GENERAL INFORMATION:The AI Commercial Steam Generator is a low pressure heating boiler,

UL/CUL Listed, built to NEC requirements and with an ASME “H” stamped certified and National Board

registered pressure vessel.

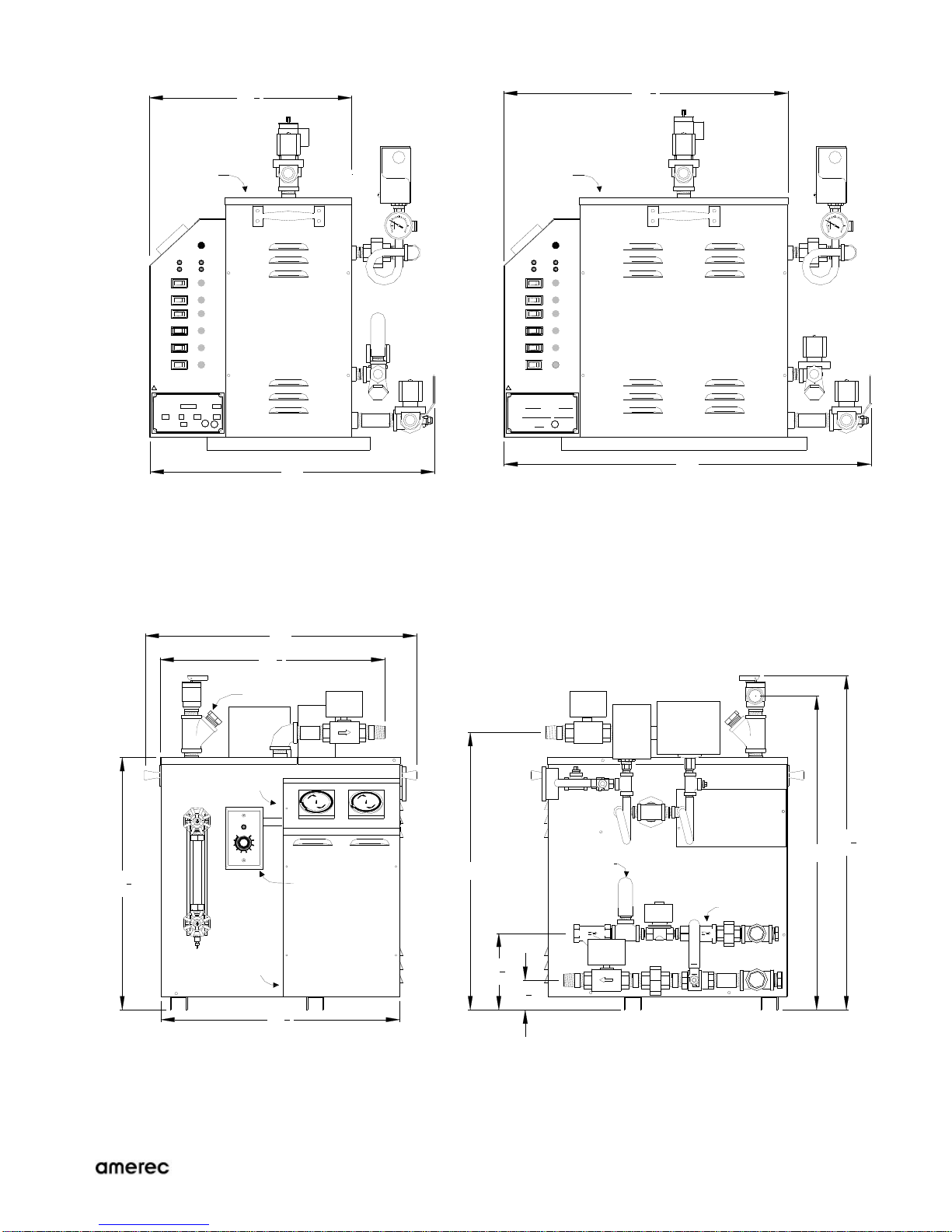

The generator has all steel construction with powder coated finish on visible surfaces and stainless steel

mounting feet to minimize the risk of corrosion. The mounting feet hold the generator one inch above the floor to

allow cleaning the floor below it and to further prevent corrosion. This also allows the generator to sit directly on

a combustible surface without additional protection. The feet extend beyond the sides of the generator chassis

and have clearance holes to allow securing the generator in place using ¼” bolts.

AI Commercial Steam Generators are factory assembled and tested and ready to install. All generators are

plumbed for a ½” potable water feed inlet, a ¾” drain discharge and a ¾” pressure relief valve discharge.

Generators are available for connection to 208VAC or 240VAC single or three phase, or 480VAC in three phase

only. All models require the appropriate full power electrical service plus ground. Models in 208V and 240V also

require a 14 gauge minimum Neutral for the control circuit; 480V models require a separate 120VAC+N service

for the control circuit. Use 75° minimum copper wire for all service connections. A ¾”-1”-1½”-2”

combination knockout is provided in the generator’s electrical box for the main service conduit and an additional

½”-¾” knockout is provided for the 480V models’ 120V control service.

The generator’s control circuit is protected by a 250VAC 3A non-time-delay fuse installed in the front panel of the

generator’s electrical box. A 100mA time-delay fuse mounted on the generator’s circuit board protects the

board’s low voltage circuitry. No other fusing is installed in the steam generator.

Room controls (ON/OFF, thermostat, temperature sensing and steam Refresh™) are connected during generator

installation using factory supplied wire or cables. Room controls operate on a low voltage Class 2 circuit. An

access hole and knockouts, ½” trade size, are provided for room control wiring. The thermostat must be

mounted outside the steam room, the temperature sensor must be mounted inside the steam room, the optional

Refresh™ switch mounts inside the steam room, the optional I60 Bath On/Off switch is available for mounting

outside the steam room. Temperature sensors require factory supplied cables for connection to the generator,

all other controls require 3 conductors, 18 to 24 AWG copper, 75° 300V minimum (25 foot long cables are

provided).

Standard equipment:

Manual operation (generator mounted RUN switch and manual ball valve drain) and single steam room (one

steam valve, one temperature sensor, one thermostat with integral steam bath ON/OFF switch and bath-on

indicator light, two steam heads). Switches allowing manual heat and water control during routine service,

lights indicating heat and valve operating status and self-check fault codes.

Optional equipment:

Second steam room (second steam valve, thermostat and temperature sensor) factory installed only!

RUN CLOCK (7-day or 24 hour clock or 7-day programmable digital clock for generator ON/OFF scheduling).

CoolFlush™ Auto Drain (24 hour clock plus electronic drain valve).

Steam bath

ON/OFF switch: commercial (mounts to single gang switch box in a dry location only, automatic

timeout 60 minute bath time, integral bath-on indicator light).

Steam bath

ON/OFF switch: residential (membrane switch, may be mounted in steam room, automatic

timeout 60 minute bath time, integral bath-on indicator light).

Steam Refresh™ (membrane switch for mounting inside steam room, status indicator light).

Manual reset low water cut-off (check your local codes for requirements)

Water Quality Requirements:

The nature of a steambath generator requires testing of the feedwater to avoid potential high concentrations of

impurities which can cause a deposit or scale to form on the internal surfaces. This deposit or scale can interfere

with the equipments proper operation and even cause premature generator failure. Concentration of impurities is

generally controlled by treating the feedwater and/or “blowing down” the generator when it is not heating. The

“blow down” process involves removing a portion of the tank water with high solid concentration and replacing it

with makeup water.