Z202882-0X

Page 1 of 4 ©2019 Veris Industries USA 800.354.8556 or +1.503.598.4564 / suppor[email protected] 1219 Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classied locations.

•

Read and understand the instructions before installing this product.

• Turn o all power supplying equipment before working on it.

• The installer is responsible for conformance to all applicable codes.

If this product is used in a manner not specied by the manufacturer, the protection

provided by the product may be impaired. No responsibility is assumed by the

manufacturer for any consequences arising out of the use of this material.

Installation Guide

Pressure TM

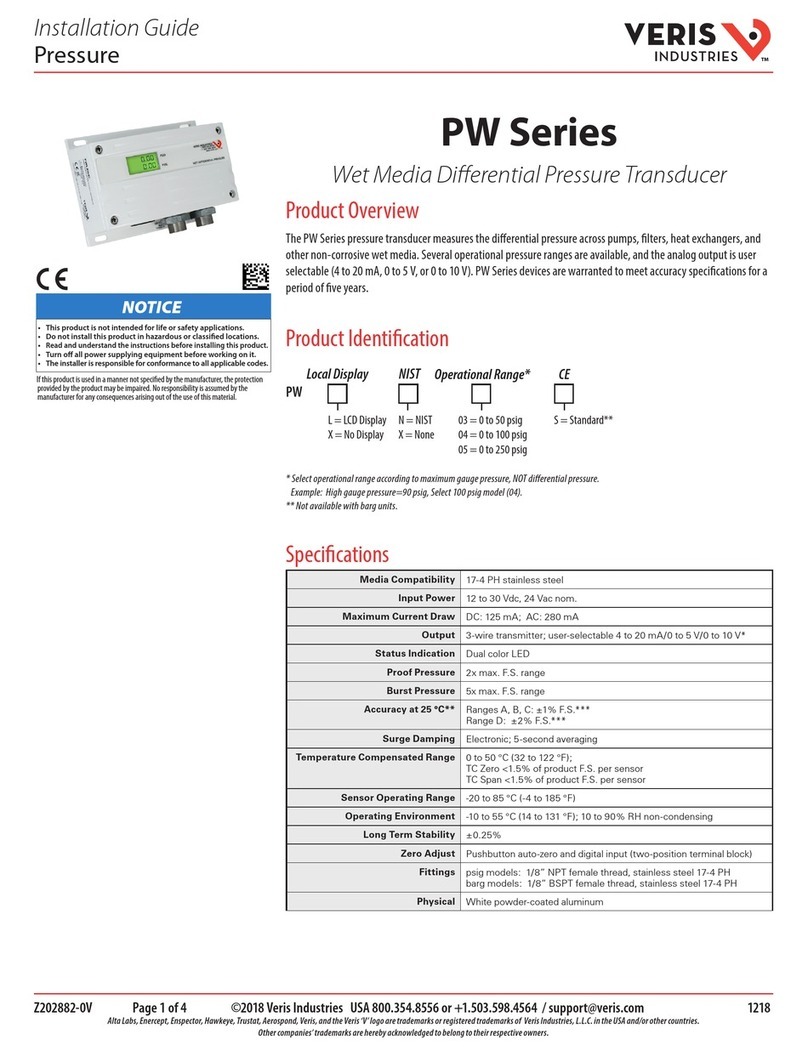

Product Identication

Specications

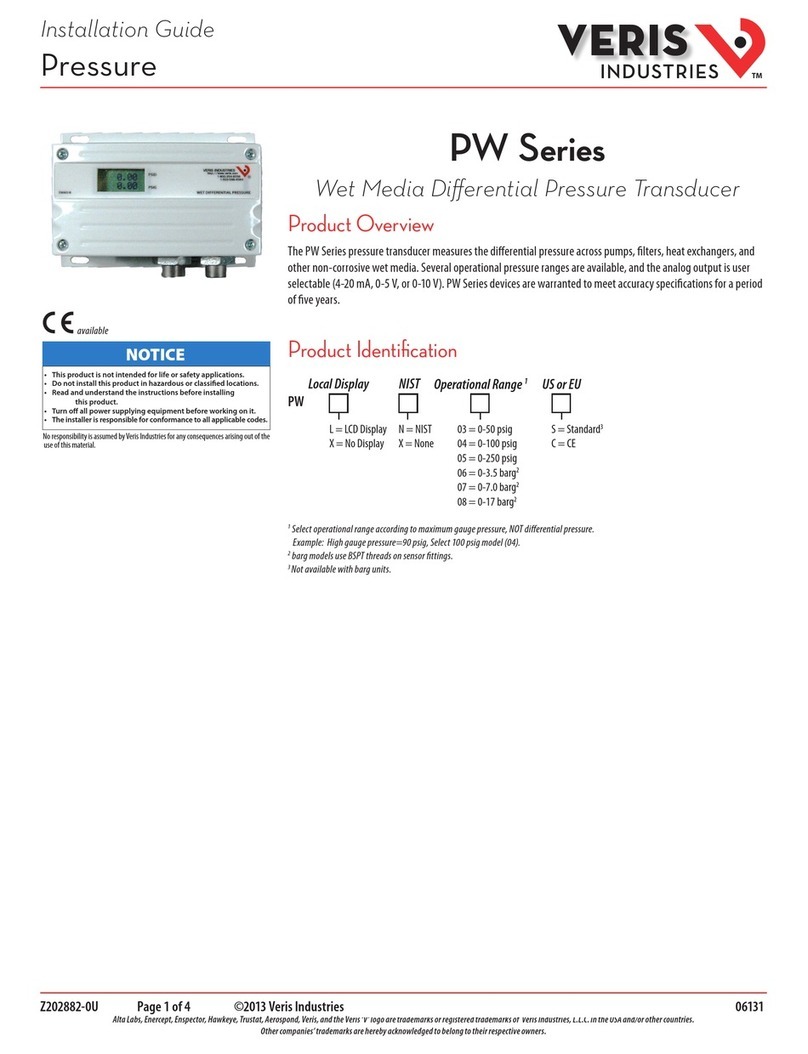

Product Overview

The PW Series pressure transducer measures the dierential pressure across pumps, lters, heat exchangers, and

other non-corrosive wet media. Several operational pressure ranges are available, and the analog output is user

selectable (4 to 20 mA, 0 to 5 V, or 0 to 10 V). PW Series devices are warranted to meet accuracy specications for a

period of ve years.

The optional pre-assembled bypass valve is designed for easy maintenance and one-step installation.

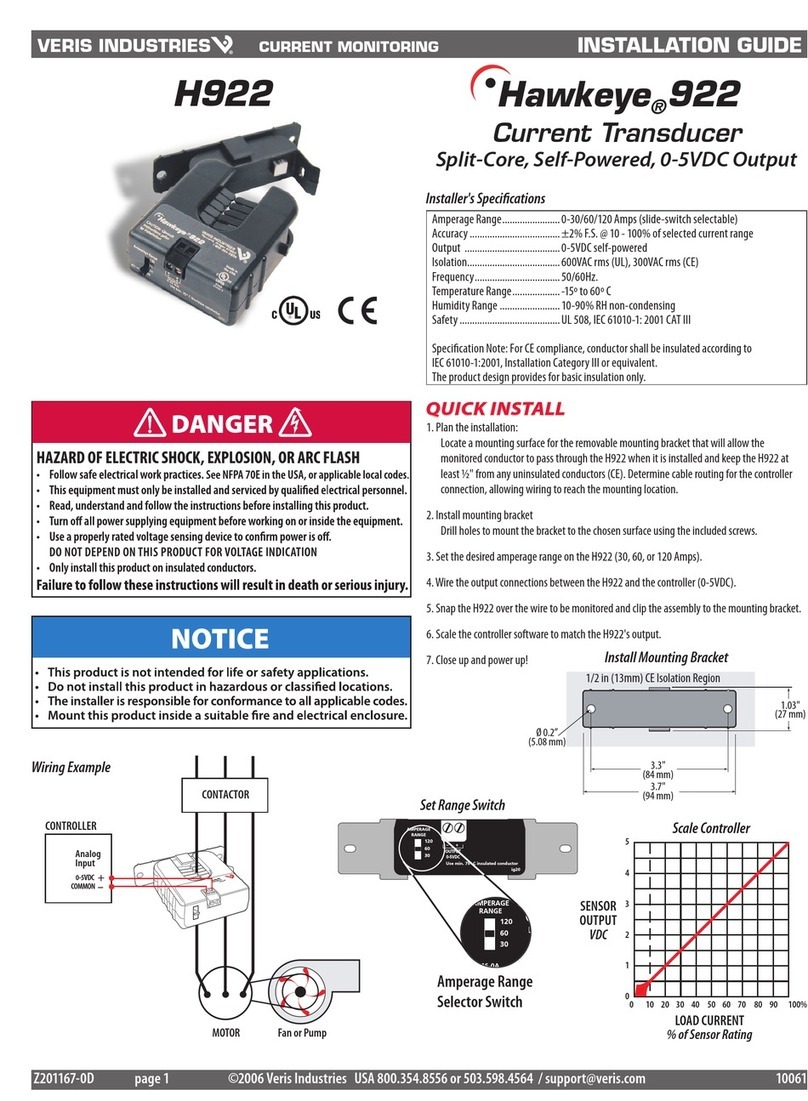

PW Series

Wet Media Differential Pressure Transducer

Local Display

L = LCD Display

X = No Display

NIST

N = NIST

X = None

Options

S = Standard

BP = With mounted bypass assembly

Operational Range*

03 = 0 to 50 psig

04 = 0 to 100 psig

05 = 0 to 250 psig

PW

* Select operational range according to maximum gauge pressure, NOT dierential pressure.

Example: High gauge pressure=90 psig, Select 100 psig model (04).

Media Compatibility 17-4 PH stainless steel

Input Power Class 2; 15 to 30 Vdc, 24 Vac nom. 50/60 Hz*

Maximum Current Draw DC: 125 mA; AC: 280 mA

Output 3-wire transmitter; user-selectable 4 to 20 mA/0 to 5 V/0 to 10 V*

Status Indication Dual-color LED

Proof Pressure 2x max. F.S. range***

Burst Pressure 5x max. F.S. range***

Accuracy at 25 °C** Ranges A and B: ±1% F.S. typical***;

Range C: ±1.5% F.S. typical***;

Range D: ±2% F.S. typical***

Surge Damping Electronic; 1 or 5 second averaging

Temperature Compensated Range 0 to 50 °C (32 to 122 °F);

TC Zero <1.5% of product F.S.*** per sensor

TC Span <1.5% of product F.S.*** per sensor

Sensor Operating Range -20 to 85 °C (-4 to 185 °F)

Operating Environment -10 to 50 °C (14 to 122 °F); 10 to 90% RH non-condensing

Media Temp. Limits -20 to 85 °C (-4 to 185 °F); 0 to 90% RH non-condensing

Long Term Stability ±0.25%

Zero Adjust Pushbutton auto-zero and digital input (two-position terminal block)

Zero Oset

(Bidirectional and Port Swap modes only)

0.5%

Fittings 1/8” NPT female thread, stainless steel 17-4 PH

Physical White powder-coated aluminum, NEMA 4, IP65

PWxxxS

PWxxxBP