Superabrasive User Manual Original Language Lavina®21-X 4/2015

4

TABLE OF CONTENTS

WARRANTY AND RETURNS................................... 3

1. GENERAL INFORMATION ...................................... 5

Manufacturer............................................................. 5

General Description .................................................. 5

Machine characteristics............................................. 5

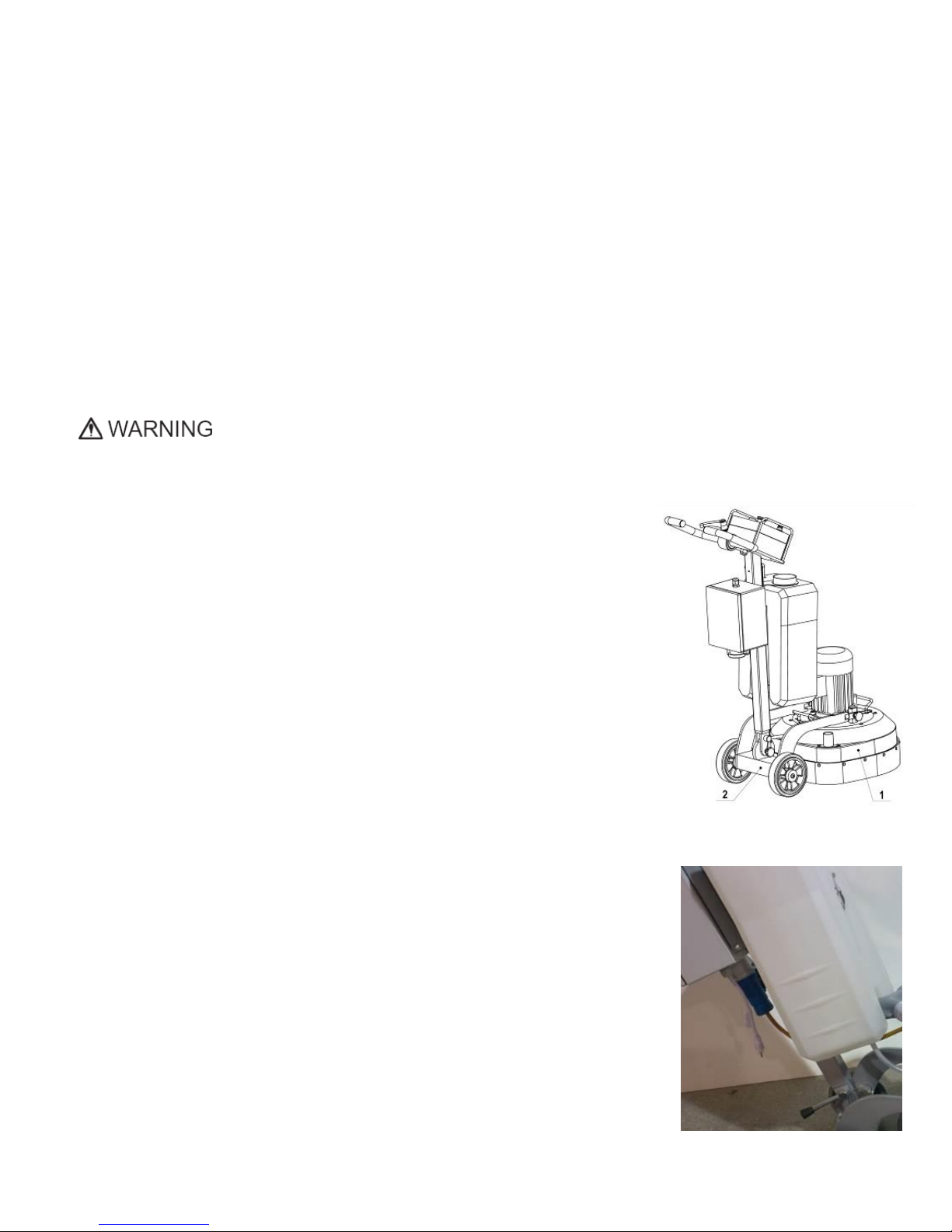

Lavina 21 Main design.............................................. 5

ENVIRONMENTAL CONDITIONS ........................... 5

Electrical Connection ................................................ 5

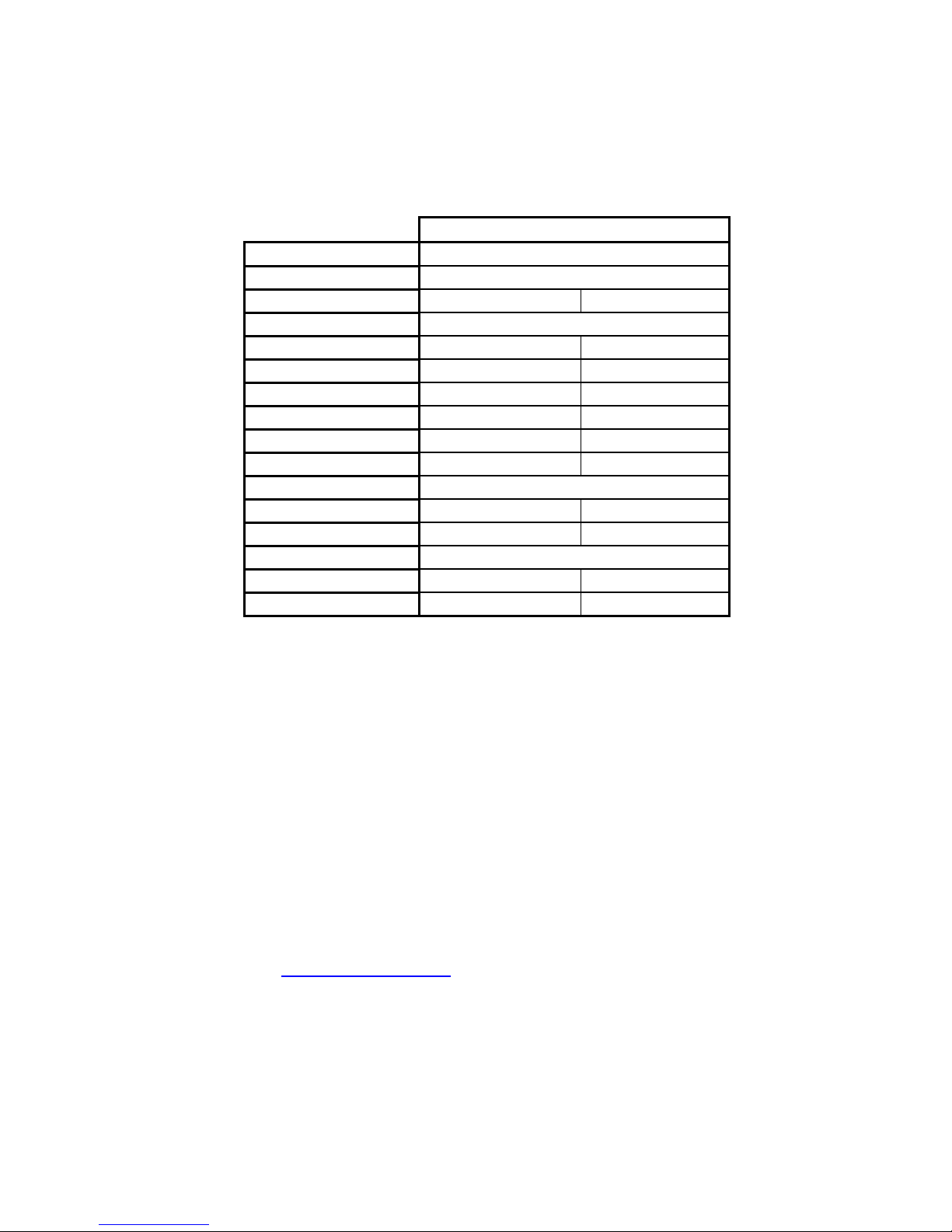

Vacuum Connection.................................................. 6

Technical Data .......................................................... 6

Vibrations .................................................................. 6

Sonorous Emissions ................................................. 6

Label Data................................................................. 6

Customer Service...................................................... 6

2. SAFETY INSTRUCTIONS........................................ 7

Recommended Use ............................................. 7

Prohibited Use........................................................... 7

Preparation for work.................................................. 7

protection Devices ................................................ 7

Arrest Functions ................................................... 7

Safe Use.................................................................... 7

Residual Risks .......................................................... 7

Before You Begin...................................................... 7

Operating Machine.................................................... 7

After Work is completed............................................ 7

The Work Area.......................................................... 7

PERSONAL PROTECTIVE Equipment (ppe)....... 7

Operator.................................................................... 8

3. HANDLING AND TRANSPORTATION .................... 8

Adjusting the column angle....................................... 8

Adjusting the handle.................................................. 8

Preparing the machine for transportation.................. 9

Storage...................................................................... 9

4. OPERATION............................................................. 9

Preliminary Controls.................................................. 9

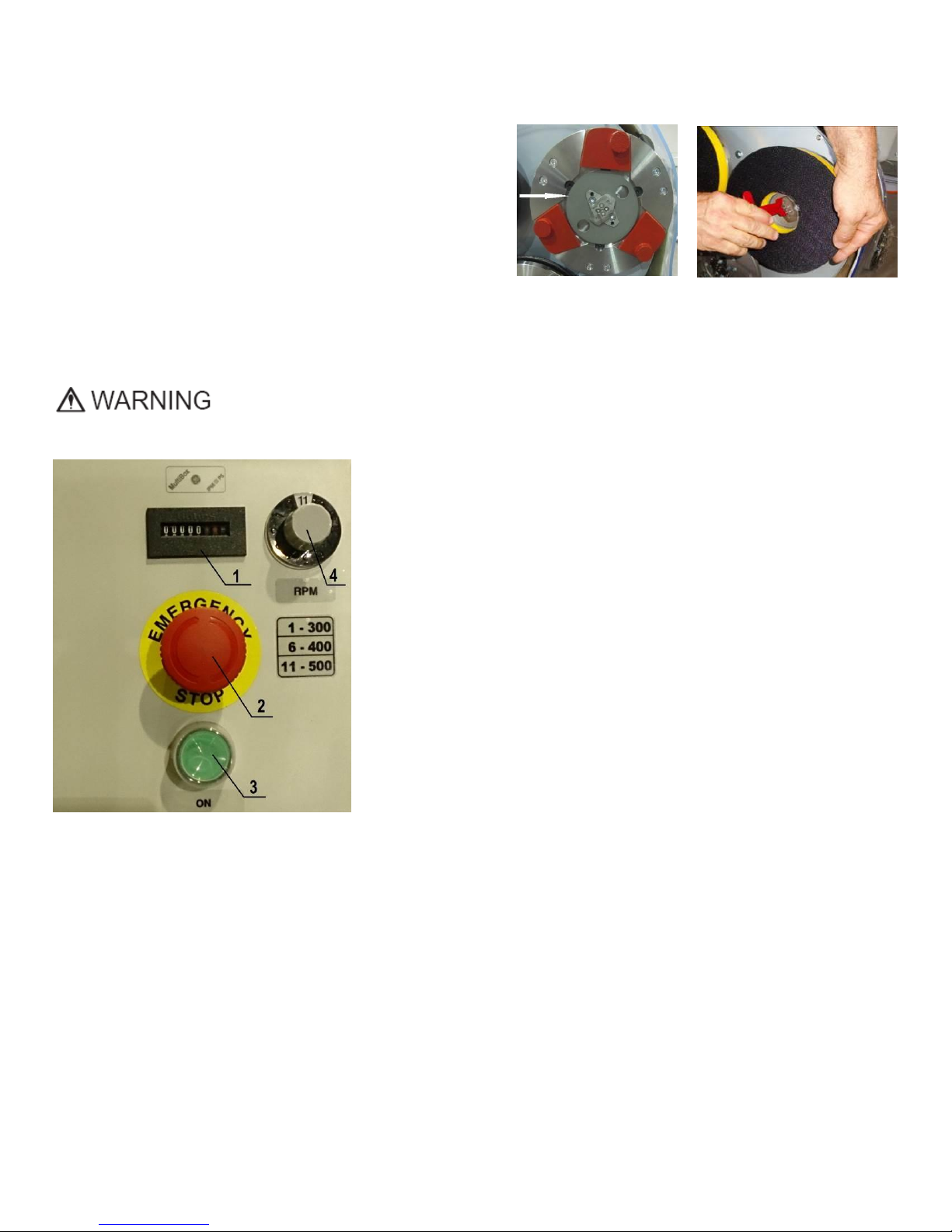

ADJUSTING AND MOUNTING TOOLS................... 9

Plug and cable ........................................................ 10

Control Board.......................................................... 10

Starting the Machine ............................................... 10

Operating the Machine............................................ 10

Stopping the Machine ............................................. 11

5. TOOLS AND ACCESSORIES ................................11

Weights....................................................................11

Tool holder key ........................................................11

Foam Plate...............................................................11

Security plate for Quickchange pads.......................11

6. POPULAR TOOLS..................................................12

RECOMMENDED TOOLS.......................................12

7. MAINTENANCE AND INSPECTION ......................13

Cleaning...................................................................13

Check Daily..............................................................13

Check and replace Every 200 Working Hours.........13

Check and replace Every 400 Working Hours.........13

Vacuum....................................................................13

Water Leaks.............................................................13

Mechanical Parts .....................................................13

ELECTRICAL SYSTEM...........................................13

ELECTRICAL SCHEME..........................................14

8. TROUBLESHOOTING............................................15

Index of problems and Solutions .............................15

8.1 Replacing power cord and plugs .......................15

8.2 DISMOUNTING AND MOUNTING TOOL

HOLDER TO CHANGING V-RINGS AND FELT-

RINGS......................................................................15

8.3 DISASSEMBLING AND MOUNTING TOOL

HOLDER TO CHANGE BUFFERS AND ELASTIC

ELEMENT................................................................15

8.4 Tensioning used planetary Belt .........................17

8.5 Mounting and tensioning a new planetary belt..18

8.6 TENSIONING AND REPLACING THE Main

BELT........................................................................18

8.7 REPLACING THE PULLEY UNITS...................19

8.8 Motor Connection ..............................................20

9. SPARE PARTS .......................................................20

1. LAVINA®21-X General Parts ....................................21

2. LAVINA®21-X Top cover parts 1...............................21

4. LAVINA®21-X top cover Parts 2 ...............................22

3. LAVINA®21-x Guard parts .......................................22

5. LAVINA®21-X Planetary drive Parts .........................22

6. LAVINA®21-x bottom cover Parts ...........................23

7. LAVINA®21-x TRANSMISSION BELT PARTS ...............24

8. LAVINA®21-x PULLEY UNIT PARTS...Error! Bookmark

not defined.

9. LAVINA® 21-X Tool Holder Parts ..............................26

/see also fig.8.3.12/ ...................................................26

10. LAVINA®21-X CARRIAGE PARTS .............................26

11. LAVINA®21-X ELECTRICAL PARTS ...........................28