Allied Radio KNIGHT 96-144 User manual

PnoToFACT* FolJ"t KNIGHT

riloDEtS 96-144, 96-499

Or

o

T

I

o\

;- -.\

rrI

+*

e+

3t

ln

J

EI

o

o

==

o

E'

llt

F

UI

ri

iE

.5i

€

I

5

€

I

F'igure 1

GENERAL INFORMATICN

rhe Knight Models g6-144and g6-4gg Tape Recorders are designed to

magnetically record on a 5" or ?" reel of l/4, ' wide tape, two tracks

instead of one which doubles the playing time with no loss in frequency

response or quality. 'rhese models 96-144 and g6-4gg Recorders are

identical except f or the speed. Model 96-144 is 7-l/2,' per second

while the Model 96-4gg is g-B/4" per second.

Model 96-144 '7-t/2" per second - ?" reel - l/z hour playing time

one track, or t hour playing time - two track operation

Model 96-499 - 3-B/4" per second - ?" reel - t hour playing time one

track or, 2 hours playing time - two track operation.

These Recorders incorporate two Inputs - Radio and Microphone, two

outputs - Ext. Amplifier and Ext. speaker, Fast Forward and Fast Re-

wind. The Knight Recorders may also be used as a p.A. system.

Allied Radio C orporation

83.? West Jackson Boulevard, Chicago ?, Illinois

TOHE

YOLUME

c0l{TR0t

fhis msteriol compiled ond published by

sAtls & co., lNc., lNDlANApOllS, INDIANA

COPYRIGHT l95a . ALL RIGHTS RESERVED

DATE I - 52 $rT t58 TOTDER 6

HOWAR,D l/.

*\...-ar

*;ji

't:

*

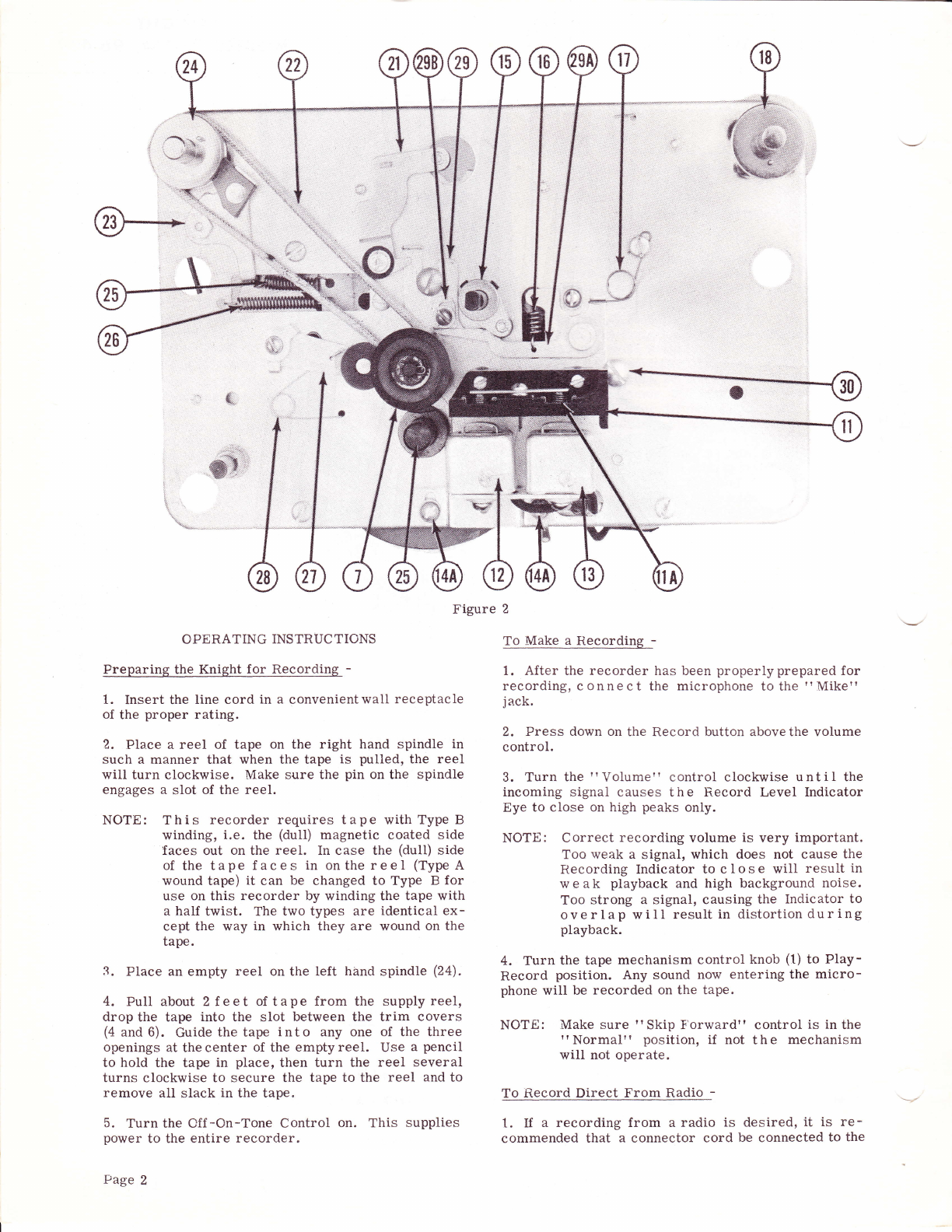

Figure 2

CPERATING INS TRUC TIONS

trreparing the Knight for Recording -

1. Insert the Iine cord in a convenientwall receptacle

of the proper rating.

2. Place a reel of tape on the right hand spindie in

such a manner that when the tape is pulled, the reel

will turn clockwise. Make sure the pin on the spindle

engages a slot of the reel.

NOTE: This recorder requires tape with Type B

winding, i.e. the (dull) magnetic coated side

faces out on the reel. In case the (dull) side

of the tape f aces in onthereel (TypeA

wound tape) it can be changed to Type E for

use on this recorder by winding the tape with

a half twist. The two types are identical ex-

cept the way in which they are wound on the

tape.

3-. Place an empty reel on the left hand spindle (2a).

4. trull about 2 f.e et of tape from the supply reel,

drop the tape into the slot between the trim covers

(4 and 6). Guide the tape into any one of the three

openings at the center of the empty reel. Use a pencil

to hold the tape in place, then turn the reei several

turns clockwise to secure the tape to the reel and to

remove all slack in the tape.

5. Turn the Cff -On-Tone Control on. This supplies

power to the entire recorder.

Page 2

To Make a Recording -

1. After the recorder has been properlyprepared for

recording, connect the microphone to the ?'Mike?'

jack.

2. Press down on the Record button above the volume

control.

3. Turn the 'r Volume " control clockwise u n t i I the

incoming signal causes the F-ecord Level Indicator

Eye to close on high peaks only.

NOTE: Correct recording volume is very important.

Too weak a signal, which does not cause the

Recording Indicator to close will result in

weak playback and high background noise.

Too strong a signal, causing the Indicator to

ove rlap will result in distortion dur ing

playback.

4. Turn the tape mechanism control knob (1) to PIay-

Record position. Any sound now entering the micro-

phone will be recorded on the tape.

NOTE: Make sure " Skip F'orward" control is in the

"Normal" position, if not the mechanism

will not operate.

To fi.ecord Direct From Radio -

t. If a recording from a radio is

commended that a connector cord desired, it is re-

be connected to the

,*t

,;:r ii

,! /"4

6il ,'j td

*\'t \i ,:"

irffi -','. Jf

\' r4ffi*.

{":

.... l

'l, l:i' :ttl%

""8 r ffi'

* *'*

T

t

I

J

fta)

3

o

E,

trt

F

UI

r2

IE

.s=

€

o

i

I

€

q.

./

-J"

uv

Figure 3

speaker voice coil of the radio, by means of alligator

clips, and the other end (using a standard phono plug)

of the cord plugged into the " Fadio" Input.

2. Better quality recording from a radio set can be

obtained by connecting to the output of the second de -

tector (usually right across the volume control of the

radio set). This kind of connection may be desirable

in some cases, because any circuit deficiencies in the

amplifier of the radio will not be included in the re-

cording.

To Record From Record Pla er-

1. Connect the output leads of the crystal pickup to

the Radio Input jack through the connecting cable.

2. If the player has a. magnetic cartridge connect to

the output of the preamplifier.

To Stop the Recorder -

The recorder may be stopped at any time by turning

the mechanism control (1) to 'r Offrt. This stops the

movement of the tape and removes the power to the

motor.

Two Track Recording -

1. The Knight is designed for two channel recordings,

therefore, after a reel of tape has been recorded a

second track may be recorded on the same reel, which

doubles the playing time with no Ioss of frequency

response or quality.

NOTE: Recordings are made on l/2 the tape width at

a time; thereby, resulting in two channel re-

cording.

2, This two channel operation is accomplished by re-

moving the reels f rom the recor{er, turning them

over, then placing the f ulI reel of tape on the Feed

Reel spindle (18) and the empty reel on the Take Up

spindle (24).

3. Thread the tape and proceed with the recording in

the same manner as previously described.

4. After this track has been recorded the first track

of recording is ready to be played without rewinding.

5. To Play the first track of recording piace the full

reel on the Feed li,eel spindle and the empty reel on

the Take Up spindle. Thread the tape making sure

the (duII) side of the tape faces the heads, then set

the control as described under "To Play a R,ecording" .

'Io Rewind The Ta

t. To rewind a portion of the tape, or an entire

channel of recording for playback, the tape must be

rewound to the starting point of the recording.

2. First make sure the recording light just above the

Tone control is out. If not, depress the record button

above the Volume control.

3. Turn the mechanism control (1) to " Rewind'r .

Page 3

tt,f

To Plav a Recordi

1. Make sure the tape is threaded properly.

2. Be sure the record light over the Tone control is

out.

3. 'Iurn the mechanism control (1) to trIay-iiecord

position.

4. Set the volume and tone controls at desired levels.

Fast f'orward -

The control marked " Skip Forward-Neutral-Normal"

on the left side of the upper control panel enables you

to skip forward at high speed to any desired section of

the tape. This control is to be used only when the tape

is moving forward in the plav position. 'Iurn the con-

trol to the lef t through the "Neutral" position and

into the "Skip Forward" position holding it there

until the desired place on the ta-pe is reached. Then

release the control by allowing it to spring back into

'rNeutral". Then, move the control backinto

tt Normaltt.

To Plav a Recording Through

an External Amplifier -

1.. Frepare a shielded c able with the proper plugs,

connecting one end of the cable to the Amplifier Cut-

put of the recorder and the othe4 end to the " phono"

.t-age 4

ti

;.ii; iii

ry-:::

input of any good radio set, or high-fidelity record

player amplifier.

To PIav a Recording Through

an External Speaker -

1. Any external FM speaker having a3.2 ohm voice

coil may be plugged into the External Speaker jack

output. vVhen an external speaker is plugged in, the

internal speaker is automatically disconnected.

Using the Knight Recorder as a tr.A. Svstem -

1. Plug the microphone into the Radio jack.

2. Be sure the recording light above the tone control

is out.

3. Keep the microphone as far as possible from the

unit to avoid feed back or 'rhowl'r and adjust the tone

and volume controls to your requirements.

ADJUSTMENTS

Motor Power Switch - (See I'igure 4) -

1. The Off -On-Tone control when turned on supplies

power to t h e entire mechanism, however, the motor

will not run until the mechanism control knob (1) is

turned to either Record-PIay or Rewind trosition,

causing the switch (51) to make contact. Therefore

the switch contacts should be open when the mechan-

ism is in " Stop" position.

;i::::-T,i:

if\

&d

l"

I

Figure 4

To adjust the motor switch, turn the mechanism con-

trol to the " Stop" position. Loosen the two screws

(54A) and adjust the srvitch to the center of the bake-

lite pin on the motor swing plate (51). Continue to

move the switch until there is approximately 1/16'r

gap between the contacts. Tighten the screws (54A).

The Forward Stop Lug - (See Figure 4) -

The forward Stop lug (52) should be set so the motor

swing plate assembly (51) comes to a rest position

against it as soon as the motor pulley (5?) makes firm

contact with the flywheel (40). Excessive pressure

against the flywheelwillprevent the motorfrom start-

ing when the control lever is turned to the " Play-

Recordir position. Insufficient pressure will result

in slippage causing rr i!'owtt. The best setting is to

adjust the forward Stop lug (52) l/16,, from the edge

of the swing plate (51) at the point when the drive

roller begins to touch the flywheel.

There is no motor plate stop adjustment in the ttRe-

wind" position; however, the rewind drive pulley (3?)

is located in a hanger whose position is adjusted by

bending the Stop lug (3?A), see Figure 3, against the

swing plate pushing in a manner that will allow a

clearance between the drive roller (5?) and the re-

wind pulley (3?) in the "Stop" position. This will

also allow the drive roller to engage the drive pulley

in the'rRewind" position. In this position, the re-

wind drive pulley hanger lug (3?A) is moved away

from the stop. The rewind drive pulley (3?) is firmly

held against the motor drive pulley (5?) by the torsion

spring (39) that needs no adjustment.

Pressure Lever and Arm Adjusting Plate -

Set the pressure lever (15), see Figure 2, so that it

is perpendicular to the pressure arm (29A) when the

control knobis in the Record-Playback position. Also

adjust the arm adjusting plate (298) so it will clear

the pressure arm (29A) bV l/64,, ,yhen in this

position.

Detent Lever (38) - (See Exploded View) -

The roller of the detent lever (38) should be adjusted

so that it will engage the detent lever (16) at point X,

as shown in the exploded view, when the controt is in

the " Off" position.

Motor Transfer Lever (41) -

'f he motor transfer lever (41) shoul.d be adjusted

when the control is in the t'Off,' position. To adjust

the transfer lever (41) loosen its set screws and move

the motor plate (51) until the motor drive pulley (5?)

is midway between the rewind drive pulley (37) and

the flywheel (40), then tighten the scrervs.

Head Fressure -

The head pressure is adjusted by means of the two

screws (14A) in the slotted holes in the head bracket

(14). See Figure 2. To make the adjustment, turn the

control knob (1) to'rRecord-Playtr position. Loosen

the screws (14A) then adjust the head into the tape

guide block {11) until the pressure pads (11A) show a

movement of slightly less than l/32,, on the reverse

side of the tape guide (11).

-

Head Alignment -

The lateral movement of each head is done by moving

the heads in the required direction by means of the

screws in the slotted holes that hold the heads to the

head bracket (14). The position should be such that

there is no hanging up of the tape pressure guide when

the control lever is turned to the " Off" position.

Make sure after the heads are adjusted that they are

parallel with the tape as it is pulled past the heads.

TROUBLES

Irregular Speed'rWowrt -

1. Felt pressure pads (11A) in tape guide assembly

(1 1) worn.

(a) Replace with new pads.

2. Oilor greaseon drive roller (5?), flywheel assem-

bly (40), or pressure roller (?).

(a) Clean with alcohol.

3. Head pressure too great (see adjustment on

I'Head Pressurer'). Be careful not to disturbthe

head alignment.

4. Check pressure roller lever (1b) to see if it is

perpendicular to the pressure arm (2gA). When in the

" Record-Flay'' position. See Adjustments on 'r pre-

ssure Lever and Arm Adjusting plate".

5. Drive roller (5?) or pressure roller (?) eccentric.

Allow mechanism to run for 20 minutes. ff after this

time the rollers are still eccentric, replace with new

rollers.

6. Motor shaft binding. Motor shaft should turn free-

ly when the control knob is in the " Off[ position. If

necessary, realign bearings by tapping motor lighily

with a wooden mallet.

?. Detent spring (26) not properly connected. See

Figure 2. If spring (26) is not connected, the detent

slide (36) will not be held against the detent lever (38)

resulting in the motor drive pulley (5?) not being held

in firm contact with the capstan.

Motor Runs but Mechanism Will Not Operate -

1. Motor transfer lever (41) not adjusted properly.

See Adjustments on " Motor Transfer Lever", and

" The Forward Stop Lug".

2. Drive roller (57) defective.

3. Fast f'orward control in 'r Neutralt' position.

(a) Turn contr.ol to tr Normalr' .

Mechanism Runs Forward But Will Not Rewind -

t. Checkdrive belt (35) for treing broken or loose.

Replace.

2. Motor transfer lever (41) not adjusted properly.

See adjustment on " Motor Transfer Lever (41)" .

Mechanism Rewinds But WiIl Not Run Forward -

1. Forward stop lug (52) out of adjustment. See Ad-

justment on rr Forward Stop Lug".

=o

(,

|lt

F

ta

s2

i0

.Ai

€

T

I

€

€

Page 5

This manual suits for next models

1

Other Allied Radio Recording Equipment manuals