page 8

AK and 3K Series Installation and Service Instructions

4211-139-A 08-14-2009

The pressure relief valve must be

installed in such a fashion that the

risk of scalding is reduced to a

minimum. Draining the pressure

relief valve into the steam room may

present a scald hazard.

Boiling water may be discharged from

the drain. Proper precaution should

be taken too insure safety.

Draining the tank into the steam room

may present a scald hazard and/or

damage materials used to construct

the steam room.

Electrical shock hazard - Disconnect

all electrical power before servicing

the generator. All wiring should be

installed by a licensed electrical

contractor in accordance with local

and national codes.

The generator is designed for hookup

with copper wire only.

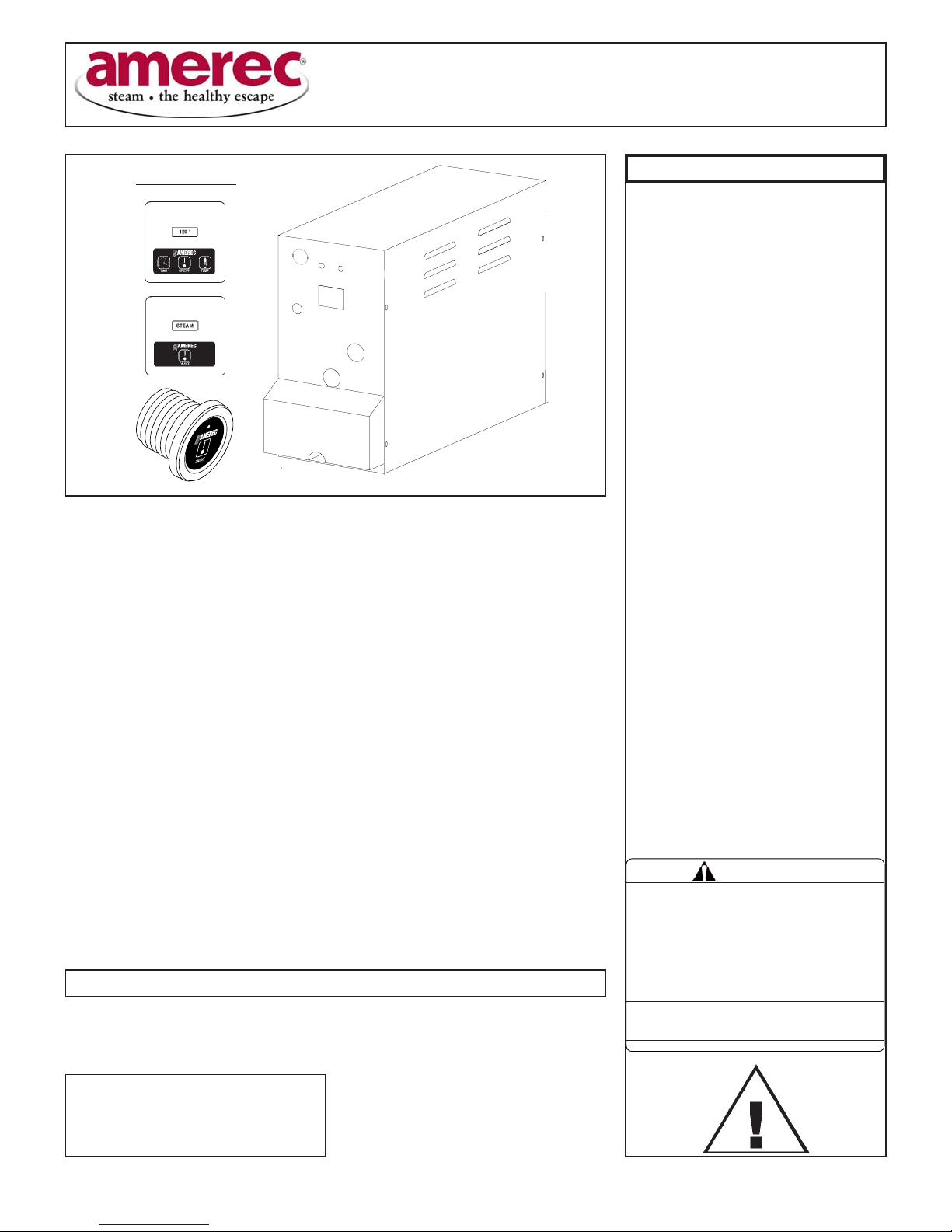

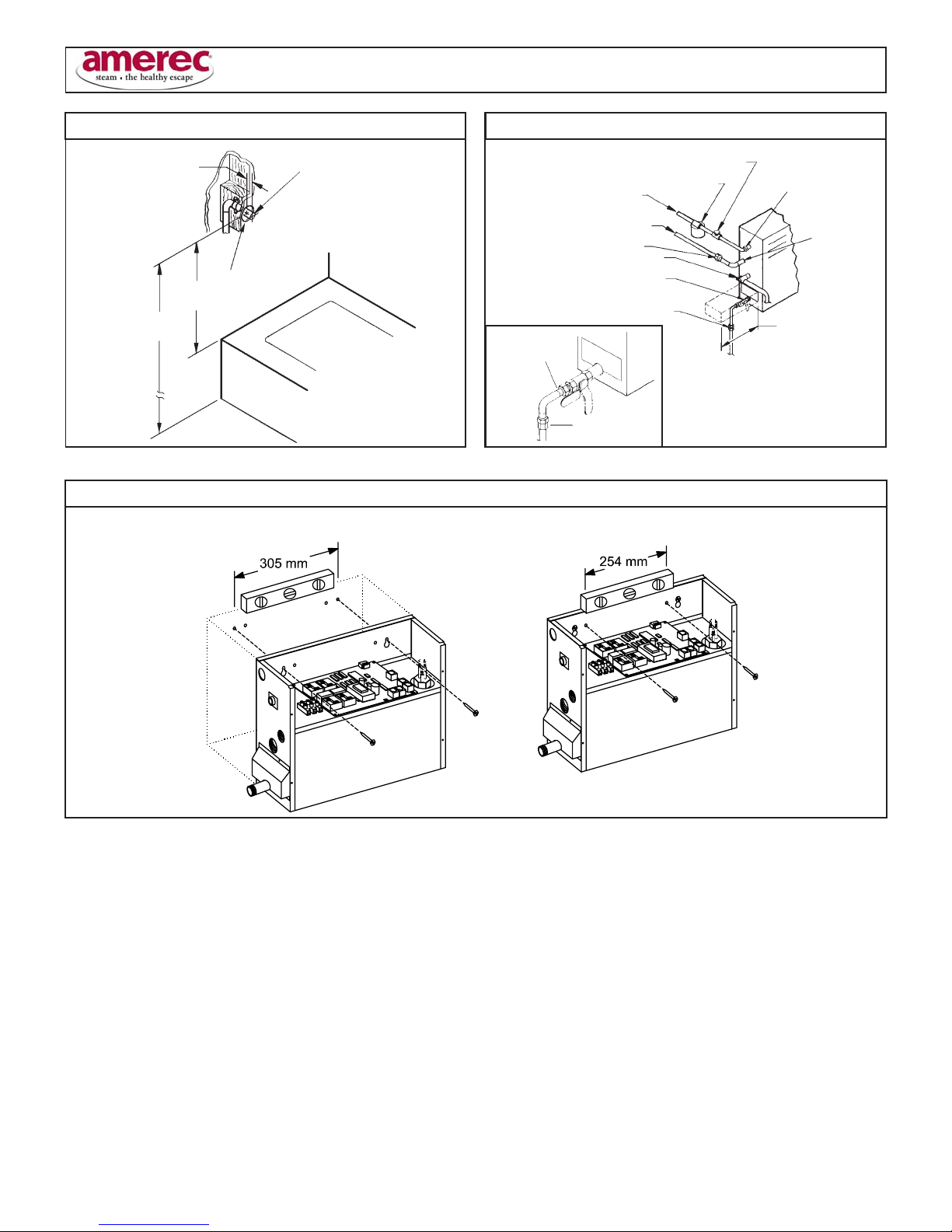

1. CONTROL CABLE ROUGH-IN

The low voltage control can be mounted up to 7,6 M

from the generator either inside or outside the steam

room for the K30, K60 or R30K control but with a built

in temperature sensor, the KT60 must be mounted

inside the steam room, also see #6 optional second-

ary generator control. String the 7,6 M cable from the

control location through 13 mm holes in the wall

studs or ceiling joists to the generator. Note: Do not

staple through or damage cable. Use factory supplied

cables only. Optional for tile rooms, a 2 gang rough-

in box may be installed at the desired control mount-

ing location. A mounting plate with proper diameter

hole is included with the control kit. Tile up to the hole

in mounting plate as indicated in diagram 13 or 14.

2. TEMPERATURE SENSOR CABLE ROUGH-IN

(REQUIRED FOR K60 OR K30 ONLY)

It is recommended that the sensor be mounted in the

steam room 150 mm from the ceiling, but not directly

over the steam dispersion head or more than 2,1 M

above the floor. String the sensor cable from the

sensor location through 13 mm holes in the wall

studs or ceiling joists to the generator location. Leave

305 mm of slack at the sensor location. Note: Do not

staple through or damage cable. Use factory supplied

cables only.

3. ELECTRICAL ROUGH-IN

Size wire for the generator as indicated by the Elec-

trical Information Chart on page 8. Use correct size

and type to meet electrical codes. Leave 1,2 M of

slack wire at generator location for finish hookup.

Connect the generator to a dedicated circuit breaker.

A GFI device is not required by UL. One may be

installed if required by local codes or the owner. A GFI

device will tend to nuisance trip due to heater element

aging.

4. ELECTRICAL FINISH

Materials (locally available):

- 3/4" Strain relief for supply wire.

A. Route the copper supply wire with appropriate

strain relief through the hole marked POWER ENTRY.

B. Connect the supply wires to terminals marked

230V and N (230V ~ Models) or L1,L2, L3, and N

(400V ~ 3N Models)

C. Connect the ground to the earth ground lug (

).

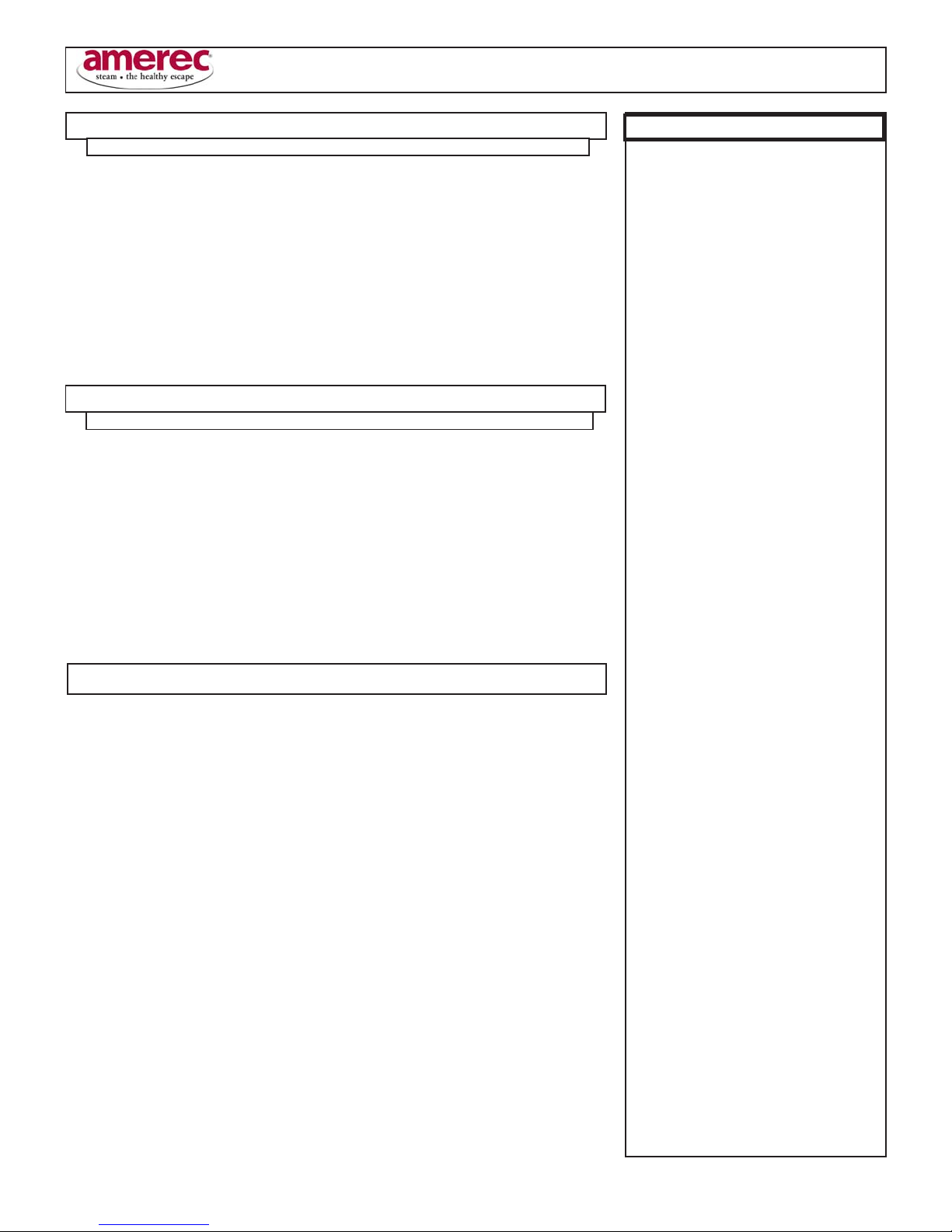

5. INSTALL GENERATOR CONTROL (K30,K60,KT60)

The low voltage controls can be mounted directly to

a finished wall either inside or outside the steam

room with the exception of the KT60 control which

must be mounted inside the steam room. Using a 50

mm hole saw, drill a hole in the finished wall where

the control is to be mounted (the control cable should

already be roughed-in to this location). With the

decorative cover removed from the control switch

assembly, insert the two control mounting screws

through the control housing (may need to punch

through skinned holes) and screw 0,6 mm into the

mounting bracket. Locate the control cable and plug

it into the back of the control housing. See diagram

8. Run a bead of 100% silicon caulk in-between the

2 ridges around the perimeter on the back of the

control housing. See diagram 9. Insert the mounting

bracket into the wall cavity by first pushing with the

control housing and then with a hard flat surface on

the control housing mounting screws which extend

out through the control face. Once the mounting

bracket has been inserted into the finished wall,

center the control and tighten the mounting screws

to draw the control housing securely against the

finished wall. Do not over tighten the mounting

screws. Install the decorative cover plate by sliding

the top of the cover plate over the tab on the top of the

control housing and pushing on the bottom of the

cover plate to complete the snap fit. See diagram 11.

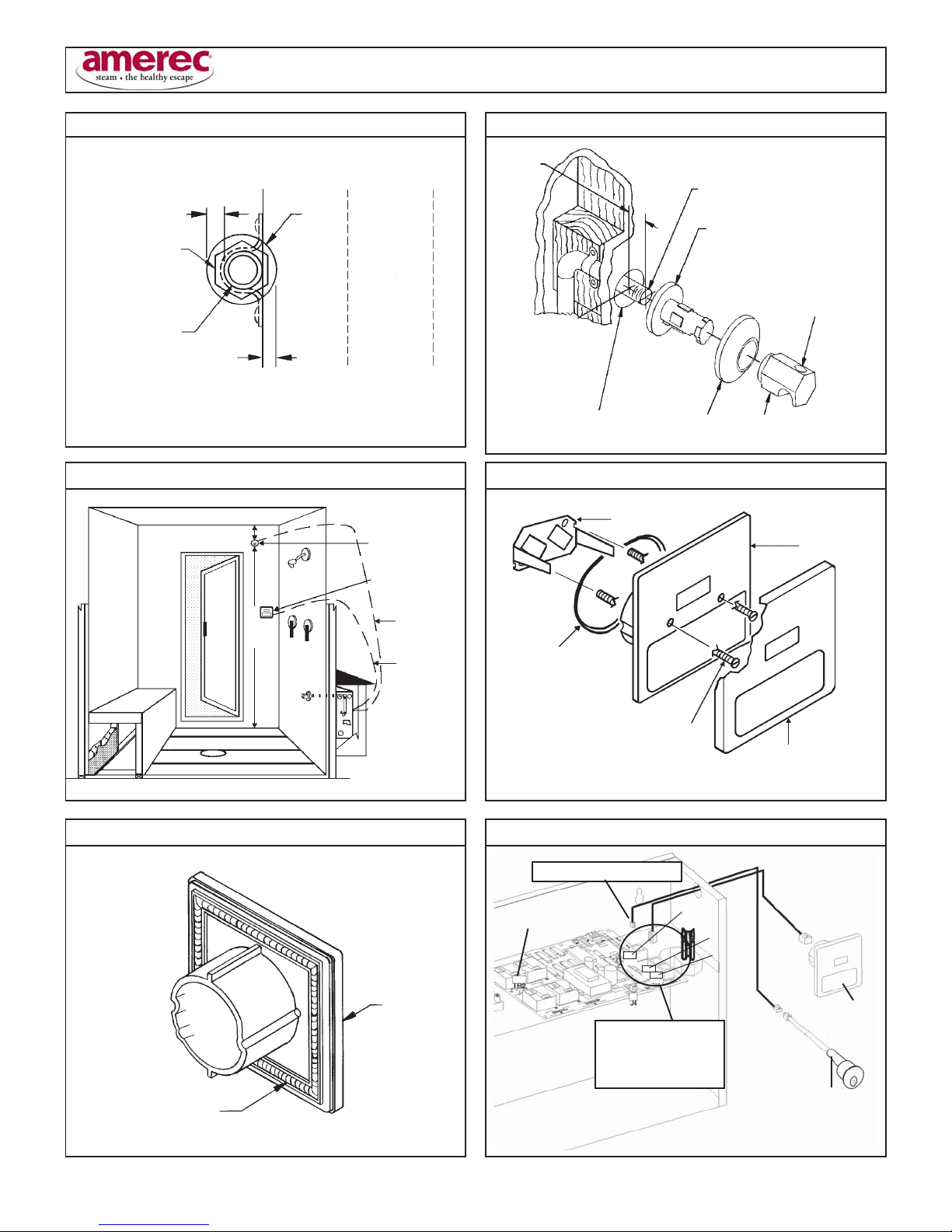

Route the generator end of the control cable through

the generator hole marked CONTROL WIRING EN-

TRY using the strain relief provided. Plug the control

cable into the connector on the printed circuit board

assembly. Insert cable into connector S30 if a K30

control is used or connector S60A if a K60 or KT60

control is used. See diagram 10.

5A. INSTALL GENERATOR CONTROL (R30K)

The low voltage control can be mounted directly to a

finished wall either inside or outside the steam room.

Using a 45 mm hole saw, drill a hole in the finished

wall where the control is to be mounted (the control

cable should already be roughed-in to this location).

Locate the control cable, pull it out through the

45 mm hole and plug the connector on the back of the

control housing. Run a bead of 100% silicone caulk

around the perimeter on the back of the control

housing. See diagram 13. Insert the control into the

wall cavity.

WARNING

SECTION 6: WIRING INSTRUCTIONS

SEE ELEC. INFO. CHART AND WIRING DIAGRAM