10

1.6

Ve

nt R

e

qu

i

re

me

nt

s a

nd D

e

t

ails

1.6.1

Un

ve

nt

e

d un

i

t

s

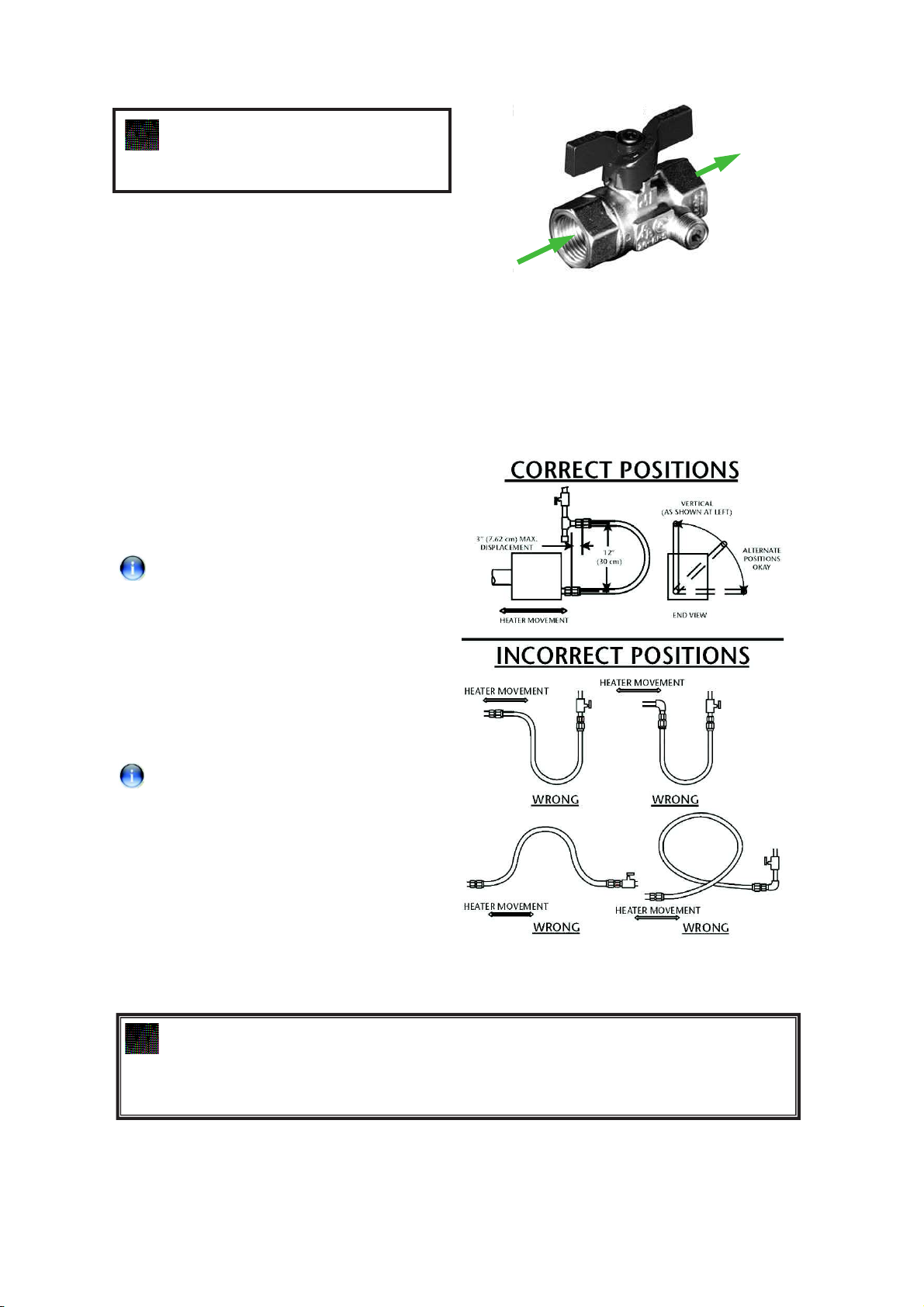

Heaters may be installed without a vent

providing the governing building codes are met

and consideration is properly given to

possibilities of condensation on cold surfaces.

Installation shall meet the following

requirements when unvented:

Natural or mechanical means shall be

provided to supply and exhaust at least 4

CFM per 1000 BTU per hour input of

installed heaters.

Combustion gasses shall not impinge on

combustible materials.

1.6.2

Ve

r

t

ical ve

nt

i

ng

The heater can be installed with a vertical vent.

All vent piping should be adequately supported

from the building structure and terminated with

an approved terminal. Th

e

maxim

u

m

rec

o

mme

nd

e

d

ve

nt

le

ngth

is 25

ft (

7.6m

)

wi

th

a maxim

u

m

of t

w

o

el

bo

ws

. All connections

should be properly sealed. Refer to fig 7a.

1.6.3

Ho

ri

zont

al ve

nt

i

ng

Individual units can be vented horizontally

through side walls. Recommended terminals

are Part Numbers V0700 for 4” and V0800 for

6”.

Distances from adjacent public walkways,

adjacent buildings, openable windows and

building openings, consistent with the N

at

i

ona

l

F

ue

l

Ga

s C

ode,

A

N

SI

Z

223.1/

NF

PA 54

or the

N

atu

r

a

l

Ga

s

and P

r

opane In

s

ta

ll

at

i

on

C

ode,

C

SA B149.1.

Maximum length of vent is 25ft (7.6m) with two

- 90° elbows.

Runs of 12ft (3.6m) or shorter can use

4” (101mm) dia vent. Runs over 12ft (3.6m)

should use 6” (152mm) vent pipe.

Any portion of vent that passes through a

combustible wall must be insulated, or use an

approved insulating thimble.

Standard vent terminals must extend at least

6” (152mm) from the wall and at least

24” (609mm) from any combustible overhang.

This protects the building material from

degradation by the vent gasses.

Vent joints should be sealed and secured

according to the vent manufacturers

instructions. Should condensation occur the

vent should be shortened or insulated.

The terminal should be at least 3ft (0.91m) away

from any air intake to the building.

If the heater is equipped with ducted combustion

air, the vent terminal must be at least 3ft

(0.91m) away from the air inlet and located

higher than the inlet.

The vent terminal must be installed at a suitable

height above the ground to prevent blockage by

snow.

1.7

F

res

h A

ir I

nt

ake

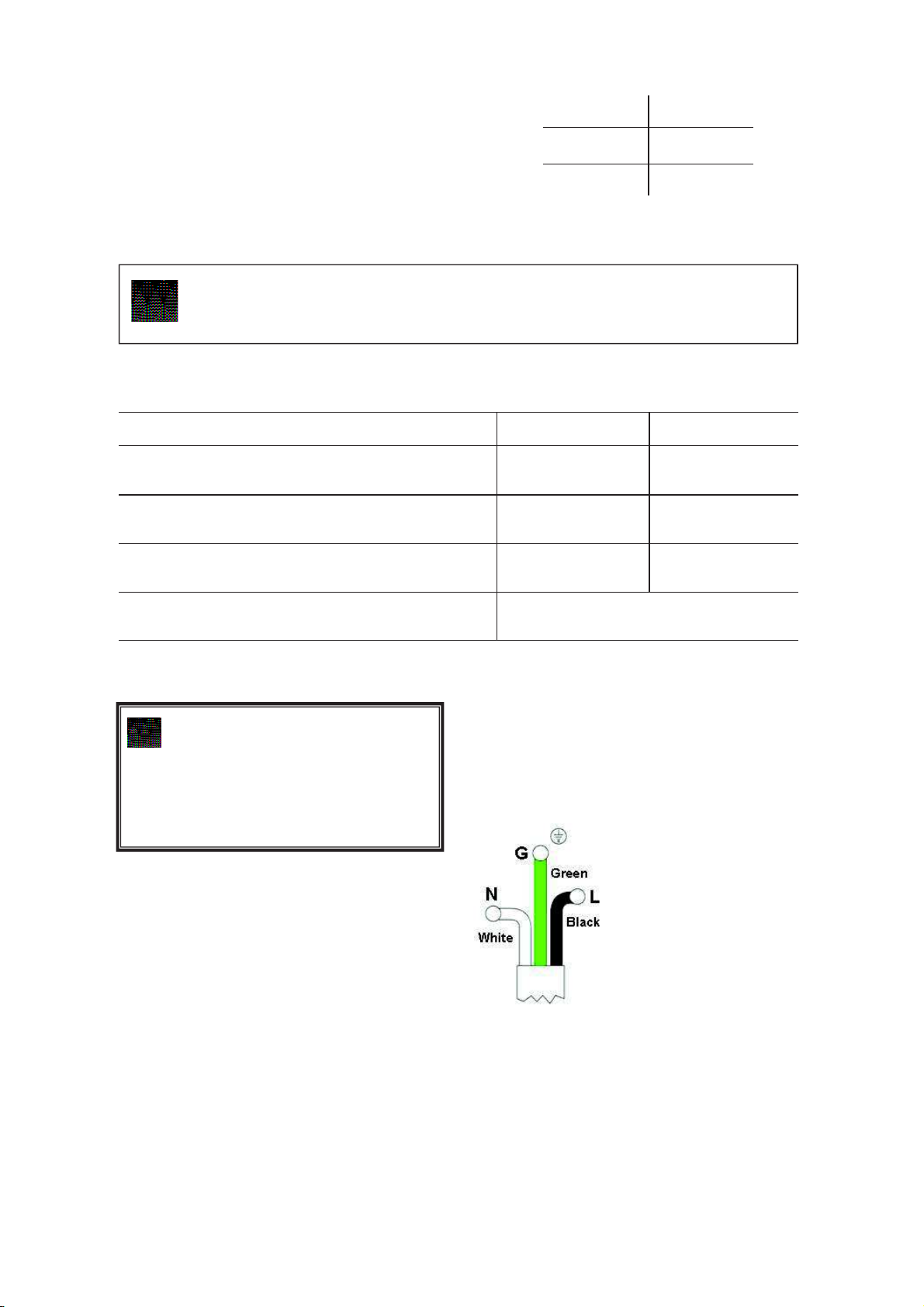

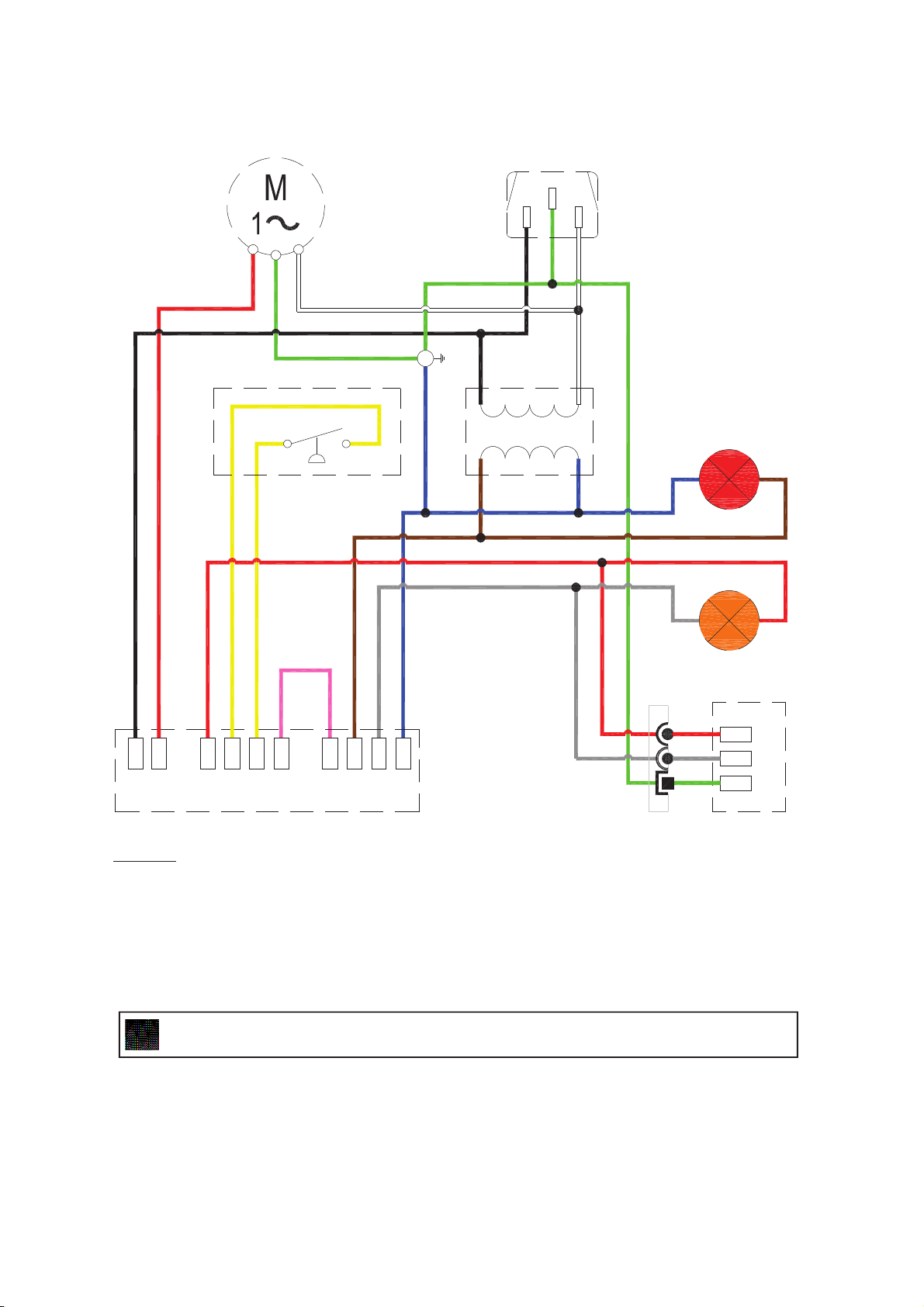

Whenever the heater is installed in locations

where airborne dust or other pollutants are

present, a fresh air supply should be ducted to

the burner.

A fresh air duct of 4”(101mm) dia. should be

installed from the fresh air to the air intake

connection on the fan housing. A flexible

jointing piece should be installed at the fan

connection with hose clamps to facilitate

expansion and contraction.

The maximum recommended length air duct is

25ft (7.6m) and the maximum number of elbows

is two. The minimum length is 18” (456mm).

The location of the fresh air duct inlet must be

where it will receive dust free clean air. An inlet

cap with bird screen must be fitted at the inlet of

the duct. If the duct inlet is located above the

roof the underside of the inlet terminal must be

at least 2ft (0.61m) above roof level and at least

10” (254mm) above any projection on the roof

within 7ft (2.1m) of the inlet. Intake pipe, fittings

and sealant are not furnished by the

manufacturer. Refer fig 7c & d.