EN

ENGLISH

-2- FORM NO. 70255B Clarke®American Sanders Operator's Manual (EN) - Floorcrafter

Table of Contents

Operator Safety Instructions........................................................................................................ 3

Introduction and Machine Specifications..................................................................................... 5

230V Electrical Connection Instructions...................................................................................... 6

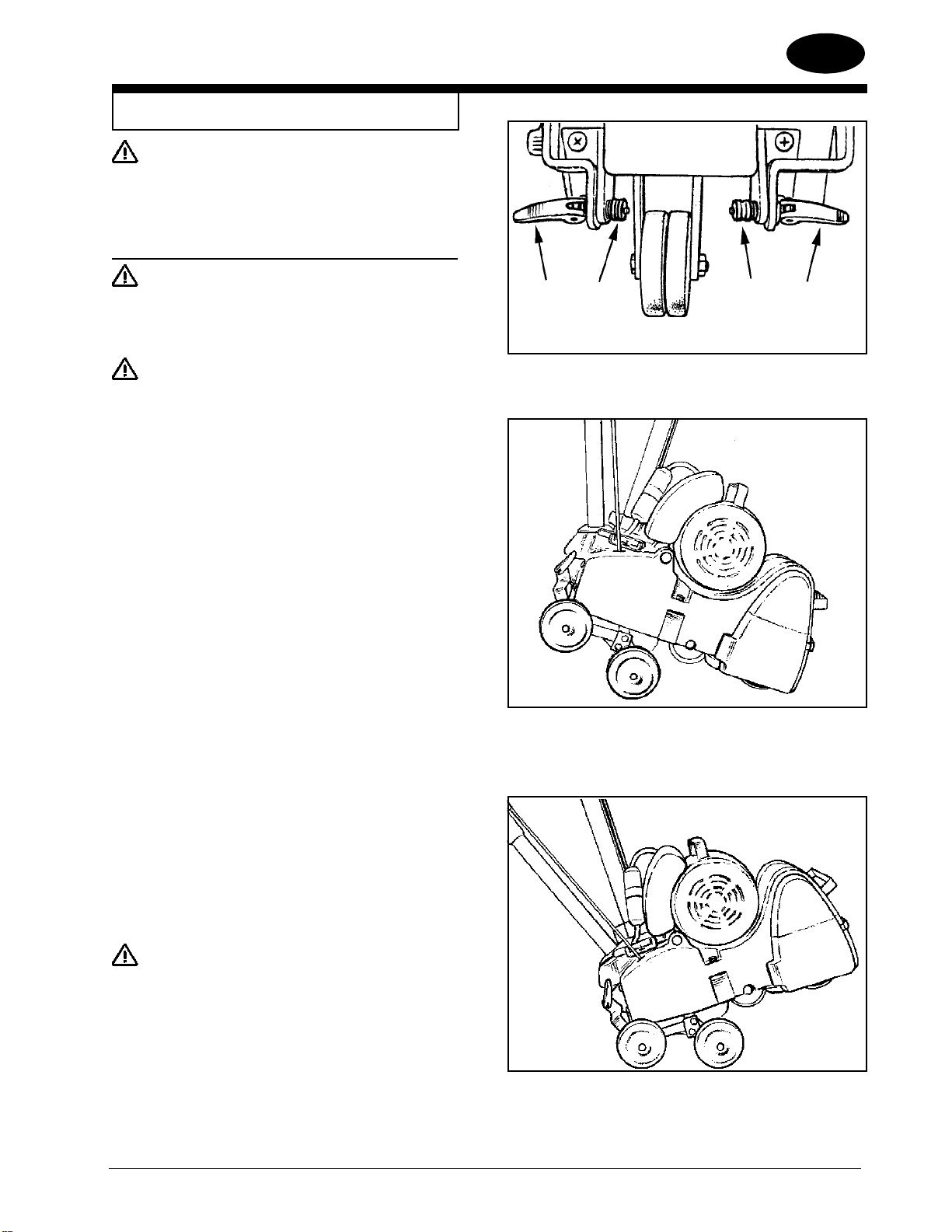

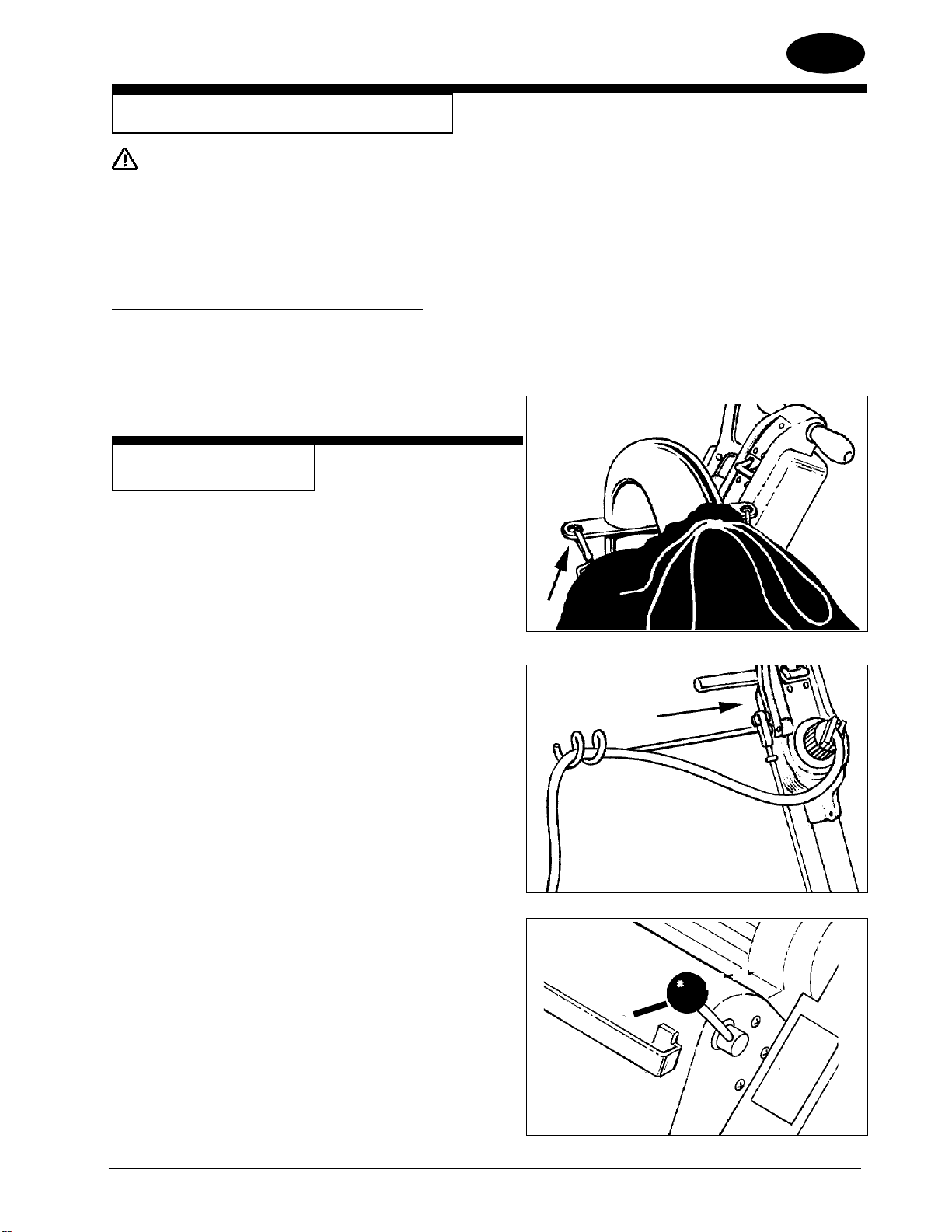

How to Transport the Machine..................................................................................................... 7

One Person............................................................................................................................ 8

Two People ............................................................................................................................ 9

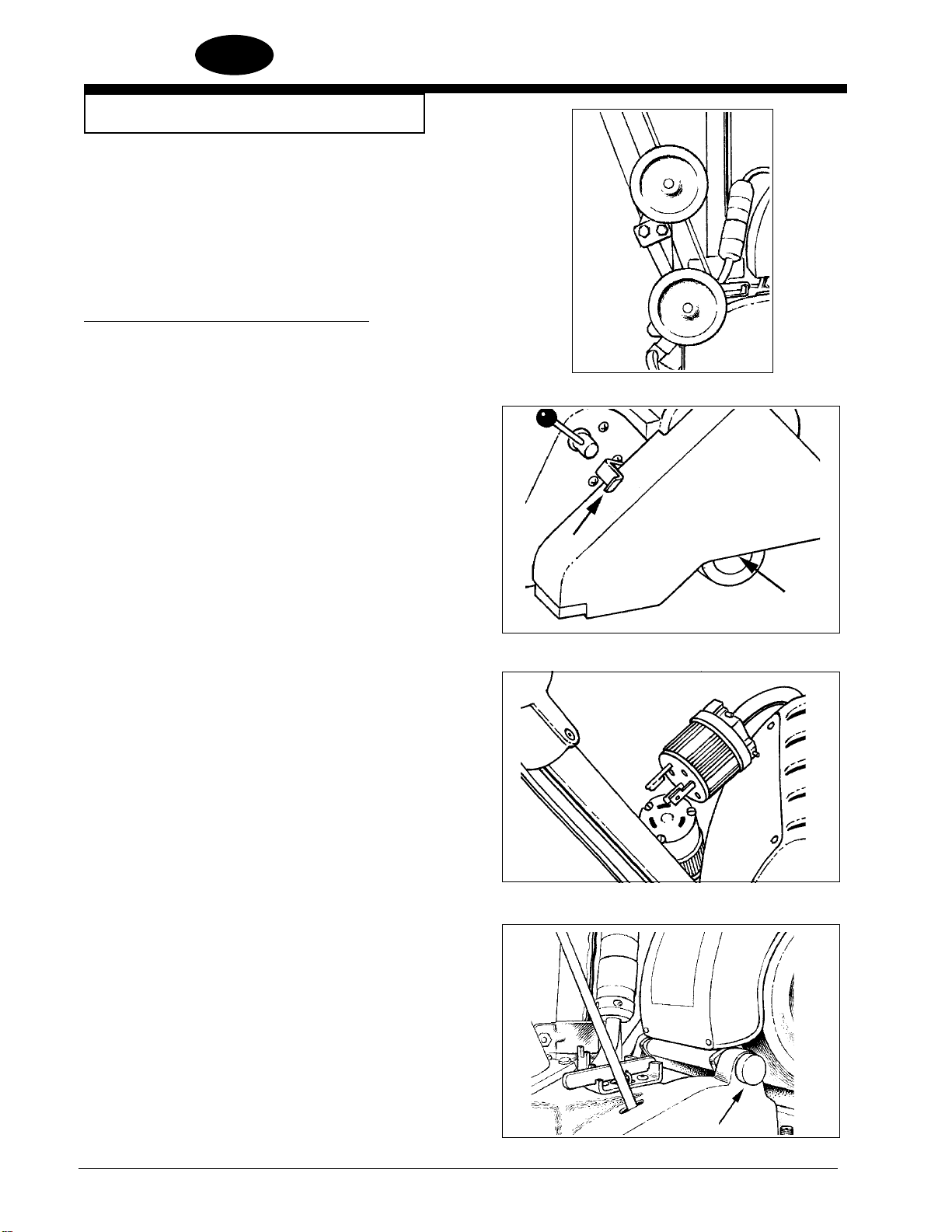

Machine Set-Up........................................................................................................................... 9

How to Operate the Machine......................................................................................................11

Sanding Cuts and Sandpaper ................................................................................................... 13

Chatter Wave Prevention .......................................................................................................... 14

Sander Adjustment Procedures................................................................................................. 15

Dust Shoe.............................................................................................................................. 15

Sanding Pressure.................................................................................................................. 15

Leveling the Drum ................................................................................................................ 15

Belt Tracking.......................................................................................................................... 16

Operating Control .................................................................................................................. 16

Routine Maintenance................................................................................................................. 17

Sanding Chamber.................................................................................................................. 17

Wheels................................................................................................................................... 17

Dust Bag................................................................................................................................ 17

Drive Belt............................................................................................................................... 17

Bearings ................................................................................................................................ 18

Rollers ................................................................................................................................... 18

Troubleshooting......................................................................................................................... 19

SECTION II Parts and Service Manual

Main Assembly Drawing #1.......................................................................................................62

Main Assembly Parts List #1................................................................................................ 63

Handle Control Assembly Drawing #2...................................................................................... 64

Handle Control Assembly Parts #2....................................................................................... 65

Contact Wheel & Truck Assembly Drawing #3 .......................................................................... 66

Contact Wheel & Truck Assembly Parts List #3................................................................... 67

Belt Tensioner Assembly Drawing #4 ........................................................................................ 68

Belt Tensioner Assembly Parts List #4 ................................................................................. 69

Dolly Assembly Drawing & Parts List #5.................................................................................... 70

Motor Assembly & Parts List #6.................................................................................................71

Wiring Diagram.......................................................................................................................... 72

WARNING!

The Products sold with this Manual contain or may contain chemicals that are known to certain governments (such as the State of

California, as identified in its Proposition 65 Regulatory Warning Law) to cause cancer, birth defects or other reproductive harm. In

certain locations (including the State of California) purchasers of these Products that place them in service at an employment job site or

a publicly accessible space are required by regulation to make certain notices, warnings or disclosures regarding the chemicals that are

or may be contained in the Products at or about such work sites. It is the purchaser’s responsibility to know the content of, and to comply

with, any laws and regulations relating to the use of these Products in such environments. The Manufacturer disclaims any responsibility

to advise purchasers of any specific requirements that may be applicable to the use of the Products in such environments.