3

new owner in order to facilitate the sending of any

additional parts to be integrated into the manual.

d) For further information or clarifications, it is possible to

contact the Assistance Service (see section 13.2)

The Manufacturer declines all responsibility in the event of the following:

■Incorrect use of the machine

» Use of the machine by untrained personnel

» Any use of the machine that contravenes that which is stated in this manual

-Any use of the machine that contravenes the laws and standards in force

» Any use with defect of primary alimentation

■Exceeded of limits service

-Excessive mechanicals stress

The user is required to guarantee that:

■All operations for transport, connection, use, maintenance and repair will be carried out by qualified

personnel

■Qualified personnel are understood to be (as per IEC 364} persons who, in terms of their training,

experience, knowledge of standards, prescriptions, accident prevention provisions and conditions of use

and service, are able to cany out all necessary interventions and to recognise and avoid all possible

danger and/or damage.

" These persons will avail of all of the relevant information and training required, including any local

prescriptions, to which they will adhere when carrying out any operations,

■Unqualified personnel will be prohibited from carrying out any operation even directly on the machine

or equipment.

■During the stages of installation, any local or special prescriptions and/or in any case, all prevention

conditions that have not been discharged will be met using additional safeguards.

MARKING DATA AND DELIVERY CHECKS

Ensure that the equipment shows no signs of damage and that no parts are missing. In the event of damage,

contact the relevant insurance company or the Manufacturer. In the event that the supplied goods are

incomplete, contact the Manufacturer directly. Each machine has an identification plate.

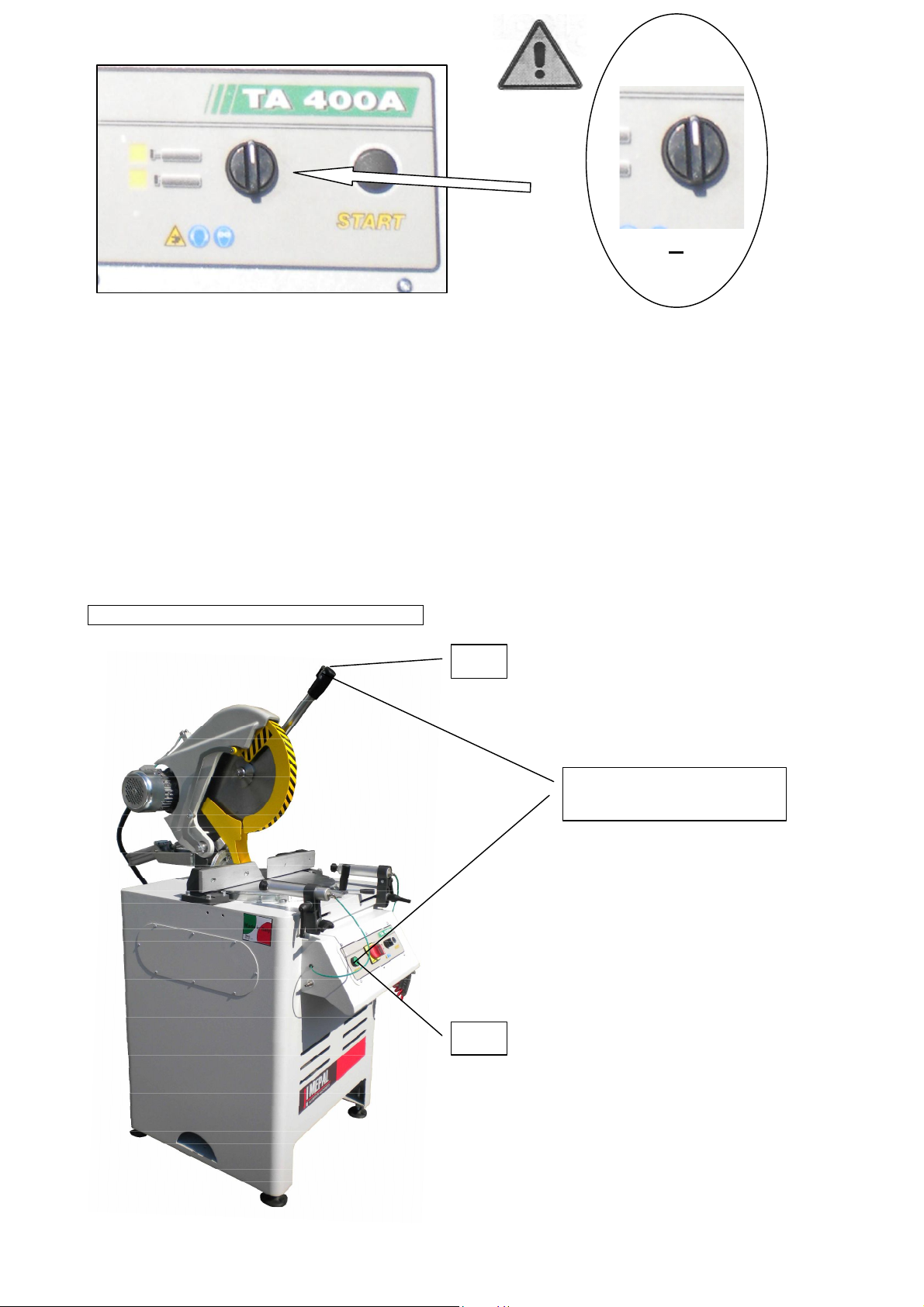

MACHINE IDENTIFICATION PLATE

This plate contains information about the Manufacturer as well as the

model and progressive serial number of the machine. For any

communication.regarding the machine (problems, interventions under

guarantee, replacement parts, etc.) always refer to this plate and to the

information it contains.

The CE marking on the machine means that it conforms to the European Community Directives with regard to Health

and Safety in the workplace.

3.1 HANDLING

Machines are delivered in a protective plastic covering or packed on pallets with crates - wooden crates

cardboard coverings, according to the requirement stated at the time of order.