Page Issue A

Chapter - Engine1:2

CN101 - Maintenance

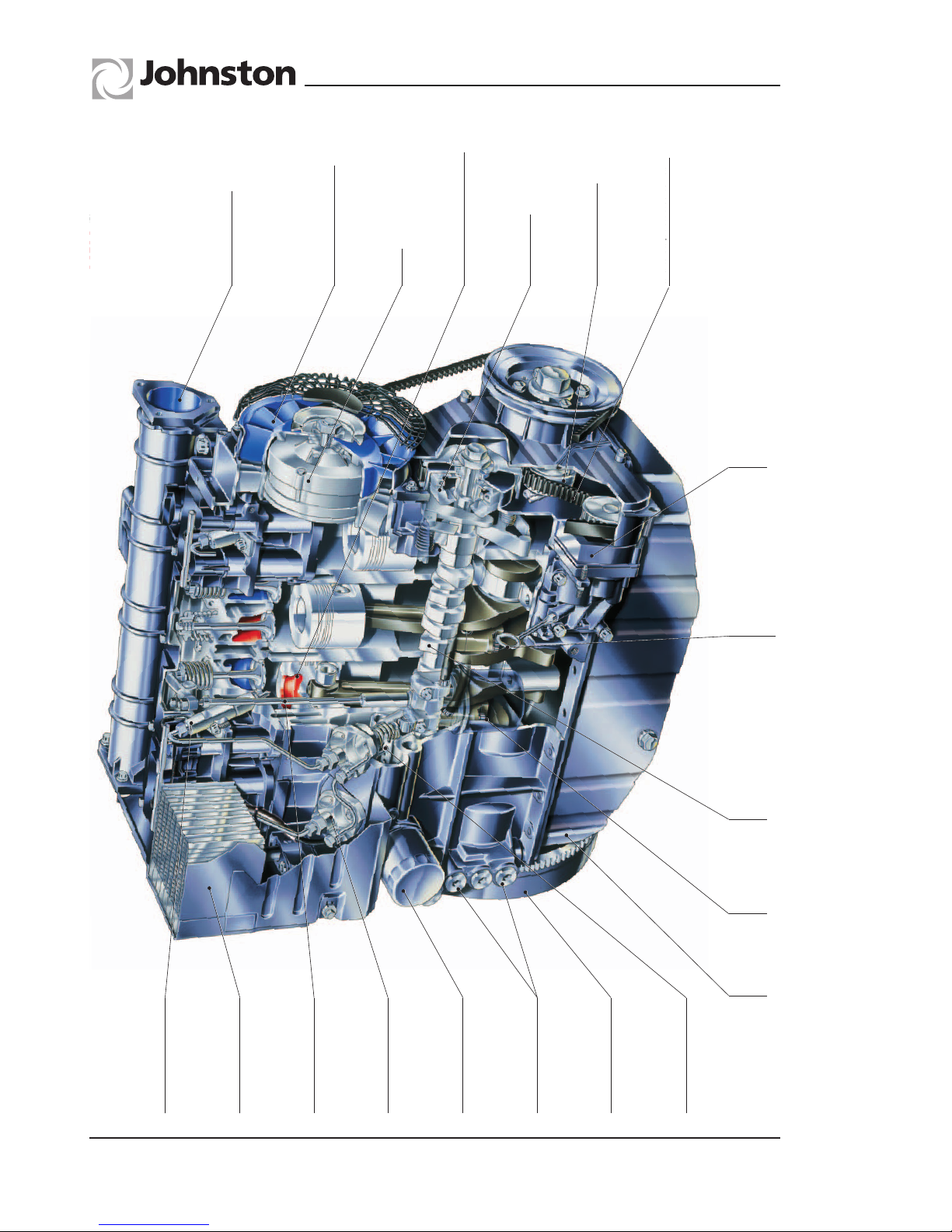

Einspritzventil

Injector

Injecteur

Inyector

Ventil-Stößelstange

Valve push rod

Tige de culbuteur

Varilla de empuje

Einzel-Einspritzpumpe

Single injection pump

Pompe d'injection individuelle

Bomba individual de inyección

Schmieröl-Filter

Oil lter

Filtre à huile de graissage

Filtro de aceite lubricante

Heizungsanschlüsse

Cab heater connections

Prise de chauage

Connexiones de calefacción

Regelstange

Control rod

Crémaillère

Barra cremallera

Schwungrad

Flywheel

Volant

Volante

Schmierkühler

Lube oil coooler

Radiateur d'huile de graissage

Refrigerador de aceite lubricante

Ölwanne

Oil pan

Carter d'huile

Cárter de aceite

Kraftsto-Filter

Fuel lter

Filtre à combustible

Filtro de combustible

Schmieöl-Peilstab

Oil dipstick

Jauge d'huile

Varilla medidora del nivel de aceite lubricante

Nockenwelle mit Einspritzpumpennocke

Camshaft with cams for injection pump

Arbre à cames avec cames de pompes d'injection

Arbol de levas con levas para bombas de inyecci'on

Ölpumpe für den Schmieröl- und Kühlkreislauf

Oil pump for lubricating oil and cooling oil circuits

Pompe à huile pour les circuits d'huile de graissage et de refroidissement

Bomba para aceite lubricante y refrigerante

Verbrennungsluftansaugleitung

Air intake mainfold

Collecteur d'admission

Colector de admisión

Integriertes Kühlgebläse mit Schutzgitter

Integrated Colling Fan with Guard

Ventilateur de refroidissement intégré

avec grille de protection

Ventilador de refrigeración integrado,

con rejilla de protección

Generator

Alternator

Alternateur

Generador

Drehzahlregler

Speed governor

Régulateur de vitesse

Regulador de velocidad

Permanentspannrolle

Permanent tension pulley

Galet-tendeur permanent

Polea tensora permanente

Zahnriemen für Motorsteuerung

Toothed belt for engine timing

Courroie dentée pour la distribution

Correa dentada para distribución del motor

Kolben mit eingezogener Brennraum-Mulde

Piston with re-entrant type bowl

Piston avec alvéole omega

Pistón con cámera de combustión