Important Safety Information

About Ground Wires

In the event of an electrical short circuit, a

ground wire reduces the risk of electric

shock by providing an escape wire for the

electric current.

Standard accepted color coding tbr ground

wires is green or green with ayellow

stripe.

Grounding wires and wires colored like

grounding wires are NOT to be used as

current carrying conductors.

] WARNING I

To reduce the risk of fire, the dryer

MUST be exhausted to the outdoors.

DO NOT exhaust dryer air into a

window well, gas vent, chimney or

enclosed, unventilated area, such as

an attic, wall, ceiling, crawl space

under a building or concealed space

of a building.

] WARNING I

To reduce the risk of fire, DO NOT

use plastic pipe, foil pipe, or flexible

plastic pipe to exhaust the dryer.

Never install flexible duct in

concealed spaces, such as a wall or

ceiling.

] WARNING]

To avoid risk of personal injury or

death:

• Do not allow children to play on or

in the appliance. Close

supervision of children is

necessary when the appliance is

used near children.

Grounding Instructions

This dryer must be connected to a grounded metal, permanent wiring system,

or an equipment-grounding conductor must be run with the circuit conductors

and connected to the equipment-grounding terminal or lead on the dryer.

• Power cord (pigtail) is not supplied with electric dryer. Type of pigtail and

gauge of wire must conform to local codes and instructions.

Method of wiring dryer is optional and subject to local code requirements.

• Connect dryer to power supply with MAXIMUM RATED VOLTAGE listed on

the nameplate.

• Use copper wire only. Shorter than 15' (4.5 m) use 10 A.W.G. Longer than

15" (4.5 m) use 8 A.W.G.

WARNING ]

To avoid risk of personal injury or death due to electrical shock:

• Observe all local codes and

ordinances.

• Disconnect electrical power to

unit before servicing.

• Ground appliance properly.

• Check with a qualified

electrician if you are not sure

this appliance is properly

grounded.

• DO NOT ground to gas line.

• DO NOT ground to cold water

pipe.

• DO NOT modify plug on

power cord. If plug does not fit

electrical outlet, have proper

outlet installed by qualified

electrician.

• DO NOT have a fuse in the

neutral or ground circuit. A fuse

in the neutral or ground circuit

could result in an electrical

shock.

• DO NOT use an extension cord

with this appliance.

• DO NOT use an adapter plug

with this appliance.

• DO NOT pinch power cord.

I WARNING

To reduce the risk of fire, electric shock, serious injury or death, all wiring

and grounding must conform with the latest edition of the National Electric

Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1, and

such local regulations as might apply. It is the customer's responsibility to

have the wiring and fuses checked by a qualified electrician to make sure

your home has adequate electrical power to operate the dryer.

] ,Jib WARNING I

To avoid injury or death due to

suffocation, remove door to dryer

compartment before appliance is

removed from service or discarded.

Installation Requirements Install

Consider

Location

Electrical Reauirements

Exhaust

Description

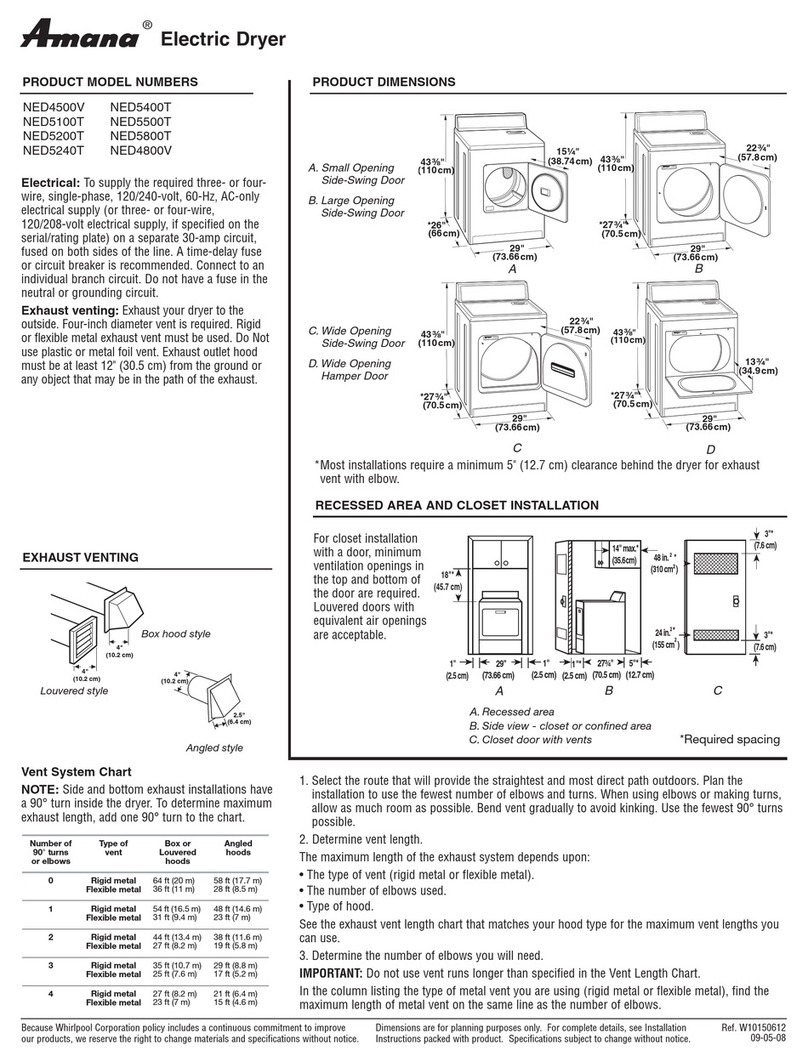

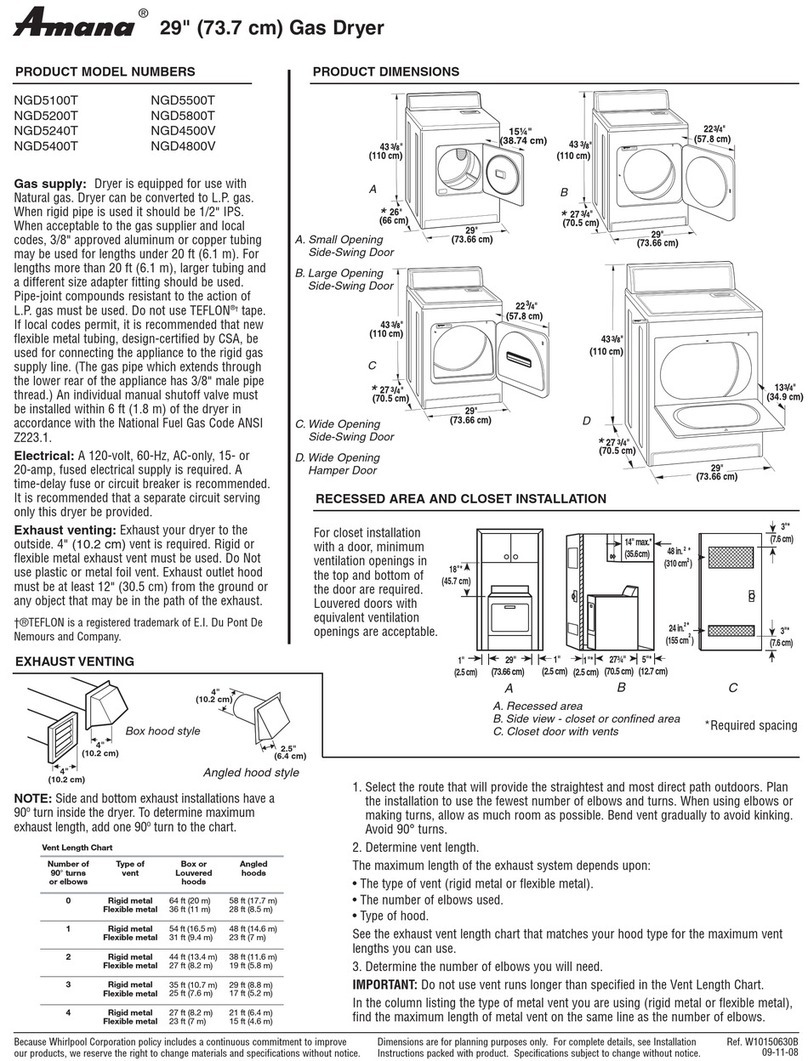

Use dimensions shown in manual to determine space needed for installation.

Place dryer on a solid floor in an area with an adequate air supply. A Closet door

must have two supply air vents with a minimum of 40sq. in. (260 sq. cm) each

(see diagram).

Dryer must not be installed or stored in an area where it will be exposed to water

and/or weather.

Leveling legs can be adjusted from inside the dryer with a 1/4"driver. All four legs

must rest firmly on the floor so the weight of the dryer is evenly distributed. The

dryer must not rock.

Dryer needs a 3 or 4 wire 120/240 Volt, 30 amp, 60 Hertz, 1 Phase electrical

supply. Refer to serial plate for specific requirements. Wiring diagram is located

in control hood.

Use rigid or semi-rigid duct and exhaust the dryer to the outside by the shortest

route possible. Failure to exhaust dryer properly will void warranty.

• Dryer exhaust duct must be secured to the mobile home structure. Dryer

exhaust duct MUST NOT terminate under the mobile home.

• Exhaust duct must not be connected to any other duct, vent or chimney.

• Venting materials are not supplied with the dryer (obtain locally). Do not use

plastic or thin foil flexible ducting.

• Static pressure in the dryer's exhaust duct should be no greater than .6 inches

(1.5 cm). Check with dryer running and no load. This can be measured with a

manometer placed on the exhaust duct approximately two feet (61 cm) from

the dryer.

For the best exhaust system

Locate dryer so exhaust duct is as short as possible.

Verify old ducts are cleaned before installing new dryer.

Use 4" (10.2 cm) diameter rigid or flexible metal duct.

Use as few elbows as possible.

Use duct tape on all joints.

Dryer Dimensions and Minimum Clearances

]

._ 23.5"

(59.7crn)

u

7.7" _ cq. -- _====_

.4" (1('.2 cm) i L--

28" (1.1 cm) 26.9"

(71.1 cm) (68.3 cm)

* \Vith leveling legs turned Rlllx into base

o

15.4"

(39.1 cm)

FRONT VIEW

(w/o Closet Door)

SIDE VIEW FRONT VIEW

(Closet Door)

0" ({' cm) {," ({}cm) 2" (5.1 cm) Outer wall of

enclosure

i •

Save These Instructions

Part No.40086104 ¢, 2000 Amana Appliances

Printed in U.S.A. 9/00 Amana, iowa 52204