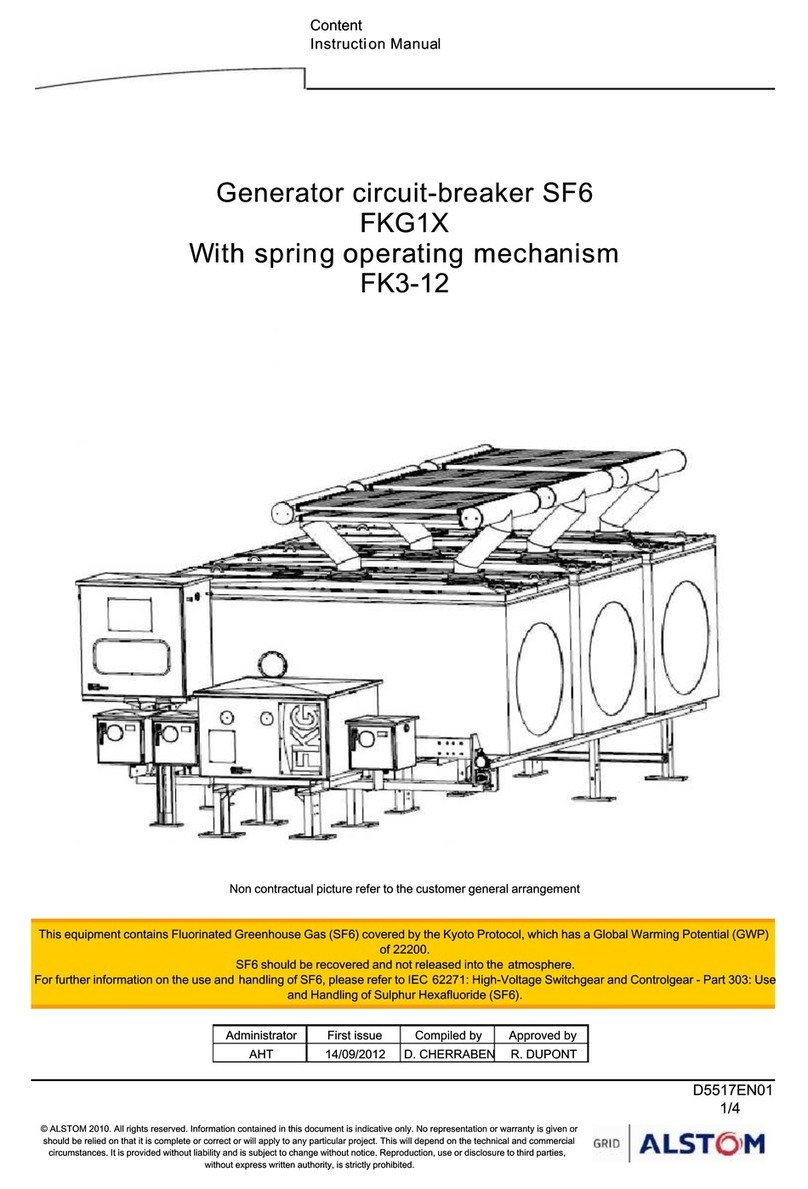

Description and operation

General description of the circuit--breaker

L12--0012EN/01

2/6

11--2012

©ALSTOM 2010. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be relied on

that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is provided without

liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is strictly prohibited.

GRID

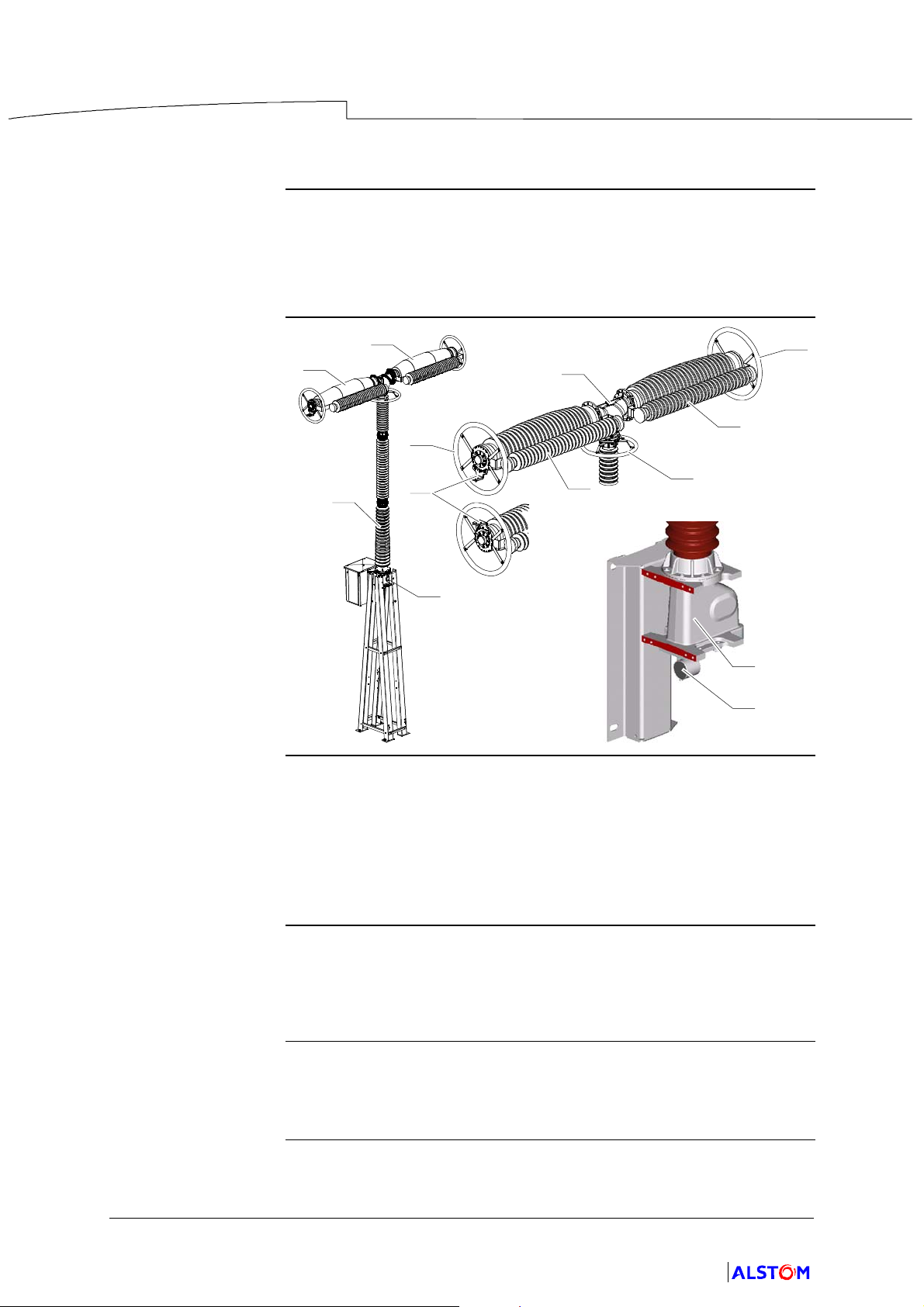

Pole of the circuit--breaker

Description The pole of the circuit--breaker is made up with three main components :

SThe interrupting chambers (1).

SThe support column (2).

SThe housing of the mechanism (3).

Diagram

6

7

4

4

5713

3

8

3

2

1

1

Interrupting

chambers

The pole is comprised of two interrupting chambers (1) -- in a ceramic envel-

ope -- equipped at each end with a HV terminal (5).

The interrupting chambers are laid out horizontally and attached, at their

base, to a common housing (6). This housing contains the mechanism used

to transfer the operating movement to the mobile contacts of both chambers.

The interrupting can also be equipped with capacitors (7) and a corona ring

(4).

Support column Consisting of two, three or four ceramic insulators, the support column allows

the circuit--breaker to be ground--insulated and it also encloses the operating

tie--rod which is attached to the interrupting chamber’s moving contacts.

The support column can also be equipped with a corona ring (13).

Housing of the

mechanism

A housing (3) -- situated at the base of the column -- contains the lever and

crank assembly and which operates the moving contact.

The SF6filling and monitoring device (8) is also situated on the housing.