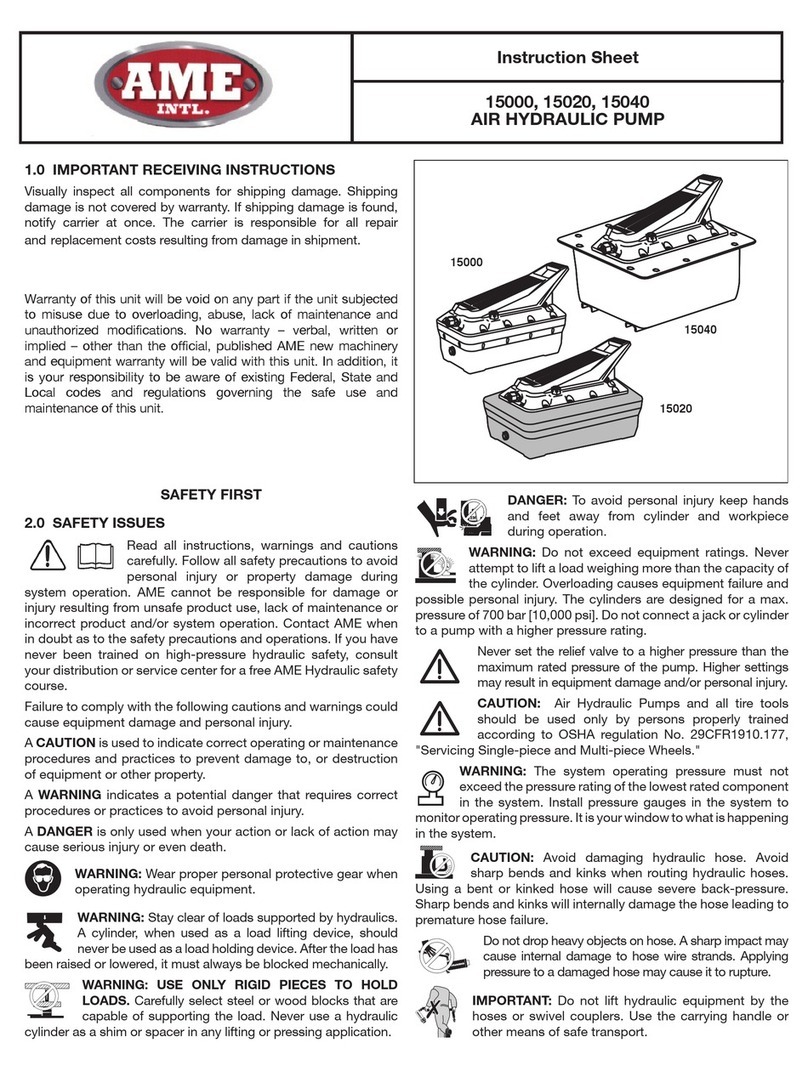

INSTRUCTION MANUAL

& PARTS BREAKDOWN

AME INTERNATIONAL - 2 -

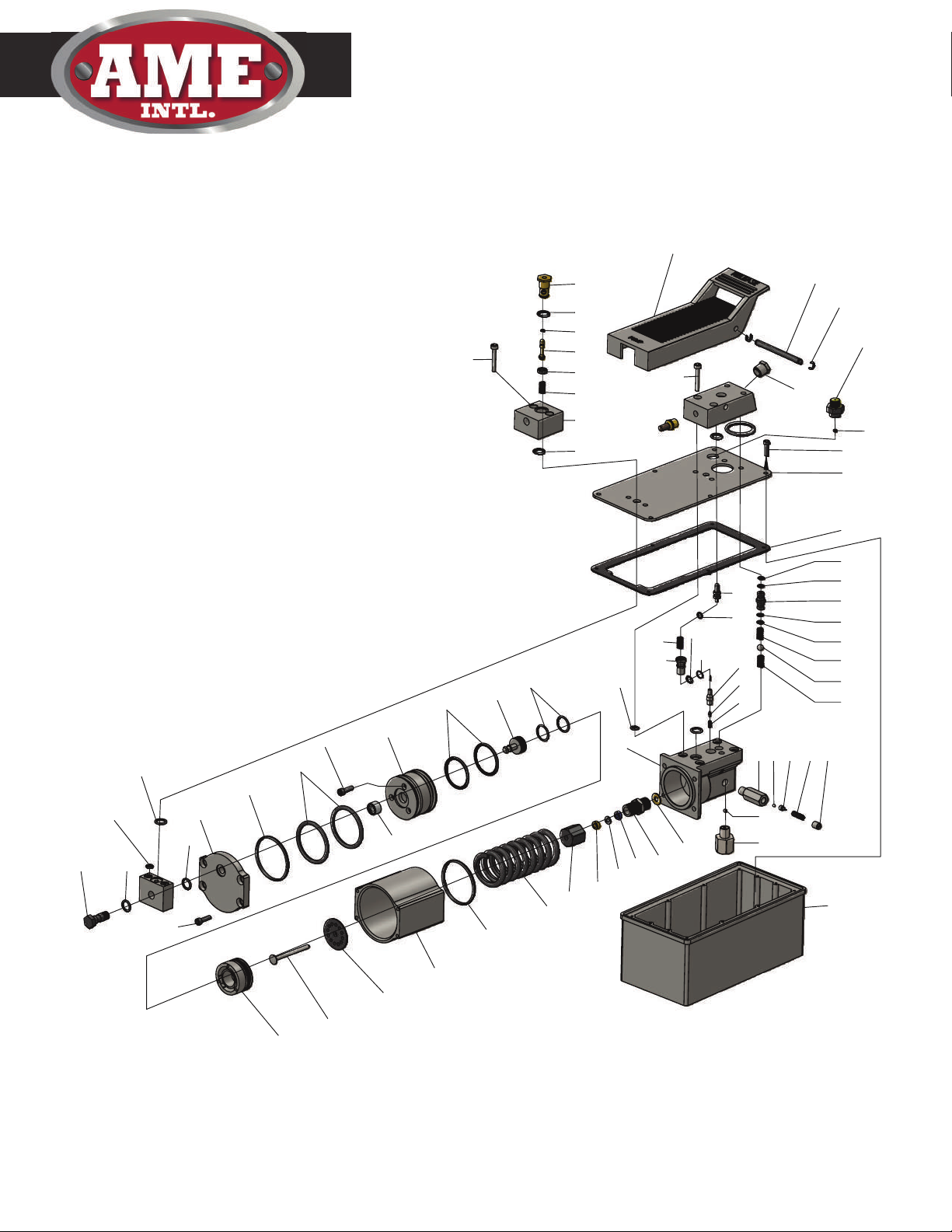

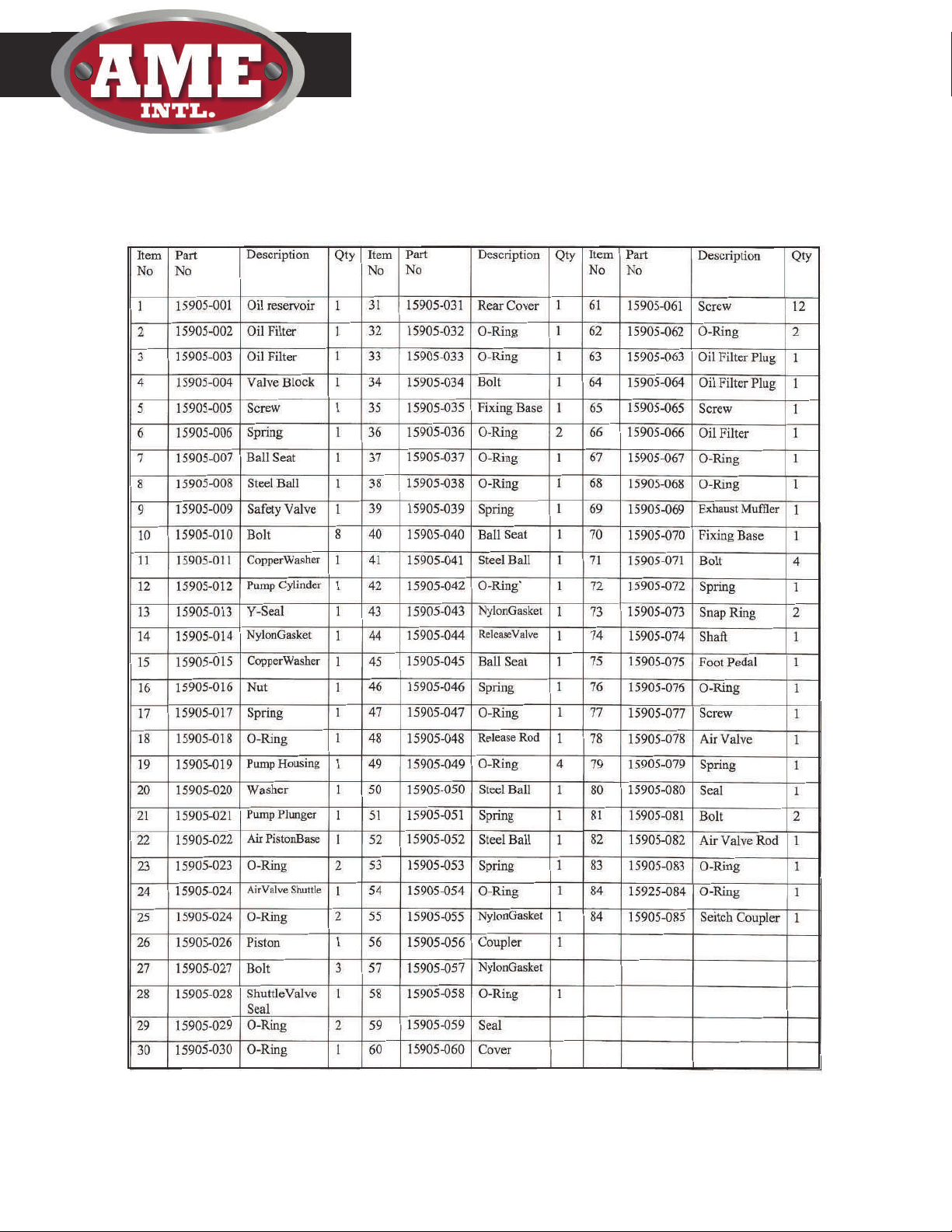

SPECIFICATION

DESCRIPTION

tools. It consists of an in-line air and hydraulic cylinder. The ratio of

100:1. In other words, 100 PSI out of every 1 PSI in – 100 PSI input

air pressure equals 10,000 PSI output pressure.

Depressing the RELEASE pedal causes a decrease in pressure and

BEFORE USE

To prevent oil leak during shipment, a metal knob is installed

and tightened to ensure the best sealing function. Loosen it

counterclockwise befo re use.

Note: Alwayssecure threadedport connectionswith non-hardeningpipethread

compound.Tightensecurelyto preventaccidentalremovalof componentswhilein

chart on above for details of oil port thread size, usable oil capacity, and more.

OPERATION

Operation of the unit is as follows:

1. Connect the hose of the Air/Hydraulic Pump to the hydraulic

coupling on the selected tool.

2. Connect the air supply line to the Air/Hydraulic Pimp. Air

supply should be 5-10 CFM at 100 PSI to obtain proper operating

characteristics. In addition, the air line should be equipped with an

3. Stepping on the PUMP end of the pedal engager the pump,

producing the fo rce necessary to run the tool.

4.

Depressing the RELEASEend of the pump pedal will release the

0UW\[(PY

7YLZZ\YL

WZP

0UW\[7VY[

;OYLHKZ

ë57;

6\[W\[7VY[

;OYLHKZ

57;

6PS+LSP]LY`

J\PUTPU

WZPWZP

0U[LYUHS

9LSPLM

:L[[PUN7ZP

<ZHISL6PS

*HWHJP[`

J\PU

>LPNO[

SIZ^MS\PK

3>/

¹_¹_¹

;OPZ(PY/`KYH\SPJ7\TWZ\WWSPLZO`KYH\SPJÅ\PKWYLZZ\YL[VZLSLJ[LK[VVSZ

0[ JVUZPZ[Z VM HU PUSPUL HPY HUK O`KYH\SPJ J`SPUKLY ;OL YH[PV VM O`KYH\SPJ

Å\PKWYLZZ\YLNLULYH[LKJVTWHYLK[VZ\WWS`HPYWYLZZ\YLPZ!0UV[OLY

^VYKZ7:0V\[VML]LY`7:0PU7:0PUW\[HPYWYLZZ\YLLX\HSZ

7:0V\[W\[WYLZZ\YL

+LWYLZZPUN [OL RELEASE WLKHS JH\ZLZ H KLJYLHZL PU WYLZZ\YL HUK

WYLZZPUN[OL7<47LUKVM[OLWLKHSWYV]PKLZÅ\PKWYLZZ\YL

;VWYL]LU[VPSSLHRK\YPUNZOPWTLU[HTL[HSRUVIPZPUZ[HSSLKHUK[PNO[LULK

[VLUZ\YL[OLILZ[ZLHSPUNM\UJ[PVU3VVZLUP[JV\U[LYJSVJR^PZLILMVYL\ZL

Note:(S^H`ZZLJ\YL[OYLHKLKWVY[JVUULJ[PVUZ^P[OUVUOHYKLUPUNWPWL

[OYLHK JVTWV\UK ;PNO[LU ZLJ\YLS` [V WYL]LU[ HJJPKLU[HS YLTV]HS VM

JVTWVULU[Z^OPSLPU\ZL;HRLJHYLUV[[VPU[YVK\JLJVTWV\UKPU[VWVY[

VYPÄJLZ-HTPSPHYPaL`V\YZLSM^P[O[OLZWLJPÄJH[PVUZHUKPSS\Z[YH[PVUZPU[OPZ

VWLYH[VY»Z THU\HS 2UV^ `V\Y W\TW P[Z SPTP[H[PVUZ HUK OV^ P[ VWLYH[LZ

ILMVYLH[[LTW[PUN[V\ZL9LMLY[VZWLJPÄJH[PVUJOHY[HIV]LMVYKL[HPSZVM

VPSWVY[[OYLHKZPaL\ZHISLVPSJHWHJP[`HUKTVYL

6WLYH[PVUVM\UP[PZHZMVSSV^Z!

*VUULJ[[OLOVZLVM[OL(PY/`KYH\SPJ7\TW[V[OLO`KYH\SPJJV\WSPUN

VU[OLZLSLJ[LK[VVS

*VUULJ[[OLHPYZ\WWS`SPUL[V[OL(PY/`KYH\SPJ7\TW(PYZ\WWS`ZOV\SK

IL*-4H[[OL7:0[VVI[HPUWYVWLYVWLYH[PUNJOHYHJ[LYPZ[PJZ

0UHKKP[PVU[OLHPYSPULZOV\SKILLX\PWWLK^P[OHUHPYSPULÄS[LY

:[LWWPUNVU[OL7<47LUKVM[OLWLKHSLUNHNLZ[OLW\TWWYVK\JPUN

MVYJLULJLZZHY`[VY\U[OL[VVS

+LWYLZZPUN [OL 9,3,(:, LUK VM [OL W\TW WLKHS ^PSS YLSLHZL [OL

WYLZZ\YL