PAGE 9 ALMAC s.r.l.

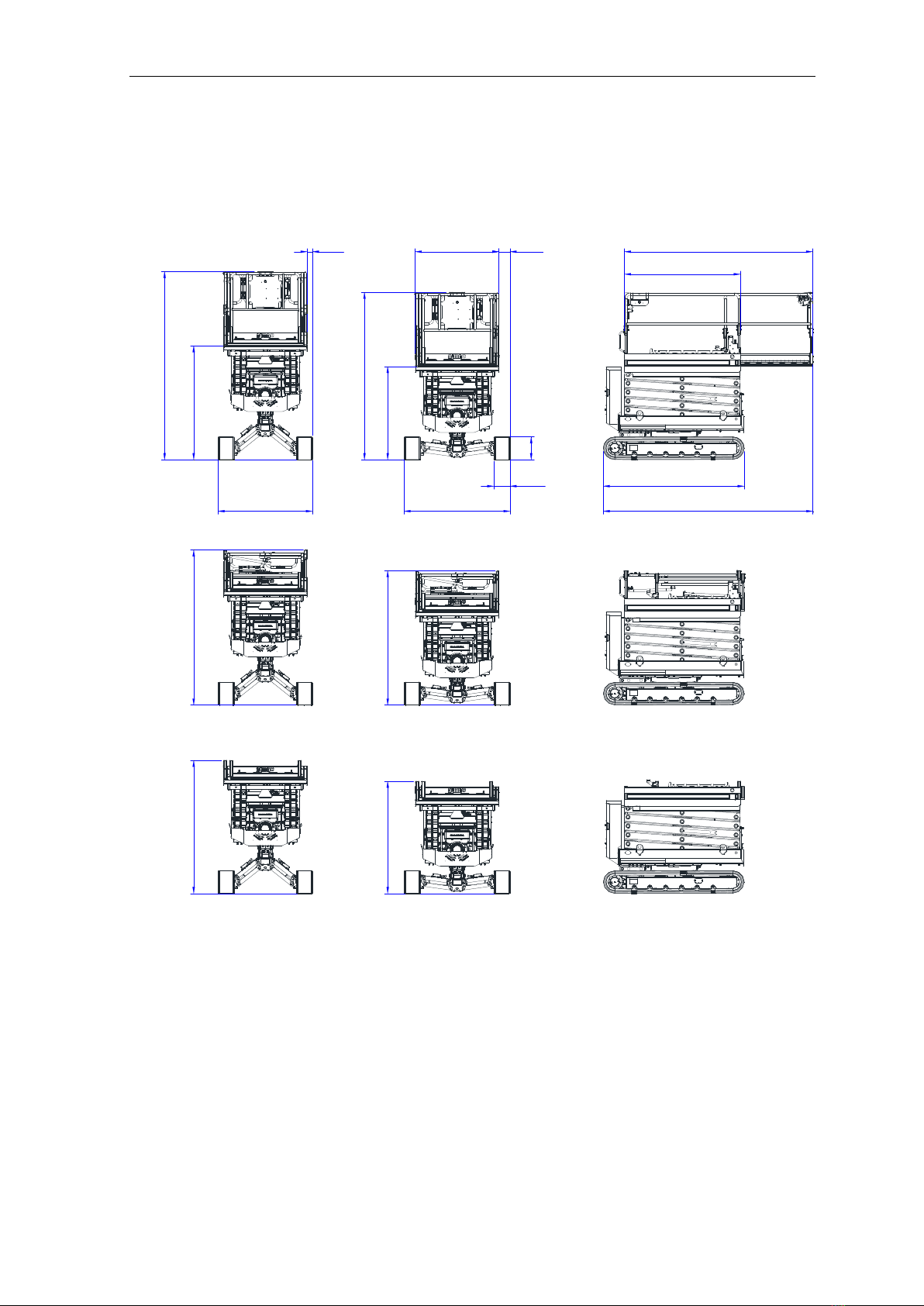

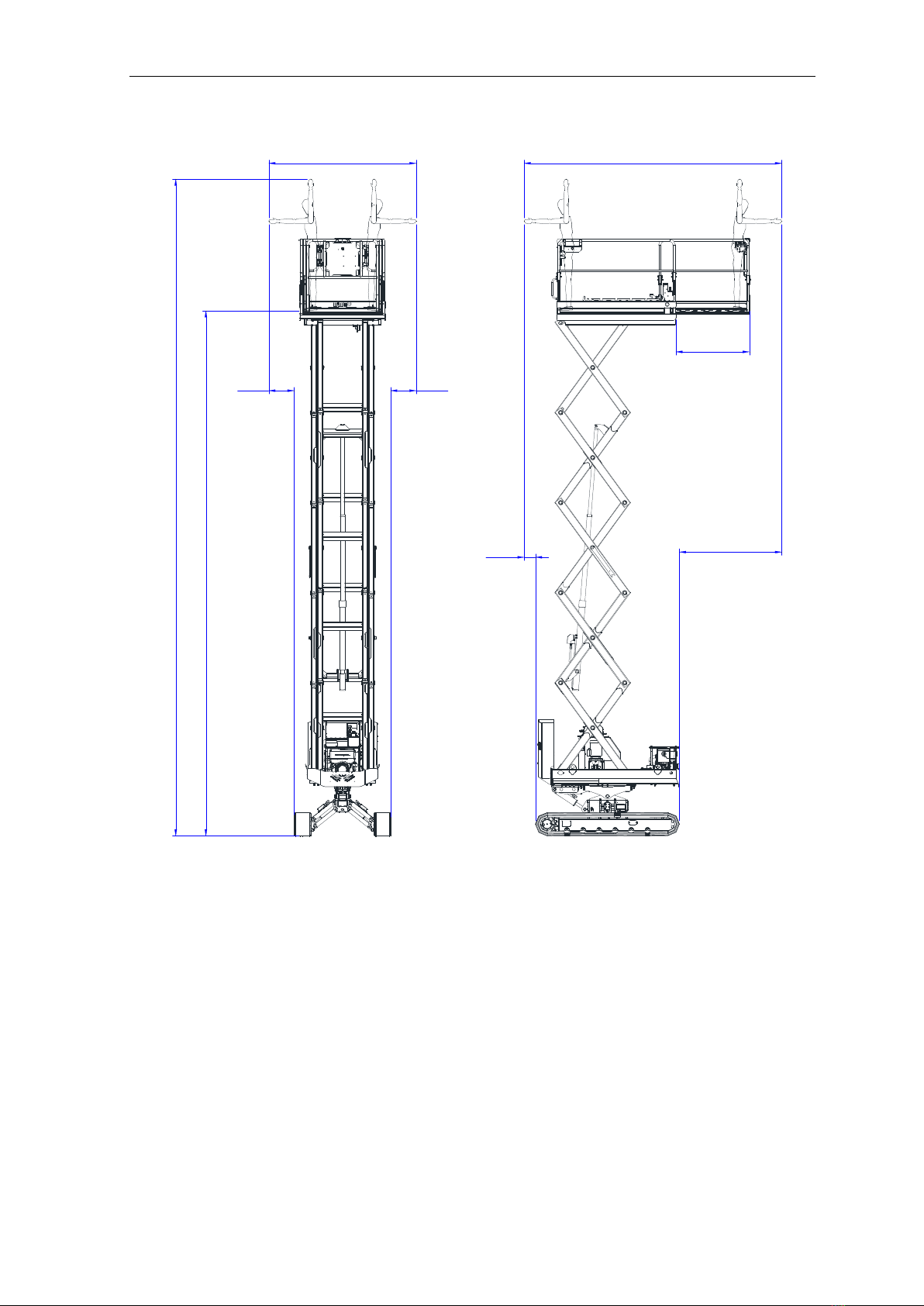

Useful work distance in length H3 mm 170

Useful work distance in length H4 mm 1540

Extension of work platform L1 mt 1.12

Technical data

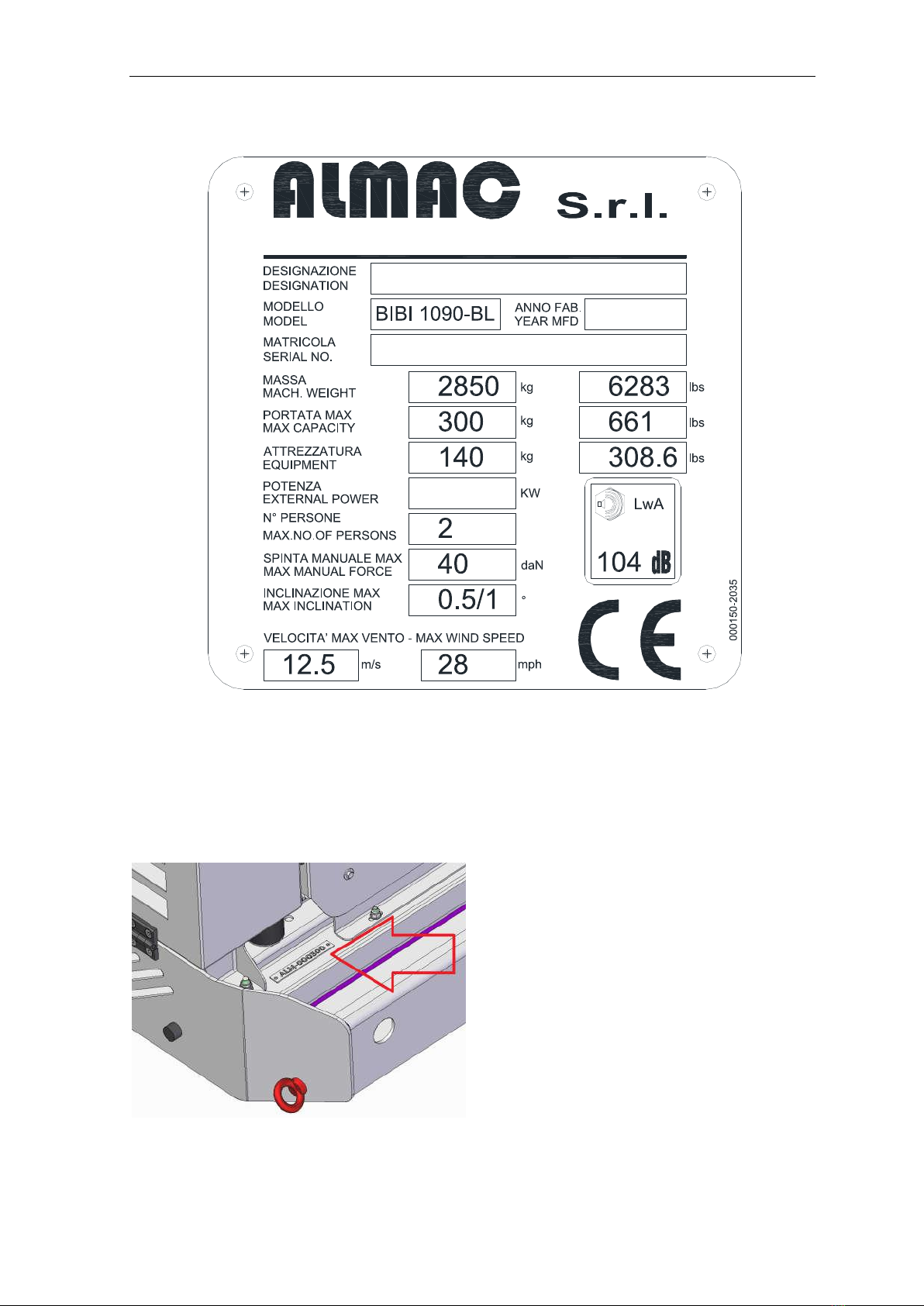

Capacity of work platform kg 300

Number of operators on work platform 2

Lifting time (with 300Kg on the platform) s 45

Lowering time s 40

Hydraulic side‐shift pressure bar 210

Hydraulic lifting pressure Bar 160

Oil tank capacity l 50

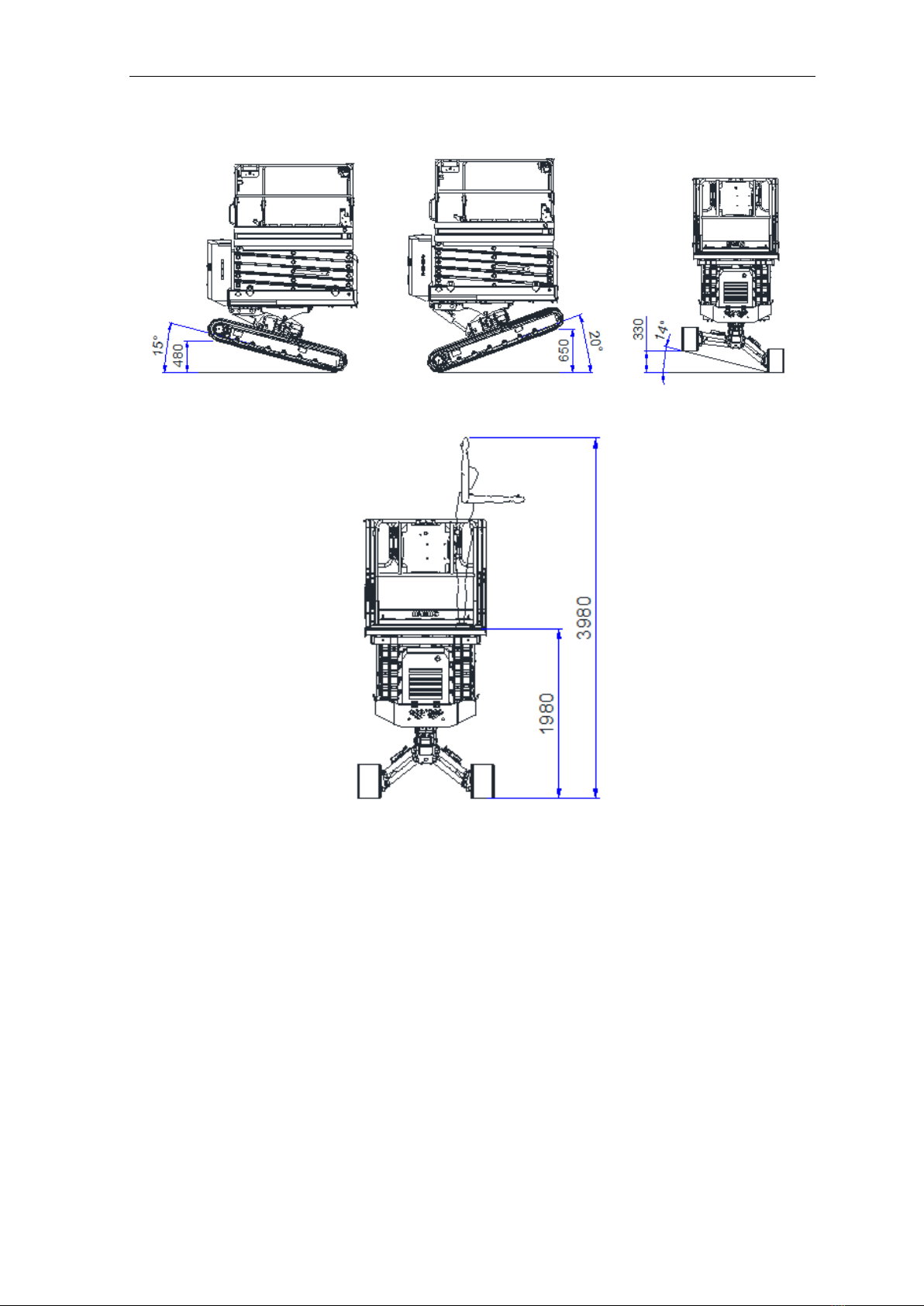

Climb angle ° 25

Maximum side slope of the terrain ° 14

Maximum longitudinal slope of the terrain ° 20 / 15

Maximum travelling speed km/h 2.4

Maximum speed with platform lifted km/h 0.4

Overall weight kg 2850

Max wind force m/s 12.5

Starter battery voltage and capacity V/Ah 12/50

Weight of starter battery kg 15

Sound power LwA dBA 104

Sound level at operator position Lp (indoor industrial environment) dBA 84.5 ± 2.6

Sound level at operator position Lp (outdoor environment on

asphalt) dBA 79.5 ± 2.6

Max peak level Lp peak dBC 106.0

Vibrations transmitted to hand / arm system (operator hand

rest) m/s2 < 2.5

Whole‐body vibration (platform‐measured on flat terrain) m/s2 0.52 ± 0.10 *

Vibrations transmitted to hand / arm system (operator hand

rest) m/s2 0.59 ± 0.12 **

* values referred to raised platform (operating height)

*** values referred to platform at the transport height limit