INSTRUCTION MANUAL

& PARTS BREAKDOWN

AME INTERNATIONAL - 2 - WWW.AMEINTL.NET

AME INTERNATIONAL 2 WWW.AMEINTL.NET

15924 IN STR UCTION MA NUAL & PART LIST

5QT. AIR PUM P W/ STEEL RESER VO I R

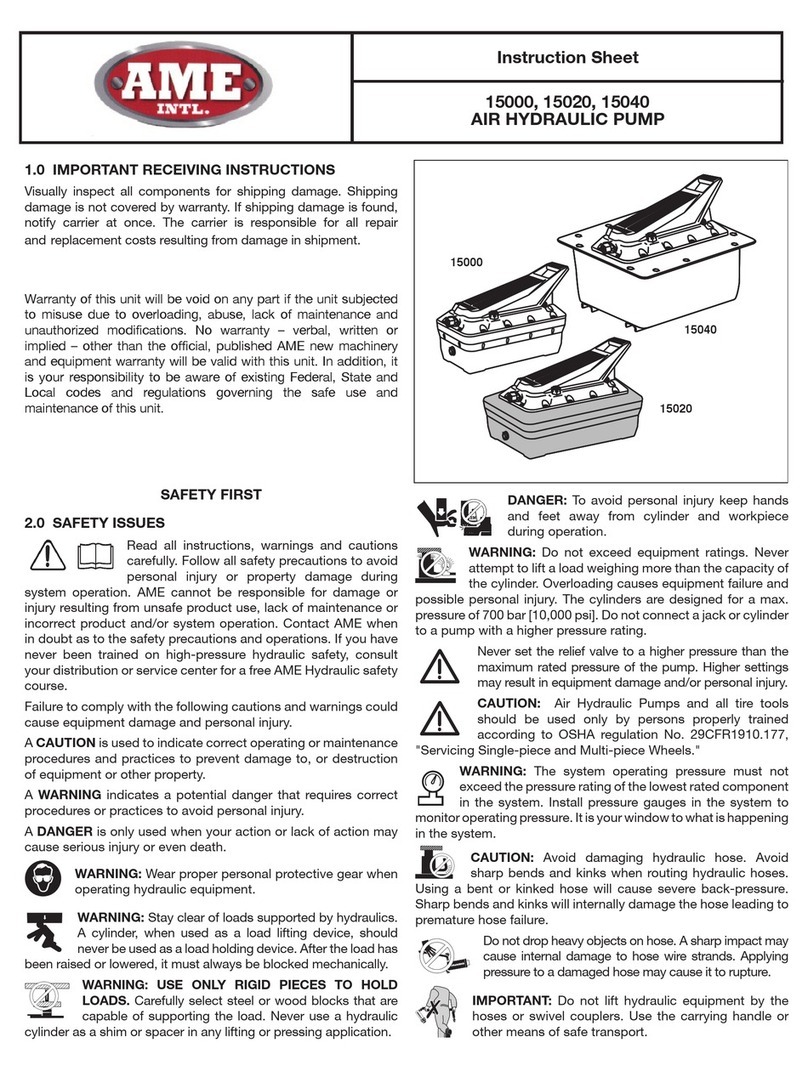

SPECIFICATION

DESCRIPTION

tools. It consists of an in-line air and hydraulic cylinder. The ratio of

100:1. In other words, 100 PSI out of every 1 PSI in – 100 PSI input

air pressure equals 10,000 PSI output pressure.

Depressing the RELEASE pedal causes a decrease in pressure and

BEFORE USE

To prevent oil leak during shipment, a metal knob is installed

and tightened to ensure the best sealing function. Loosen it

counterclockwise befo re use.

Note: Alwayssecure threadedport connectionswith non-hardeningpipe thread

compound.Tightensecurelyto preventaccidentalremovalof componentswhilein

chart on above for details of oil port thread size, usable oil capacity, and more.

OPERATION

Operation of the unit is as follows:

1. Connect the hose of the Air/Hydraulic Pump to the hydraulic

coupling on the selected tool.

2. Connect the air supply line to the Air/Hydraulic Pimp. Air

supply should be 5-10 CFM at 100 PSI to obtain proper operating

characteristics. In addition, the air line should be equipped with an

3. Stepping on the PUMP end of the pedal engager the pump,

producing the fo rce necessary to run the tool.

4.

Depressing the RELEASEend of the pump pedal will release the

Input Air

Pressure

(psi)

90-140

Input Port

Threads

¼-18 NPT

Output Port

Threads

3/8-18 NPT

Oil Delivery

(cu.in./min)

0 psi/10,000 psi

24.4/7.3

Internal

Relief

Setting (Psi)

10,000

Usable Oil

Capacity

(cu.in.)

140

Weight

(lbs. w/fluid

19

L+W+H

12.3”x6.7”x7.5”

This Air/Hydraulic Pump supplies hydraulic uid pressure to selected tools.

It consists of an in-line air and hydraulic cylinder. The ratio of hydraulic

uid pressure generated compared to supply air pressure is 100:1. In other

words, 100 PSI out of every 1 PSI in - 100 PSI input air pressure equals

10,000 PSI output pressure.

Depressing the RELEASE pedal causes a decrease in pressure and

pressing the PUMP end of the pedal provides uid pressure.

To prevent oil leak during shipment, a metal knob is installed and tightened

to ensure the best sealing function. Loosen it counterclockwise before use.

Note: Always secure threaded port connections with non-hardening pipe

thread compound. Tighten securely to prevent accidental removal of

components while in use. Take care not to introduce compound into port

orices. Familiarize yourself with the specications and illustrations in this

operator’s manual. Know your pump, its limitations and how it operates

before attempting to use. Refer to specication chart above for details of

oil port thread size, usable oil capacity, and more.

Operation of unit is as follows:

1. Connect the hose of the Air/Hydraulic Pump to the hydraulic coupling

on the selected tool.

2. Connect the air supply line to the Air/Hydraulic Pump. Air supply should

be 5-10 CFM at the 100 PSI to obtain proper operating characteristics.

In addition, the air line should be equipped with an air line lter.

3. Stepping on the PUMP end of the pedal engages the pump, producing

force necessary to run the tool.

4. Depressing the RELEASE end of the pump pedal will release the

pressure.