2

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, machines or equipment, basic safety

precautions should always be followed to reduce the risk of fire, electric

shock, and personal injury.

READ ALL INSTRUCTIONS BEFORE USING THIS TOOL

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don’t use power tools in damp,

wet, or poorly lit locations. Don’t expose your tool to rain. Keep the work area

well lit. Don’t use tools in the presence of flammable gases or liquids.

3. KEEP CHILDREN AND BYSTANDERS AWAY. All children should be kept

away from the work area. Don’t let them handle machines, tools or extension

cords.

Visitors can be a distraction and are difficult to protect from injury.

4. GROUNDED TOOLS must be plugged into an outlet that itself is properly

installed and grounded. Grounding provides a low-resistance path to carry

electricity away from the operator. Should the tool malfunction electrically.

Do not remove the grounding prong from the plug or alter the plug in any way

If in doubt as to whether the outlet is properly grounded according to code,

check with a qualified electrician.

5. OBSERVE PROPER PRECAUTIONS REGARDING DOUBLE INSULA-

TION. This tool is double insulated. It is equipped with a polarized plug.

One blade is wider than the other, so it will fit into a polarized outlet only one

way. If you have difficulty inserting the plug, try reversing it. If it still doesn’t

fit , do not alter the plug; have a qualified electrician install a polarized outlet.

6. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces: pipes, radiators, ranges, and refrigerator enclosures. When your

body is grounded the risk of electric shock increases. When working wher-

ever “live” electrical wires may be encountered, try to ascertain whether

there is a danger of shock. Even so, DO NOT TOUCH ANY METAL PARTS

OF THE TOOL while using it. Hold the tool only by the plastic grip to prevent

electric shock if you contact a live wire.

7. DO NOT ABUSE THE CORD. Never carry your tool by the cord or pull on

the cord to unplug it. Protect the cord from potential sources of damage:

heat, oil & solvents, sharp edges, or moving parts. Replace damaged cords

immediately.

8. WHEN WORKING OUTDOORS, USE AN OUTDOOR-RATED EXTENSION

CORD. An extension cord rated for outdoor use must be marked “W-A” or

“W”.

9. DO NOT EXPOSE ELECTRICAL POWER TOOLS TO MOISTURE. Rain or

wet conditions can cause water to enter the tool and lead to electric shock.

10. ENSURE THE EXTENSION CORD YOU USE IS OF SUFFICIENT GAUGE

FOR ITS LENGTH.

11. STORE IDLE EQUIPMENT. Store equipment in a dry area to inhibit rust.

Equipment also should be in a high location or locked up to keep out of

reach of children.

12. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

13. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

work of a larger industrial tool. Don’t use a tool for a purpose for which it was

not intended.

14. DRESS PROPERLY. Don’t wear loose clothing or jewelry; they can be

caught in moving parts. Protective, non-electrically conductive gloves and

non-skid footwear are recommended when working. Wear protective hair

covering to contain long hair and keep it from harm.

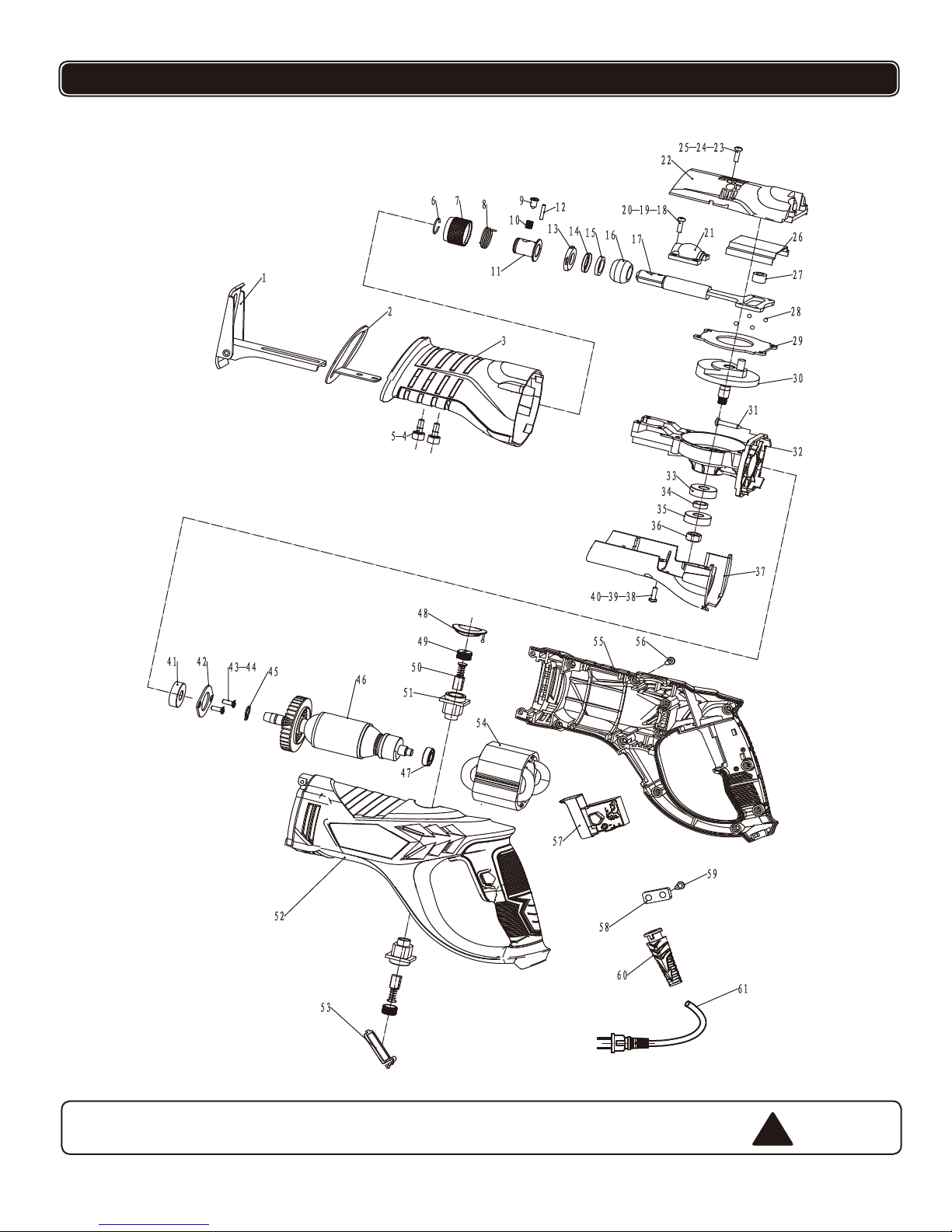

Recommended Minimum Wire Gauge for Extension Cords

Amps

from

Tool Nameplate

25’ length 50’ length 75’ length 100’ length 150’ length 200’ length

0-5 amps 16 ga. 16 ga. 16 ga. 14 ga. 12 ga. 12 ga.

5.1-8 amps 16 ga. 16 ga. 14 ga. 12 ga. 10 ga. Do Not Use

8.1-12 amps 14 ga. 14 ga. 12 ga. 10 ga. Do Not Use Do Not Use

12.1-15 amps 12 ga. 12 ga. 10 ga. 10 ga. Do Not Use Do Not Use

15.1-20 amps 10 ga. 10 ga. 10 ga. Do Not Use Do Not Use Do Not Use