Installation

1. Run wire to be monitored through sensor aperture. Be sure

themonitoredcurrentowisinaccordancewithany

directional arrows on sensor.

2. Mount the transducer to a surface if needed. They can be

mounted in any position or hung directly on wires with a wire

tie. Just leave at least 30 mm distance between sensor and

other magnetic devices.

3. Connect output wiring to deadfront captive screw terminals

and observe polarity. Use up to 2.5 mm2(14 AWG) copper

wires. Tighten terminals to 0.6 Nm (5 in-lbs) torque.

- for current output models (mA), make sure output load is

no more than 500 W.

- for voltage output models (VDC), make sure output load is

at least 25 kW.

4. Connect the appropriate power supply. For optimal perfor-

mance, ensure unit has been ernergized for a period of 20

minutes prior to sensing operation.

5. Select the range that is equal to or slightly higher than the

normal operating amperage of monitored circuit. Place the

range jumper in the appropriate position.

Trouble shooting

1. Output Signal Too Low

- The jumper may be set in a range that is too high for current

being monitored. Move jumper to the correct range.

- Power supply is inadequate. Check power supply. Make

sureitisofsufcientvoltagewithallloadsatmaximum.

DK series consumes 2.0 VA.

For 0-20 mA, 4-20 mA Models

- Output load too high. Check output load, be sure it is no

more than 500 W.

For 0-5, 0-10 VDC Models

- Output load too low. Check output load, be sure it is at

least 25 kW.

2. Output Signal is always at maximum

- The jumper may be set in a range that is too low for current

being monitored. Move jumper to the correct range.

3. Sensor has not output

- Polarity is not properly matched. Check and correct wiring

polarity.

- Monitored load is not DC or is not on. Check that the

monitored load is DC and that it is actually on.

- Split Core models: The core contact area may be dirty.

Open the sensor and clean the contact area.

16September2013/Version 8

Safety and warning notes

Safe operation can only be guaranteed if the transducer is used

for the purpose it has been designed for and within the limits of

thetechnicalspecications.

Caution! Risk of danger

Ignoring the warnings can lead to serious injury and/or cause

damage!

The electric measuring transducer may only be installed and

putintooperationbyqualiedpersonnelthathavereceivedan

appropriate training.

The corresponding national regulations shall be observed during

installation and operation of the transducer and any electrical

conductor.

The transducer shall be used in electric/electronic equipment

with respect to applicable standards and safety requirements

and in accordance with all the related systems and components

manufacturers’ operating instructions.

Caution! Risk of electrical shock

When operating the transducer, certain parts of the module may

carry hazardous live voltage (e.g. primary conductor, power

supply).

The user shall ensure to take all measures necessary to protect

against electrical shock.

The transducer is a built-in device containing conducting parts

that shall not be accessible after installation.

A protective enclosure or additional insulation barrier may be

necessary.

The transducer shall not be put into operation if the jaw opening is

open (split core version) or the installation is not completed.

Installation and maintenance shall be done with the main power

supply disconnected except if there are no hazardous live parts in

or in close proximity to the system and if the applicable national

regulations are fully observed.

At the heart of power electronics

LEM is the market leader in providing innovative and high quality

solutions for measuring electrical parameters. Its core products

current and voltage transducers are used in a broad range

of applications in industrial, traction, energy, automation and

automotive markets.

For more information: www.lem.com

LEM S.A.

8, chemin des Aulx

CH-1228 Plan-les-Ouates

Switzerland

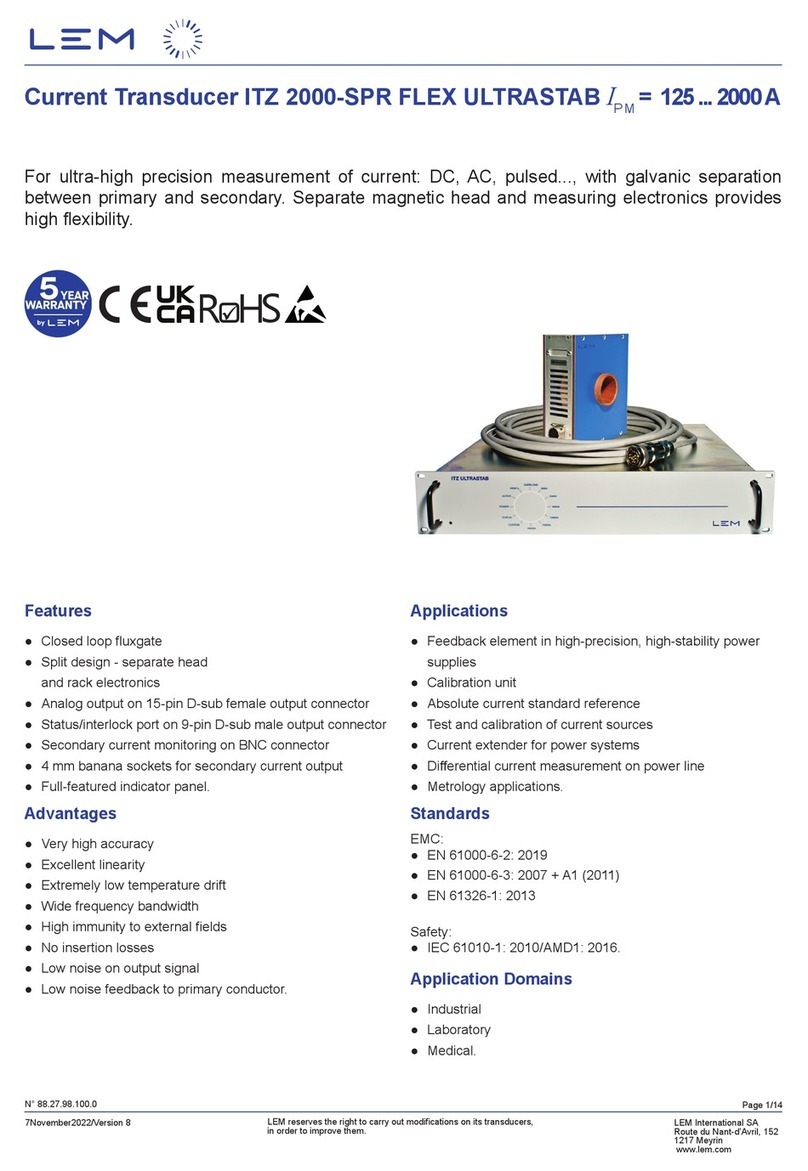

Connection diagram

DK Split core version DK Solid core version

Output polarity and primary current direction

For correct transducer mounting, please refer to the appropriate

datasheet for the respective positive current direction and transfer

characteristics of the:

- standard unipolar output version (magnitude only)

- unidirectional version (“U” option)

- bi-directional version (“B” option).

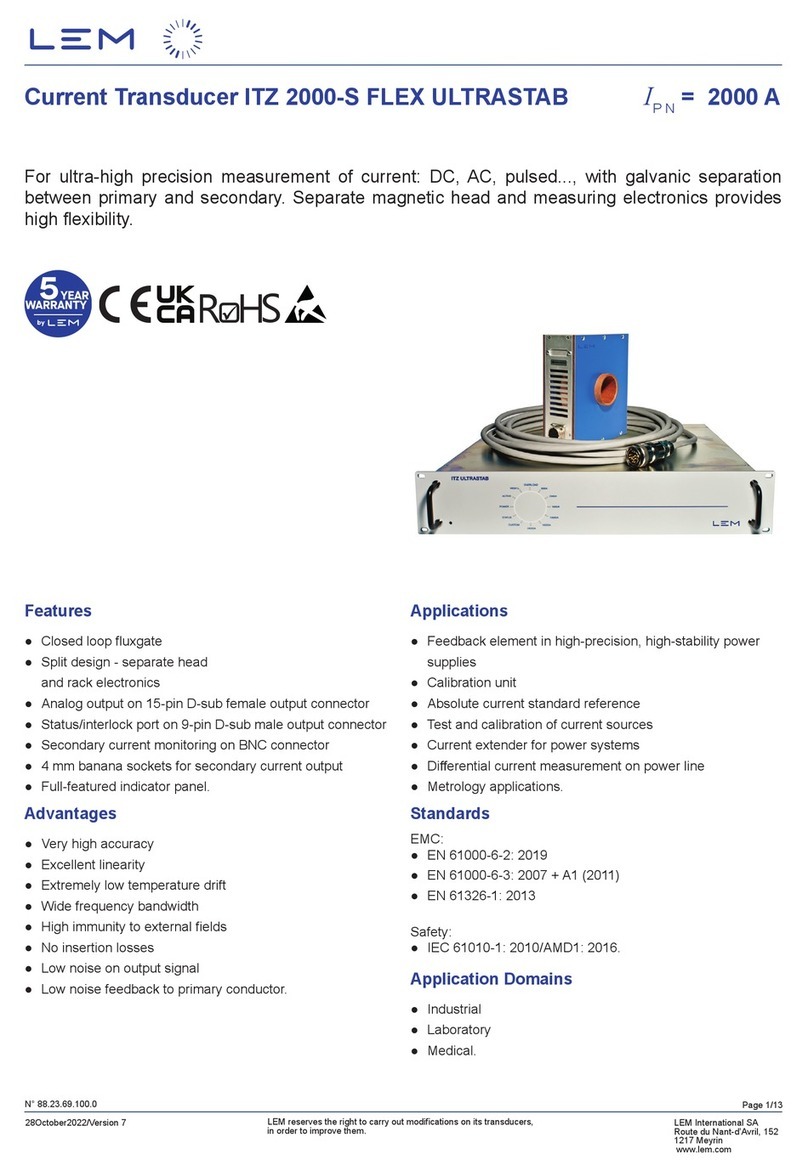

Split-core model

Press the tab in the direction as

shown to open the sensor.

After placing the wire in the

opening, press the hinged portion

rmlydownwarduntiladenite

click is heard and the tab pops

out fully.

Silicone grease is factory applied on the mating surfaces to

prevent rust and improve performance.

Be careful not to allow grit or dirst onto the grease in the contact

area. Operation can be impaired if the mating surfaces do not

have good contact. Check visually before closing.

Isolation characteristics

UbRated insulation voltage rms,

reinforced insulation, CAT III, PD2 150 V

If isolated cable is used for the primary circuit, the

voltage category could be improved according to

the following table:

Cable isolation (primary) Category

HAR 03 300 V CAT III

HAR 05 600 V CAT III

HAR 07 1000 V CAT III

UdRms voltage for AC insulation test,

50Hz, 1 min 3 kV

ULXX Plasticcaseclassication UL94-V0

1(-) 2(+) 3(-) 4(+)

Power Output

Range

Jumper High

(-) (+)

Power Supply

20-45 VDC

(+)

Load

(Controller,

Meter, Etc).

(-)

Range

Jumper Measuring

None Low

Mid Medium

High High

Mid

:

1(-) 2(+) 3(-) 4(+)

Power Output Range

Jumper

High

(-) (+)

Power Supply

20-45 VDC

(+)

Load

(Controller,

Meter, Etc).

(-)

MidLow