i

CONTENTS

About This Manual..................................................................................................................... iii

Formatting and Typography....................................................................................................iii

Technical Assistance—Help! ..................................................................................................iii

Chapter 1. Safety.........................................................................................................................1

Safety Warnings......................................................................................................................1

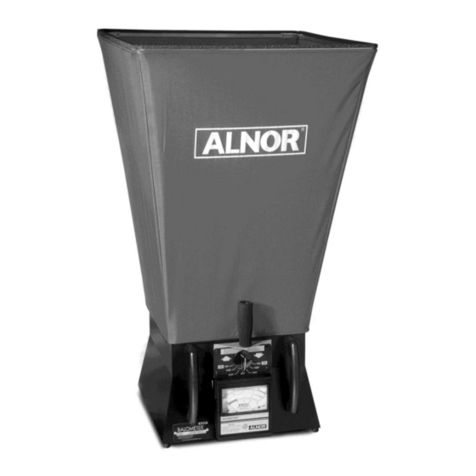

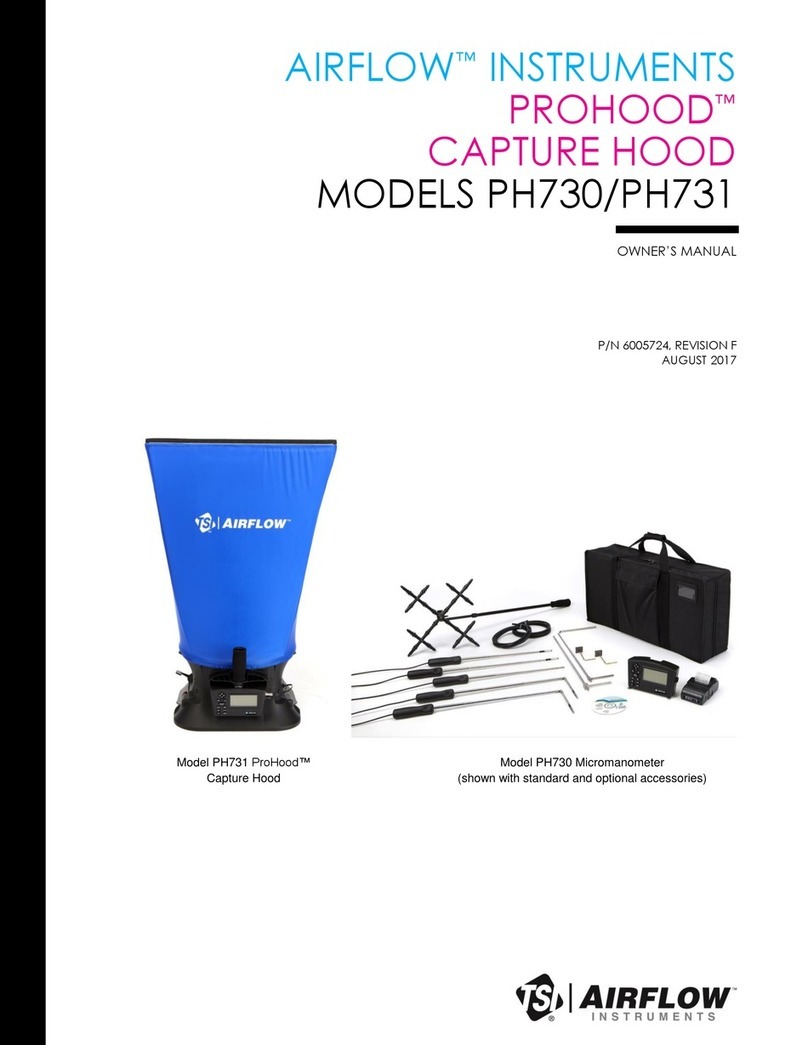

Chapter 2. Introduction ..............................................................................................................3

Instrument Description............................................................................................................3

Unpacking...............................................................................................................................4

Chapter 3. Getting Started ......................................................................................................... 5

Keypad....................................................................................................................................5

Powering the Instrument.........................................................................................................6

Using the AC Adapter .......................................................................................................6

Installing the Batteries.......................................................................................................6

Instrument Start-up .................................................................................................................7

Zeroing the Manometer...........................................................................................................7

Zeroing the Gauge Pressure Sensor ................................................................................7

Zeroing the Differential Pressure Sensor..........................................................................8

Connecting the Manometer to the Test Points........................................................................8

Attaching the Hoses to the Manometer.............................................................................8

Bleeding the Entrained Air ................................................................................................8

Attaching the Hoses to the Test Points.............................................................................9

Making Pressure Measurements ............................................................................................9

Accessing the Pressure Measurement Screen.................................................................9

Pressure Measurement Screen ........................................................................................9

Continuous Measurements.............................................................................................10

Making Flow Measurements.................................................................................................10

Accessing the Flow Measurement Screen......................................................................10

Flow Measurement Screen .............................................................................................10

Making Temperature Measurements....................................................................................11

Connecting the Temperature Probe................................................................................11

Setting Units of Measure.......................................................................................................11

Storing Discrete Measurements............................................................................................11

Disconnecting the Manometer from the Test Points.............................................................12

Chapter 4. Main Menu............................................................................................................... 13

Zero Gauge Pressure............................................................................................................13

Select Cv/Kv Factor ..............................................................................................................13

Select Fluid ...........................................................................................................................13

Water...............................................................................................................................13

Other...............................................................................................................................13

Edit Current Cv/Kv Factor.....................................................................................................14

Set K Factors-Offsets............................................................................................................14

dP K Factor.....................................................................................................................14

Gauge K Factor...............................................................................................................14

Temperature Offset.........................................................................................................14

Set Date and Time................................................................................................................14