PAGE 4

5.1.3 Push-button panel on the platform..................................................................39

5.1.3.1 "Dead man" system. ..................................................................................................... 40

5.1.3.1.1 Enabling commands by means of the ON button. ............................................................... 40

5.1.3.1.2 Enabling commands by foot pedal (OPTIONAL).................................................................. 40

5.1.3.2 Traction and steering controls......................................................................................... 41

5.1.3.2.1 Traction speed selector switch. ................................................................................... 42

5.1.3.2.2 Steering while moving............................................................................................... 43

5.1.3.2.3 Steering with single track control ................................................................................. 43

5.1.3.2.4 Countersteering. ..................................................................................................... 43

5.1.3.2.5 Traction and steering control with DYNAMIC LEVELLING and PROACTIVE LEVELLING functions. ......... 43

5.1.3.3 Manual control of turret levelling..................................................................................... 44

5.1.3.4 Platform handling (ascents, descents, rotations)................................................................... 45

5.1.3.4.1 Platform load selection. ............................................................................................ 45

5.1.3.4.2 Platform movement controls with PROACTIVE LEVELLING function. ......................................... 45

5.1.3.4.3 Ascent / Descent of the main boom............................................................................... 46

5.1.3.4.4 Rotation of the turret. .............................................................................................. 46

5.1.3.4.5 Extension / retraction of the telescopic boom. ................................................................. 46

5.1.3.4.6 Jib up/down. ......................................................................................................... 47

5.1.3.4.7 Rotation of the platform............................................................................................ 47

5.1.3.4.8 Manual adjustment of platform levelling......................................................................... 47

5.1.3.4.9 HOME button (AUTOSTOWING)..................................................................................... 47

5.1.3.5 Other functions and devices of the control panel. ................................................................. 48

5.1.3.5.1 Emergency stop. ..................................................................................................... 48

5.1.3.5.2 HORN button.......................................................................................................... 48

5.1.3.5.3 MODE button.......................................................................................................... 48

5.1.3.5.4 LIGHTS button........................................................................................................ 48

5.1.3.5.5 USB sockets and compartments for mobile phones. ............................................................ 48

5.1.3.5.6 Warning lights. ....................................................................................................... 49

5.1.4 Ultrasonic anti-crushing and anti-collision kits (OPTIONAL). ....................................52

5.1.4.1 Operator anti-crushing kit (OPTIONAL)............................................................................... 52

5.1.4.2 Platform anti-collision kit (OPTIONAL). .............................................................................. 53

5.1.5 "AES" anti-entrapment operator kit..................................................................53

5.1.6 Pot-hole and anti-collision turret kit (OPTIONAL).................................................54

5.1.6.1 Pot-hole kit (OPTIONAL)................................................................................................ 55

5.1.6.2 Turret anti-collision kit................................................................................................. 55

5.2 CONTROL STATION ON THE GROUND. ..........................................................................57

5.2.1 Main key switch / control station selector. ........................................................58

5.2.2 Command enable button "ON" and command enabled green indicator light. .................58

5.2.3 Emergency stop button. ...............................................................................58

5.2.4 Emergency Override Button with leaded protection..............................................59

5.2.5 Warning light............................................................................................59

5.2.6 “MODE” button..........................................................................................59

5.2.7 TURRET ROTATION/LEVELING buttons...............................................................60

5.2.8 TELESCOPIC EXTENSION/RETRACTION buttons. ....................................................60

5.2.9 BOOM UP/DOWN /TURRET LEVELLING buttons.....................................................60

5.2.10 JIB UP/DOWN buttons...............................................................................61

5.2.11 PLATFORM ROTATION buttons. ....................................................................61

5.2.12 PLATFORM LEVELLING buttons.....................................................................61

5.2.13 Circular display. .....................................................................................62

5.2.13.1 Main error messages..................................................................................................... 62

5.2.14 BATTERY CHARGER indicator light................................................................66

5.2.15 Movement and alarm buzzer.......................................................................66

5.2.16 Ground control station light. ......................................................................66

5.2.17 Programming and diagnostic connector. .........................................................66

5.3 ACCESS TO THE PLATFORM.....................................................................................67

5.4 STARTING THE MACHINE. ......................................................................................68

5.5 STOPPING THE MACHINE. ......................................................................................69

5.5.1 Normal shutdown. ......................................................................................69

5.5.2 Emergency stop. ........................................................................................69

5.6 END OF WORK. ................................................................................................69

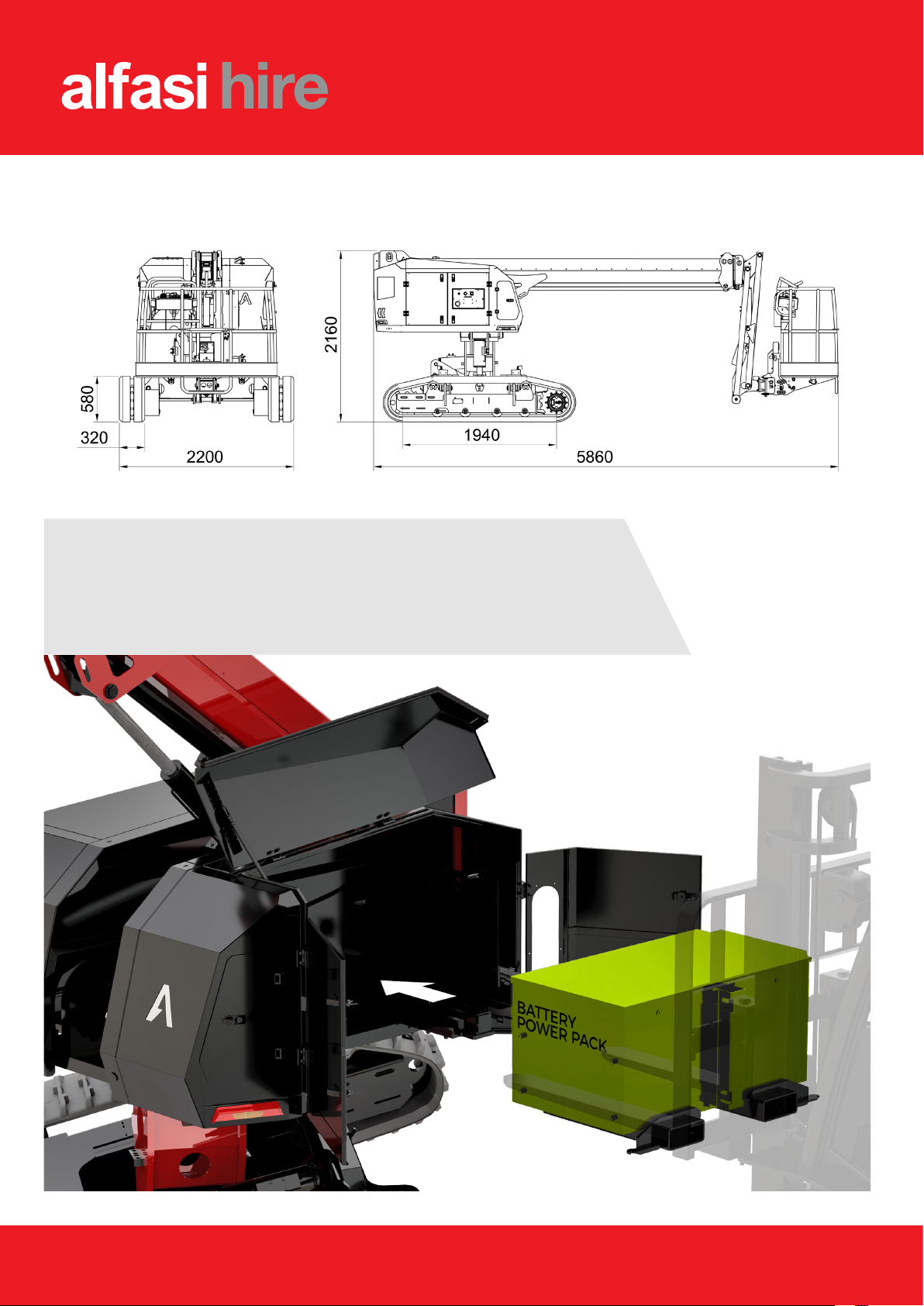

5.7 QUICK REPLACEMENT OF THE BATTERY PACK. .................................................................70

6LOADING AND TRANSPORT. .................................................................................. 71