Amico Falcon IT Guide

Quick Setup

Falcon IT (FIT)

Installation and Adjustment Instructions

Amico Accessories | www.amico.com

85 Fulton Way, Richmond Hill

Ontario, L4B 2N4, Canada

Toll Free Tel: 1.877.264.2697 l Tel: 905.763.7778

Fax: 905.763.8587

FIT

1 Swivel Post

For mounting and positioning of monitor

2 Extension Arm

extension arm to increase movement range of AHM (if applicable)

3 Mounting Adapter

Dierent mounting adapters will be provided based on the rail system

used

4 Cable Management

Manage cables for the FIT Station for a clutter free environment

5 Height Locking Lever

Locks arm at desired height

6 Counter Balance Bolt

Balance the weight of the monitor on the AHM arm of the FIT station

7 Negative Tilt Knob

Tilts the keyboard tray’s back downwards for proper ergonomics in

certain cases

8 Keyboard Tray (2 x mousepad, 12 x dual lock coins provided; wrist rest if purchased)

Location for Keyboard & Mouse

9 Rail System

For mounting the FIT station, varies depending on user’s selection. Rail

is packed separately and must be installed rst

10 VESA Head

For mounting the monitor

11 Mouse/Scanner Holder

For storing mouse and hand-held scanners

Installation Tools & Reference

Medical Facility Responsibility

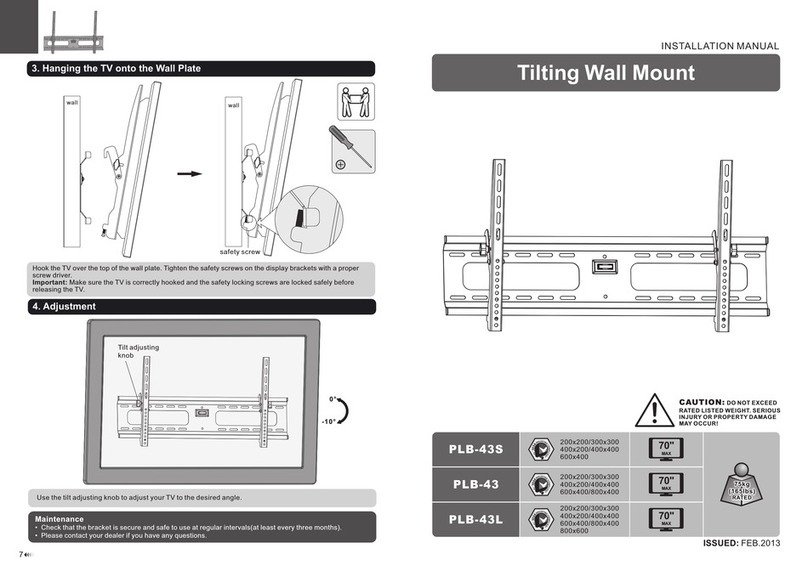

2. Installation to Monitor

It is the responsibility of the end user to ensure all aspects of the installation are covered by following the full manual at:

http://www.amico.com/les/product/les/acc_im_falcon_it_station.pdf

1. Installation to Structure

Mounting on an MRS Rail

4 x 1/4-20 Set screws

Use 1/8” (3mm) hex key

to tighten

Figure 1 Figure 2

1. Determine the monitor mounting conguration. VESA 75 (75 mm x 75 mm M4 thread) or

VESA 100 (100 mm x 100 mm M4 threads).

2. VESA 100 conguration: 2 screws are partially threaded into the top 2 holes in the back

of the monitor. The monitor can then be hung up on the VESA Head through the two slots

at the top. Insert 2 more screws through the VESA-100 mounting holes at the bottom and

tighten all screws (Figure 1).

3. VESA-75 conguration: Rotate the VESA Head so the 2 slots for the VESA-75 congura-

tion are located at the top. Partially thread two screws into the top 2 holes in the back of the

monitor. The monitor can then be hung up on the VESA Head through the two slots at the

top. Insert 2 more screws through the VESA-100 mounting holes at the bottom and tighten

all screws.

4. When removing the Monitor, the monitor arm and the monitor should be placed at the

highest position (Figure 2). Remove the 2 bottom screws from the VESA plate, loosen the

top 2 screws, and lift the monitor off the VESA plate.

Hex key (1/8”, 3/16”, M3, M4) - 1

Philips screw driver #2

Socket wrench (12mm, 1/2”) - 1

Adjustable wrench

**

** Not provided by Amico

*WARNING: Never attempt to mount or remove the arm from the rail when a monitor is installed.

*WARNING: Support AHM arm until the set screws are tightened, AHM arm can slide down when

set screws are not tightened.

*WARNING: Ensure that the AHM is in the highest vertical position and locked before mounting

or removing devices from the FIT Station.

NOTE:4 x M4 screws are provided for mounting the monitor to the VESA Head, dierent screws may

be needed if the provided screws are not the right size, standos may be needed depending on the

hole pattern on the monitor.

1

4

6

5

7

3

9

10

11

8

2

Front of the VESA 75/100

M4 mounting

hole for VESA-75

M4 mounting

hole for VESA-100

VRS

Mounting on a VRS/Ohmeda Rail

Angle the AHM from the left of the channel and guide the

adapters into the groove of the channel. Tighten screw with a

3/16’’ HEX key when V-adapter is at the desired height. When

tightened, the screw will protrude from the other side. Fasten the

nut to the screw to secure the V-adapter. If the nut cannot be in-

stalled, the adapter is not properly engaged. Check that all nuts

and screws are tightened to ensure the V-Adapter is locked.

Mounting on a Headwall

Pop out the cover from the Mounting Adapter Channel

to access the screws. Remove the 2 screws and lock

washers to free bottom Mounting Adapter. Install it into

the bottom rail by angling the upper lip into the inside

lip of the ARS, pull the lever back against the Mounting

Adapter and push the adapter into the rail. Once secure,

release the lever.

Install the remaining Mounting Adapter into the top ARS

the same way as step 1, ensuring the 2 holes on the bot-

tom Mounting Adapter can be seen through the Mounting

Adapter Channel. Secure the Channel to the bottom

Mounting Adapter using the screws and lock washers you

removed in step 1.

Mounting

Adapter Channel

ARS Adapter

installed

ARS

Rail

Quick Setup

Falcon IT (FIT)

Installation and Adjustment Instructions

Amico Accessories | www.amico.com

85 Fulton Way, Richmond Hill

Ontario, L4B 2N4, Canada

Toll Free Tel: 1.877.264.2697 l Tel: 905.763.7778

Fax: 905.763.8587

A. Rotation (AHM Side to Side)

C. FIT Post Cable Management

B. Head Tilt and Rotation

D. Height Locking Lever Adjustments

Insert Height Locking Lever

E. Counter Balance F. Cable Management

Rotate Mid Point

Rotate End Point

To adjust arm height, always be sure to loosen the height locking lever rst.

Loosening or tightening this bolt will

adjust the resistance of the arm. When properly counterbalanced, arm should

remain in neutral position when unlocked.

Counter Balance Bolt (1/2”)

Opening to the cover

Height Locking Lever

Cable Guide

Bottom of the

AHM Arm

Cable Cover

Cable Guide

Counter Balance Bolt (1/2”)

Height Locking Lever:

Rotate Counter-Clockwise

to Release

Rotate Clockwise to Lock

To rotate at rst arm To rotate at second arm

* If applicable

Cable Guide

Bottom Side of the AHM Arm

Grooves

Insert cables into cable guide, then squeeze cable guide and press onto the bottom of the AHM.

Bottom Side of Cable Cover

keyboard base

Screws for

adjusting tension

of BOTH keyboard

tray and swivel

block

Screws for

adjusting tension

of swivel block

only

Large screw

± 15°

± 360°

Small screws

1. The monitor can swivel 360° (clockwise & counterclockwise/left & right) and also can tilt

up & down by +/- 15°.

ADJUSTING TILT TENSION: Tighten or loosen the large screw on the mounting bracket and

then tighten or loosen the two smaller screws to ne tune the tension (Figure 1).

ADJUSTING SWIVEL TENSION: Slightly(one-turn) loosen/tighten the bolt at the base of

the keyboard tray, to adjust the rotational tension of both the monitor and the keyboard tray,

slightly loosen/tighten the 3 Philips head screws at the base of the keyboard tray. (Figure 2)

1. There are 2 FIT cable guide-channels in the

Swivel post, which is covered by the Swivel

Post Cable Cover.

2. Pop out the Swivel Post Cable Cover, take

your power cable for your All-in-one and place

the cable gently into the guide-channels to-

wards your AHM(Figure 1, 2). Take your cables

from the keyboard tray and place the cables

into the guide-channels toward your All-in-one.

Figure 1

Figure 1 Figure 2 Figure 3

Figure 2

*WARNING: After monitor is installed, tighten large and small tilt adjustment screws to tightest

position possible with the weight of the monitor attached. Alternate between tightening large

screw and small screw until appropriate tension is reached.

*WARNING: Be sure to support the monitor if adjusting the tilt angle with monitor mounted.

*WARNING: Do not bunch cables together on one cable guide-channel. Use separate channel for each cable

Bolt at extension arm

AHM extension arm

Extension Arm rotated

Bolt at

adapter

To rotate AHM:

Second Arm rotated

Cable guide

channel Cable laid Swivel Post

Cable Cover

Other manuals for Falcon IT

2

This manual suits for next models

1

Other Amico Rack & Stand manuals

Amico

Amico SSM Arm Guide

Amico

Amico Gooseneck User manual

Amico

Amico HMA-VESA-SPK-PLT Technical specifications

Amico

Amico BARCDHLD2-LCD Guide

Amico

Amico RS-42-PKS Series Original operating instructions

Amico

Amico ARS User manual

Amico

Amico BARCHLD2 Product manual

Amico

Amico VRS User manual

Amico

Amico Falcon IT User manual

Amico

Amico AHM Service manual