ALMECO nv Air and water technologies

Royennestraat 51, B-7700 Moeskroen

8

EP10A compact blower

4. INSTALLATION/ OPERATION INSTRUCTIONS

a. General Safety Procedures

• Ensure all safety instructions are fully understood by the personnel undertaking the work and that those personnel

are familiar with any emergency apparatus.

• Only qualied electrical and competent mechanical personnel should be used for installation and maintenance

procedures for the EP10A/EP10AH units.

• Before any installation or maintenance work is carried out, ensure all electrical connections are disconnected from

the motor starter, fuse box, or circuit breaker and check that the power cannot be switched on.

• IEE and other relevant regulations should be observed when installing the unit.

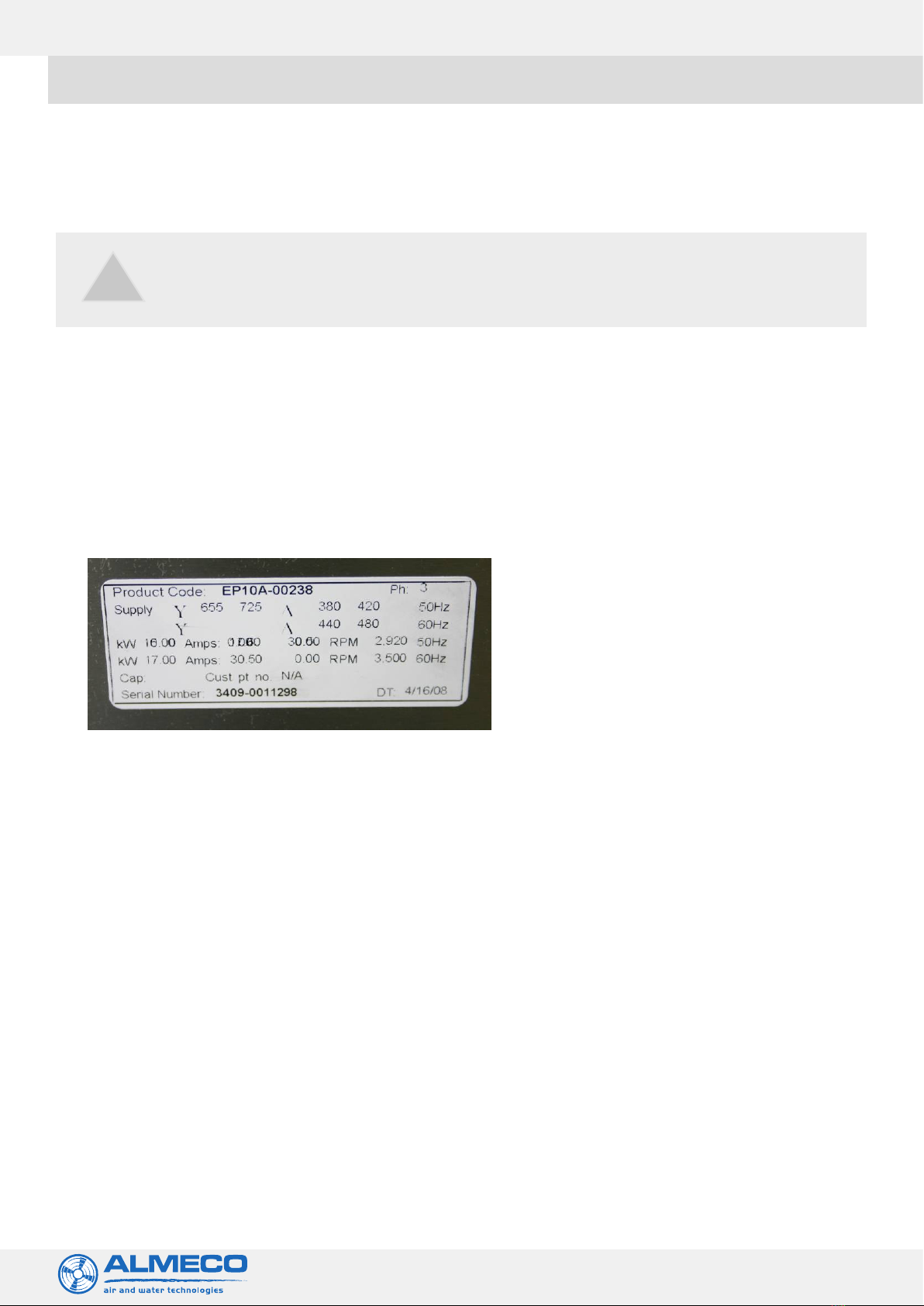

• For correct power supply requirements; please refer to the motor nameplate.

When operating this unit, please ensure good safety practices are followed. For example:

1. Ensure that the belt guard is tted.

2. The unit is not operating independently of the system without securely blanking o the outlet or inlet.

3. All tools, clothing and hands should be kept away from rotating or moving parts.

4. Ensure adequate eye, ear and foot protection is worn.

5. Lifting equipment is used to move the blower into position. When lifting please ensure that the blower is secure and

do not use the blower’s inlet spigot as a lifting point.

b. Mounting

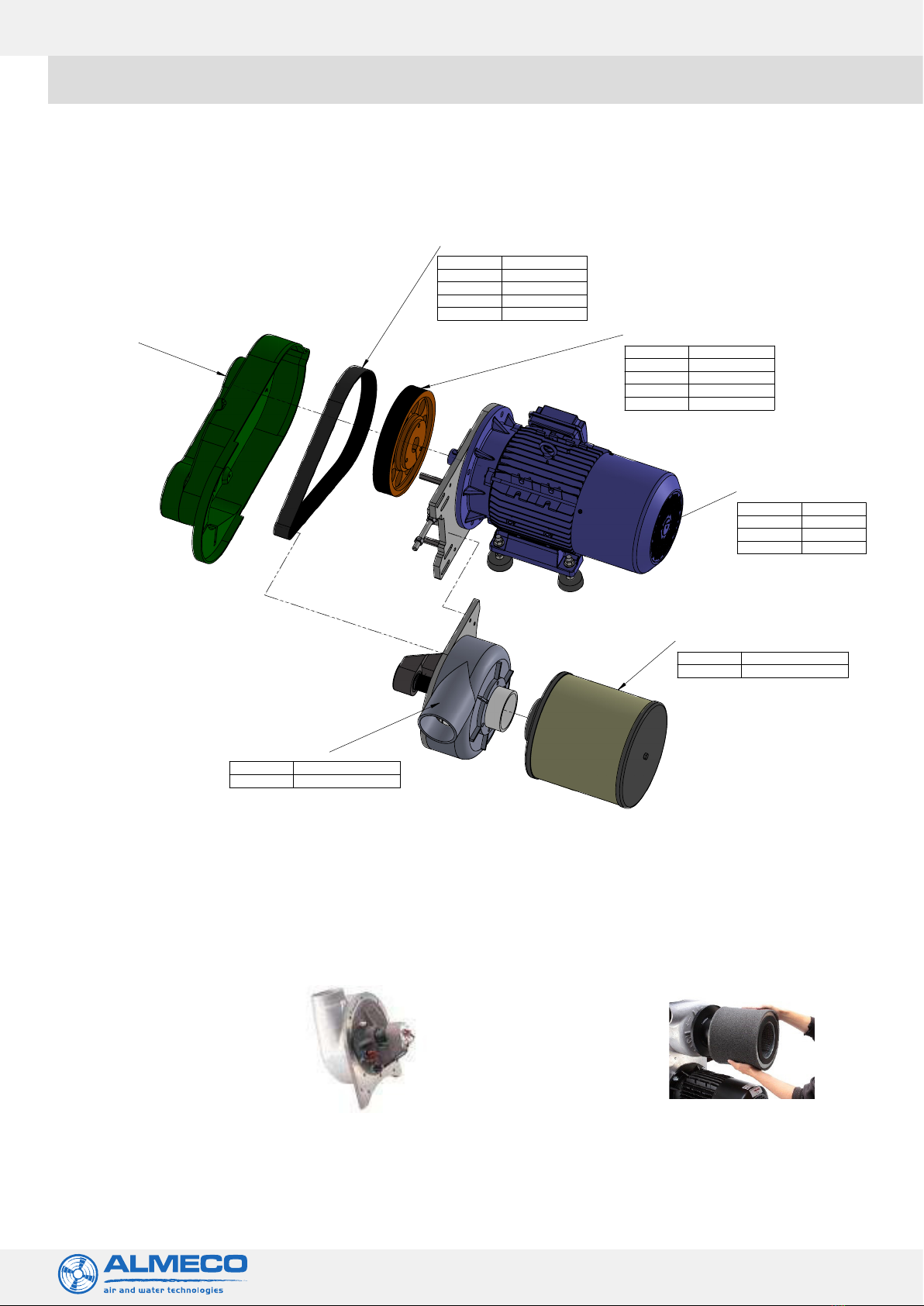

Units are normally supplied free standing from the motor mounting feet. The EP10A/EP10AH blower head is belt driven

and normally mounted from the large ange of a standard metric motor.

NEMA frame motors can be used with the blower and a special motor mounting plate is provided to suit the large ‘C face’

conguration.

NOTE: Allow room for bracket movement during belt replacement. Very low vibration levels of these units allow them

to be bolted to any type of foundation or framework without signicant eect. Vibration isolation mounts are

recommended if other motor driven equipment is to be mounted to the same structure.

c. Location

The unit assembly must be suitably located to allow access for drive belt and lter replacement. Ambient temperature

conditions should range from -10ºC to + 50ºC (14ºF to 122ºF) and adequate ventilation provided for the motor. In factory

locations subject to high-pressure water or caustic wash-down cycles, protect or relocate the blower to prevent damage.

If the unit has been supplied with an acoustic enclosure, an internal enclosure temperature of + 50ºC (122ºF) must not be

exceeded.

d. Blower connections

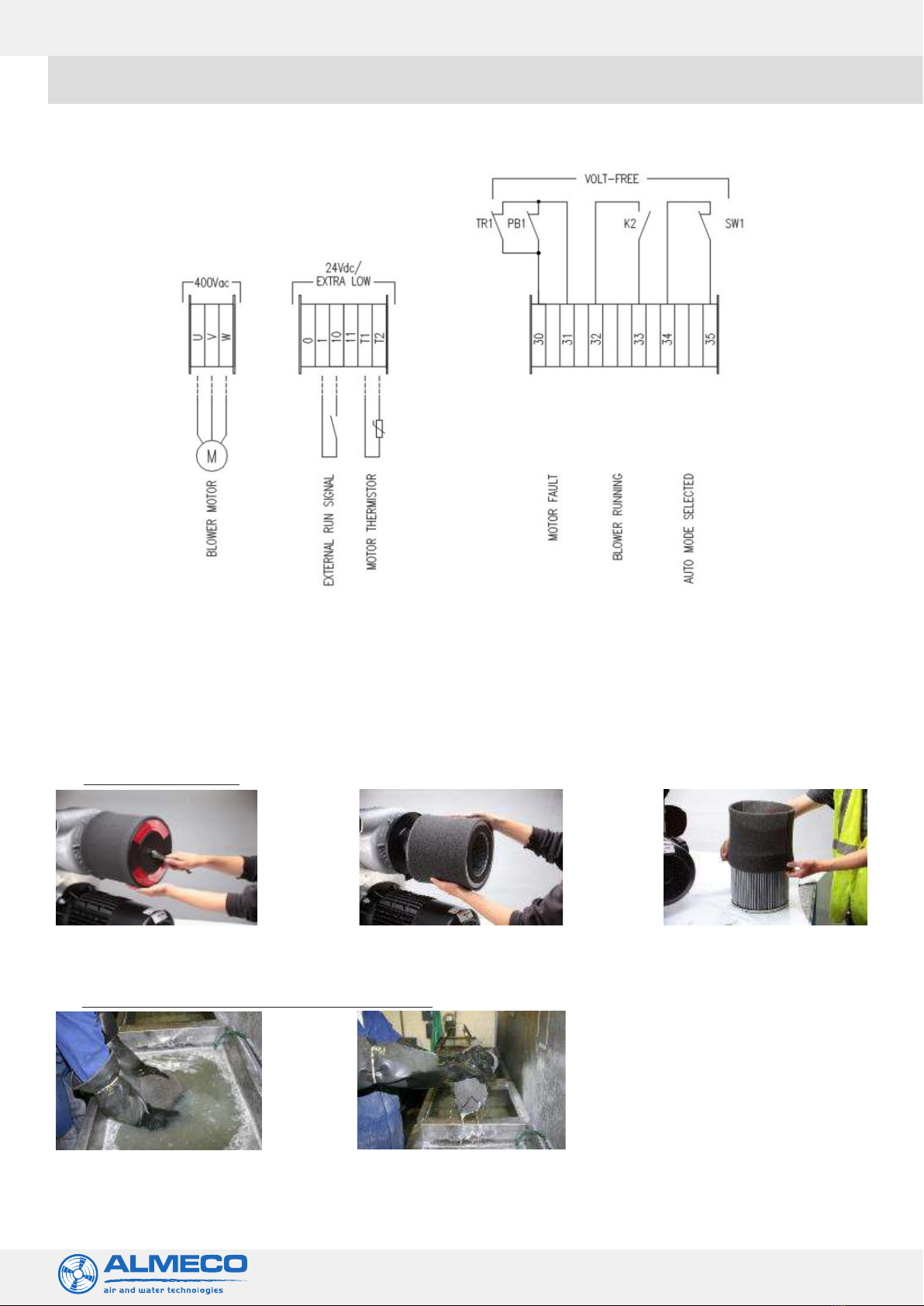

The unit is supplied with an inlet lter and discharge connection, suitable for attaching exible hose. Spigots are

Ø100mm. It is recommended that the unit discharge be coupled to system piping via a short length of flexible hose and

directed away from personnel and silenced to reduce noise levels to within occupational safety standards.

Flexible hose can introduce a high-pressure drop and lengths should therefore be kept to a minimum. The inlet filter

must not be removed, re-circulating systems are not recommended and any deviation from standard use as a blower

must be approved by Almeco. Recommended inlet air temperature is less than 50°C/122°F. The blower is designed to give

a continuous, stable supply of pressurised air and should not be subjected to frequent or large changes in back-pressure

from shut-off or diverted valves other than advised by Almeco. The blower should not be operated until it has been fully

connected to the complete system it will be operating.