

jack

532006

1

ea,

Knob,

large

761301

1

ea.

Knob,

small

761001

1

ea.

Label,

paper,

showing

polarity

of

batteries

and

meter

750040

1

ea,

Manual

750041

4

ea.

Nuts,

4-36

hex

570230

2

ea.

Nuts,

10-32

hex

570540

3

ea.

Nuts,

3/8’’

hex

570840

6

ea.

Screws,

4-36

x

3/4’’

BH

560237

2

ea.

Screws,

4-36

x

3/8’’

BH

560234

24’

Solder,

rosin

core

930001

2

ea.

Spacer,

1/8”’

940002

6”

Spaghetti,

small

812001

4"

Spaghetti,

large

812003

1

ea.

Strap,

battery

retaining

470050

2

ea.

Stud,

handle

470025

1

set

Test

leads

(red

&

black)

040001

2

ea.

Washer,

lock,

#10

582500

1

ea,

Washer,

lock,

3/8"’

582700

1

ea,

Wire,

#20

bare,

9’’

length

806000

5

ea.

Wire,

red,

2’’

length

801002

3

ea.

Wire,

orange,

3’’

length

801003

1

ea.

Wire,

yellow,

4’’

length

801004

2

ea,

Wire,

green,

5’’

length

801005

lea.

Wire,

blue,

6’’

length

801006

1

ea.

Wire,

violet,

7’’

length

801007

1

ea.

Wire,

white,

9’’

length

801009

TOOLS

YOU

MAY

NEED

Stock

No.

Description

Price*

46N852

Soldering

pencil

$4.73

46N449

Long-nose

pliers

1.76

46N431

Diagonal

cutting

pliers

1.55

45N796_

6°’

screwdriver

72

43N831

Set-screwdriver

.27

*All

Prices

subject

to

change

without

notice.

19

Table of contents

Other Allied Radio Recording Equipment manuals