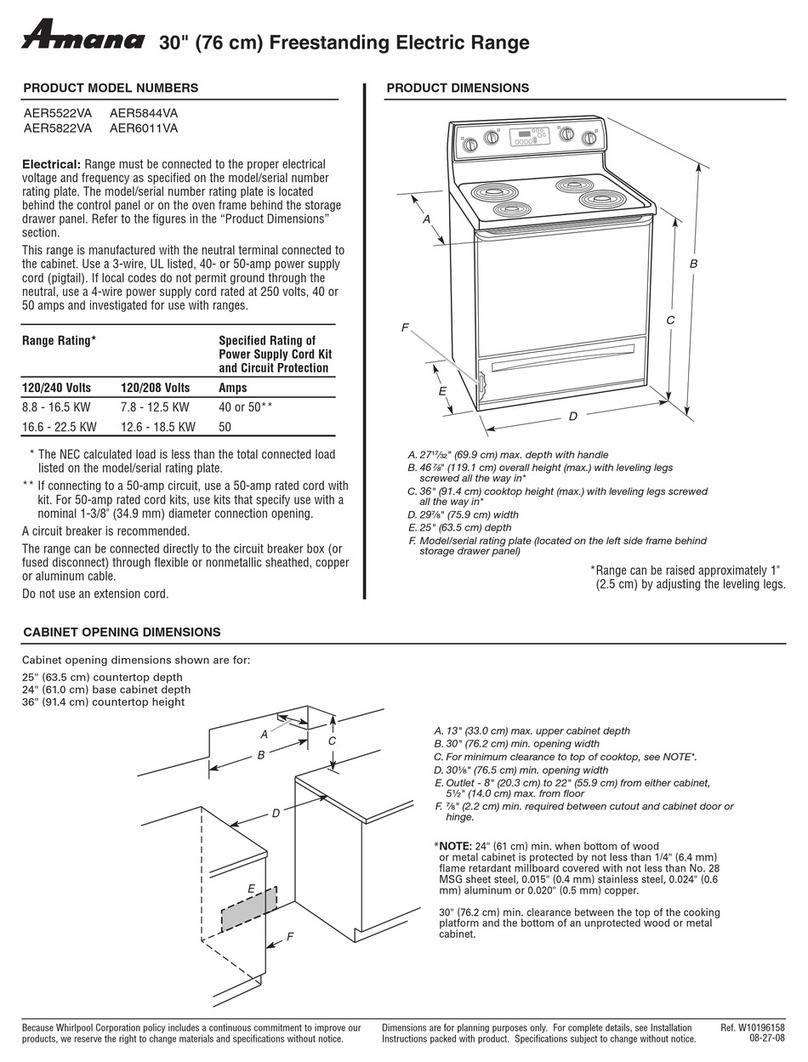

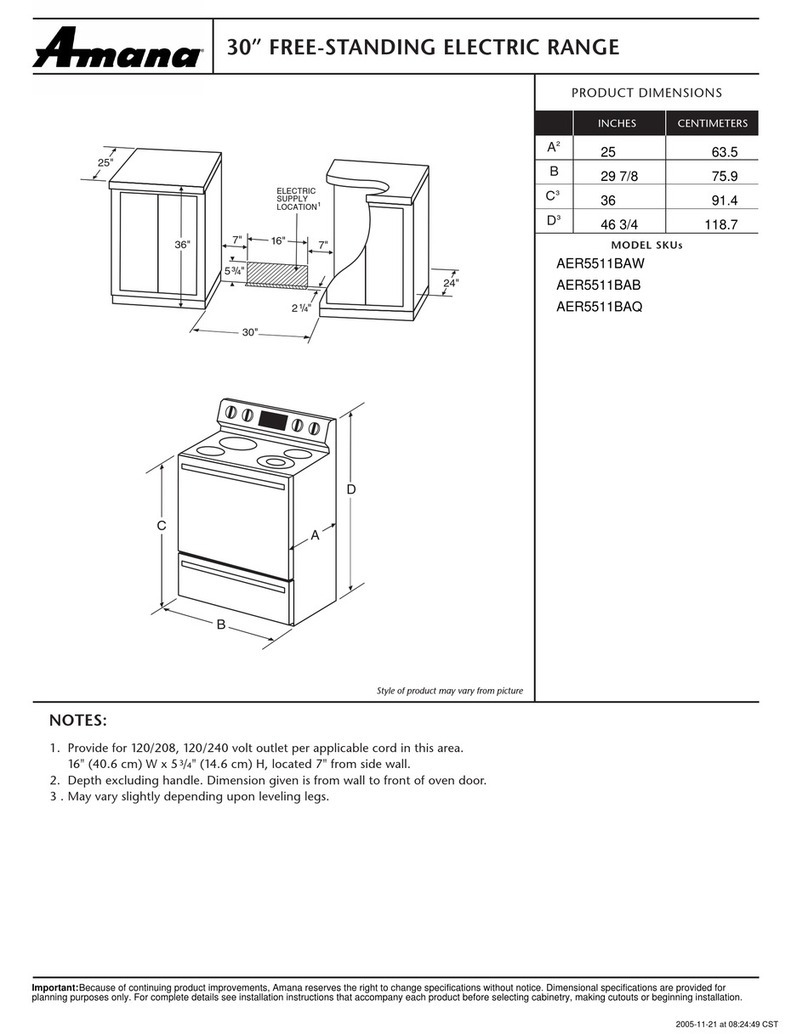

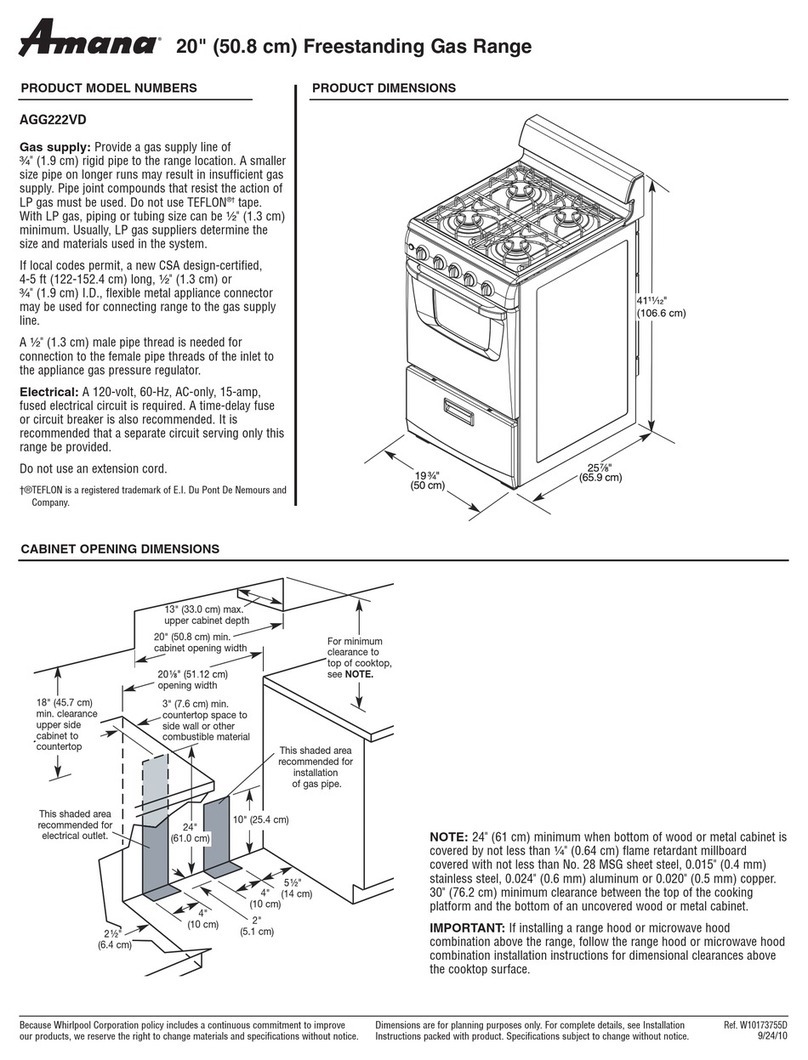

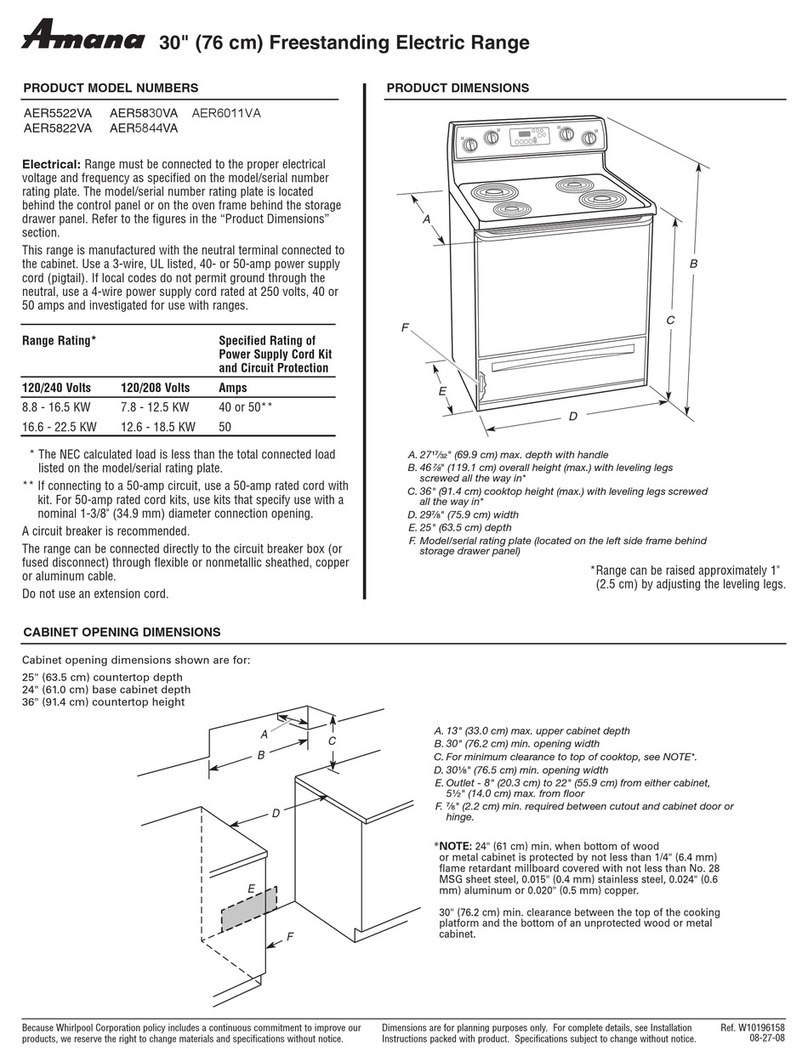

Cabinet Dimensions

Cabinet opening dimensions shown are for 25" (64.0 cm)

countertop depth, 24" (61.0 cm) base cabinet depth and 36"

(91.4 cm) countertop height.

If the cabinet depth is greater than 24" (61.0 cm), oven frame

must extend beyond cabinet fronts by 1/2"(1.3 cm) minimum.

IMPORTANT: If installing a range hood or microwave hood

combination above the range, follow the range hood or

microwave hood combination installation instructions for

dimensional clearances above the cooktop surface.

G

A. 18" (45.7 cm) min. clearance upper side cabinet to countertop

B. 13" (33.0 cm) max. upper cabinet depth

C. 30" (76.2 cm) min. cabinet opening width

D. For minimum clearance to top of cooktop, see NOTE*.

E. 30 _" (76.5 cm) min. opening width

RThis shaded area recommended for installation of electrical outlet.

G. This shaded area recommended for installation of rigid gas pipe.

H. 2" (5.1 cm) min. countertop space to side wall or other combustible

material

I. 24" (61.0 cm)

J. 10" (25.4 cm)

K. 8" (20.3 cm)

L. 5" (12.7cm)

M. 2"(5.1 cm)

N. 3" (7.6 cm)

*NOTE: 24" (61.0 cm) minimum when bottom of wood or metal

cabinet is covered by not less than 1/4"(0.64 cm) flame retardant

millboard covered with not less than No. 28 MSG sheet steel,

0.015" (0.4 mm) stainless steel, 0.024" (0.6 mm) aluminum or

0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance between the top of the

cooking platform and the bottom of an uncovered wood or metal

cabinet.

Electrical Shock Hazard

Plug into agrounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

IMPORTANT: The range must be electrically grounded in

accordance with local codes and ordinances, or in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70,

latest edition.

If codes permit and aseparate ground wire is used, it is

recommended that a qualified electrical installer determine that

the ground path is adequate.

A copy of the above code standards can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, MA 02169-7471

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

• A 120 volt, 60 Hz., AC only, 15-amp fused, electrical circuit is

required. A time-delay fuse or circuit breaker is also

recommended. It is recommended that a separate circuit

serving only this range be provided.

• This range is equipped with a power supply cord having a

3 prong ground plug. To minimize possible shock hazard the

cord must be plugged into a grounded 3 prong outlet.

• Electronic ignition systems operate within wide voltage limits,

but proper grounding and polarity are necessary. Check that

the outlet provides 120-volt power and is correctly grounded.

This range is equipped with an electronic ignition system that

will not operate if plugged into an outlet that is not properly

polarized.

• Performance of this range will not be affected if operated on a

GFCI-protected electrical outlet. However, occasional

nuisance tripping of the GFCI breaker is possible due to the

normal operating nature of electronic gas ranges.

• The wiring diagram is located on the back of the range in a

clear plastic bag.

NOTE: The metal chassis of the range must be grounded in

order for the control panel to work. If the metal chassis of the

range is not grounded, no keypads will operate. Check with a

qualified electrician if you are in doubt as to whether the

metal chassis of the range is grounded.