Installation Guide

Alpha Instruments Model 178

Differential Pressure Transducers

EveryModel 178 has been tested and calibrated before shipment.

Alpha Instruments M178 pressure transducers sense differential or gauge (static) pressure and convert

this pressure difference to a proportional high level analog output for both unidirectional and bidirectional

pressure ranges. The standard output is 4 to 20mA.

Media Compatibility:

Model 178 transducers are designed to be used with air or non-conducting gases. Use with liquids or

highlycorrosive gases may damage the unit.

Environmental Requirement:

Operating Temperature 0 ~170oF (-18 ~77℃)

Compensated Temperature Range 35 ~170 oF (2 ~77℃)

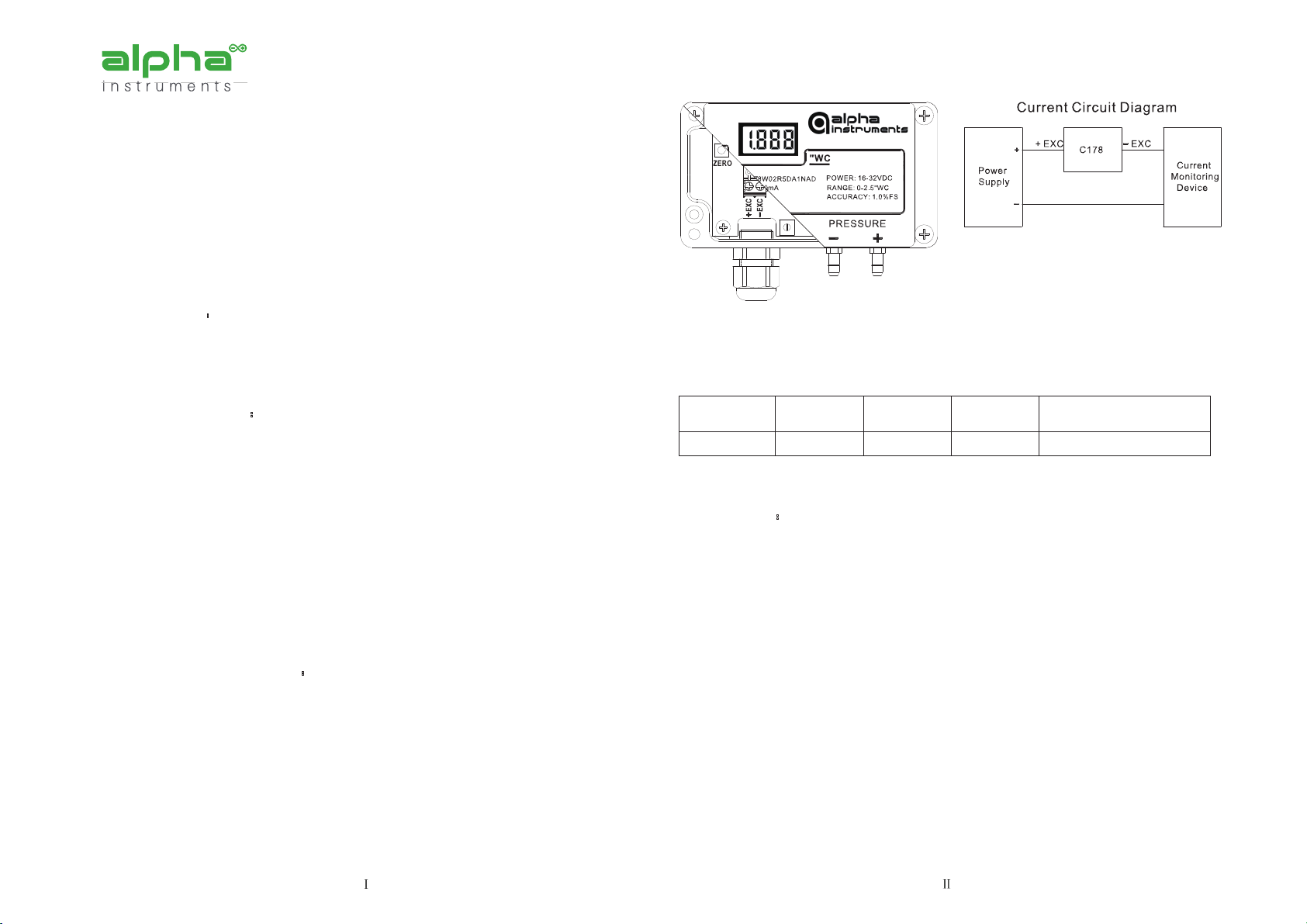

Pressure Fittings:

The standard Model 178 is to be used with 3/16” I.D. push-on tubing. 8mm barbed brass pressure fittings

and other possible pressure fittings are optional. The positive (high) pressure port and the reference (low)

pressure port are labeled as " + "and "- " respectively. For best results(quick response), the suggested

length of 3/16” I.D. tubing is less than 82 feet (25 meters), 1/4” I.D. tubing is less than 246 feet (75

meters).

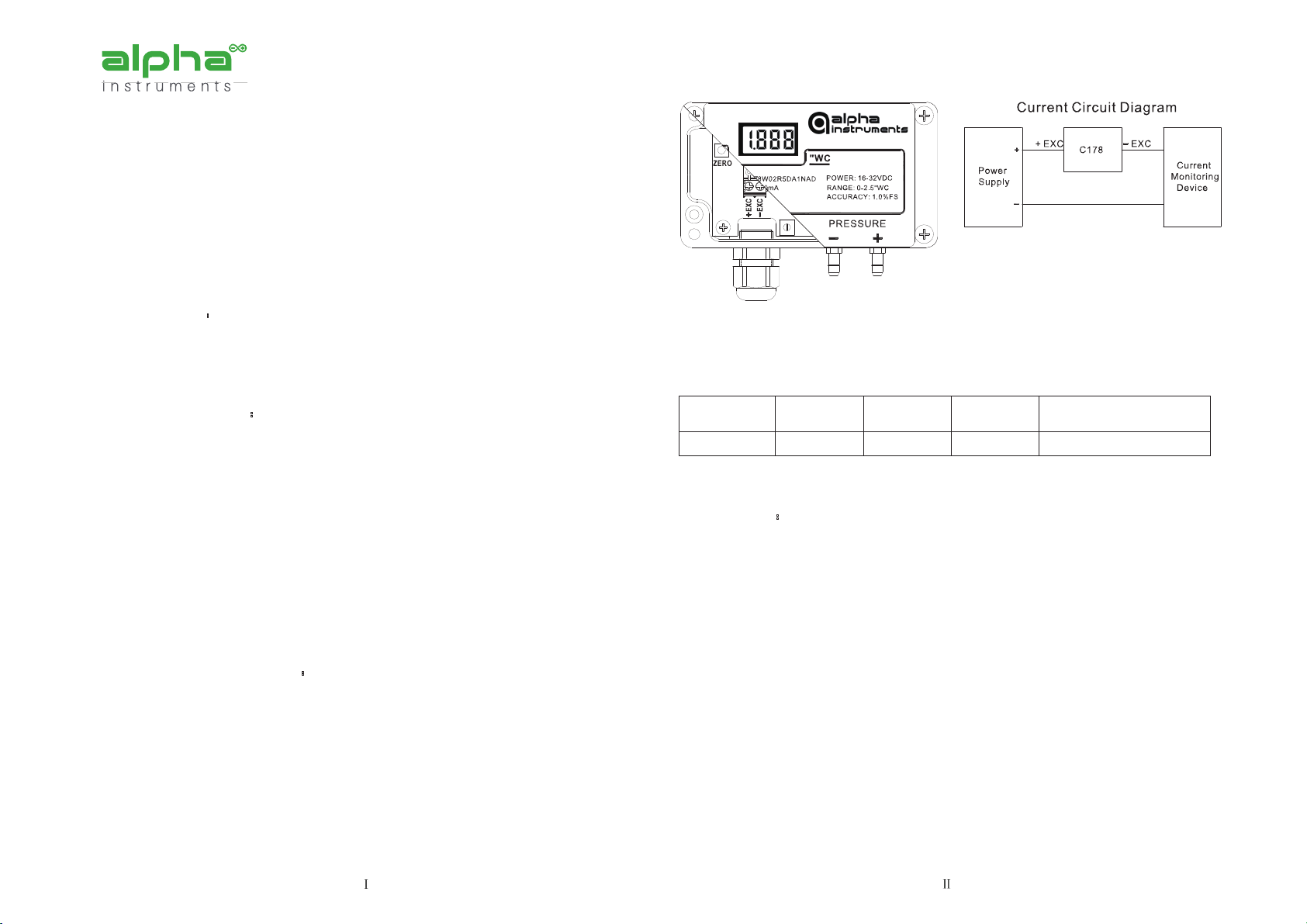

Electrical Installation(Current Output):

The Model 178 is a two-wire loop-powered 4 to 20mA current output unit and delivers rated current into

anyexternal load of 0 to 800 ohms. The detachable terminal block accepts 16 to 26 AWG wires. It has

thedesignation of “+EXC” and“-EXC“ (See Diagram 1). The current flows into the“+EXC” terminal and

returns back to the power supply through the “-EXC“ terminal (See Diagram 2). The 178 can operate

from 16-32VDCpower supply. The factorycalibration is performed with a 24 VDC power supply and a

250ohmload.

Diagram 1Diagram 2

The below table shows the maximum wire and receiver resistances as a function of supplyvoltage.

Vmin VmaxRmin Rmax RL atSupply Voltage (Vs)

16 32 0 800 RL≤50(Vs-16)

For Example:Voltage is 24VDC,RL≤50(24-16)=400Ω,the load resistance should not exceed 400Ω。

Zero Calibration:

1. After 178 transducer is installed, keep power on for one minute or longer to eliminate the warm up

shift. Do not applypressure to either pressure port .

2. If the LCDshows “000”. Thereisno need to do the calibration.

3. If the LCD does not show “000”, press “Z” button down. Wait until the LCD shows “000” and 3 more

seconds. Release “Z” button.

The zero output should be:

Unidirectional Pressure Range: 4 mA.

Bidirectional Pressure Range: 12mA