Allis-Chalmers FB-500A-FC-750A User manual

Other Allis-Chalmers Circuit Breaker manuals

Allis-Chalmers

Allis-Chalmers LA-600 User manual

Allis-Chalmers

Allis-Chalmers LA-600 User manual

Allis-Chalmers

Allis-Chalmers LA 3000 User manual

Allis-Chalmers

Allis-Chalmers MA-75B User manual

Allis-Chalmers

Allis-Chalmers MA-75 User manual

Allis-Chalmers

Allis-Chalmers LA-600 User manual

Allis-Chalmers

Allis-Chalmers LA-25 Installation manual

Allis-Chalmers

Allis-Chalmers LA-1600 User manual

Allis-Chalmers

Allis-Chalmers LA-1600 User manual

Popular Circuit Breaker manuals by other brands

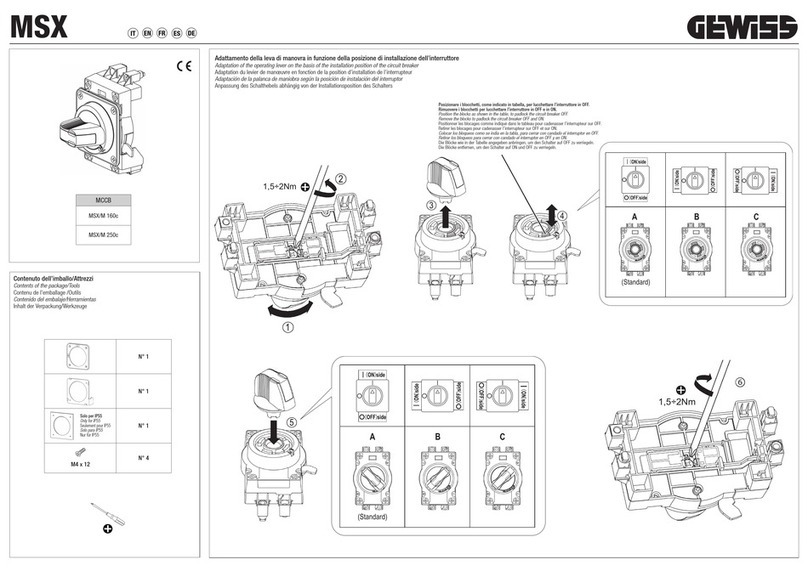

Gewiss

Gewiss MSX/M 160c quick start guide

Moeller

Moeller MSWA-NZM 7 installation instructions

Siemens

Siemens Sentron LMD6 Series Information and Instruction Guide

CHINT

CHINT NB1-63H/2 User instruction

Eaton

Eaton DSII Series Instructions for installation, operation and maintenance

Stahl

Stahl 8562/5 operating instructions