10 N5X Construction guide

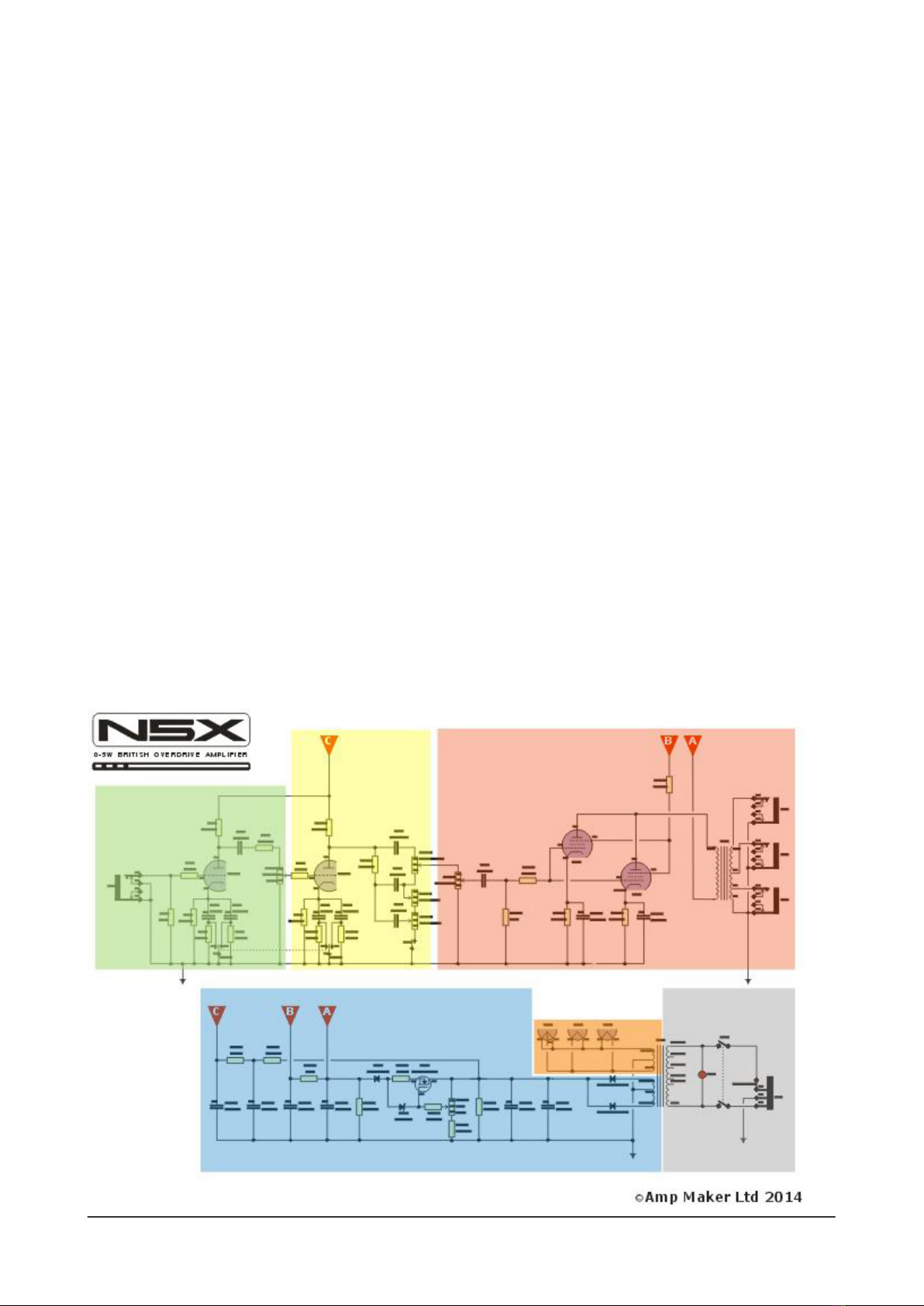

Along the top, there's your guitar signal path from left to right:

* green box = guitar input, rst amplication stage and Gain control

* yellow box = second amplication stage and TMB tone controls

* red box = Master volume and power stage

Along the bottom, there's the power supply, with the mains entering at bottom right:

* grey box = mains-side circuit

* orange box = heater supply for the valves

* blue box = power supply with VCB

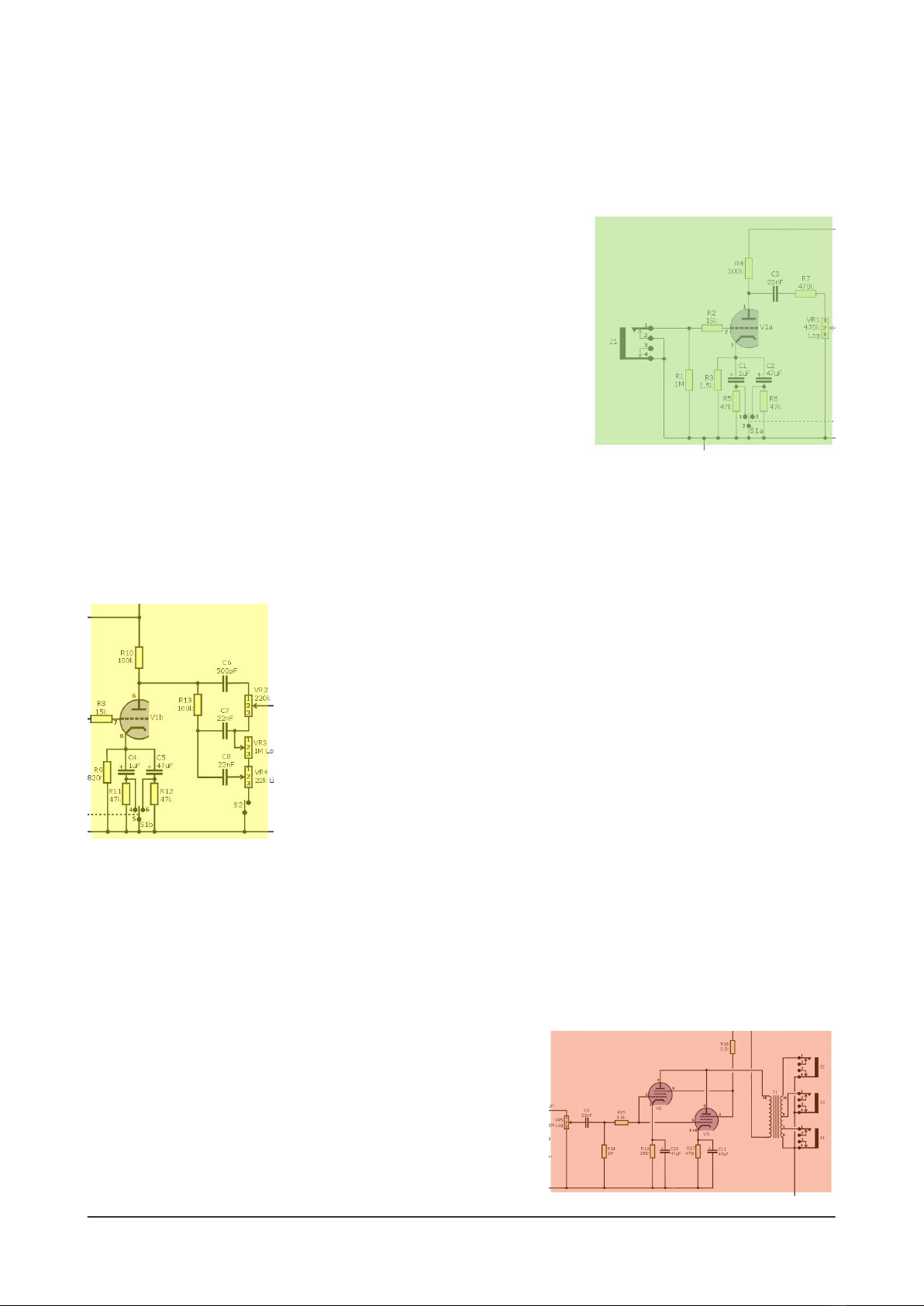

First amplication stage

The guitar input socket is shown at the top left, and it feeds into the

light green shaded section. This is the rst stage of the amplier and

it uses one half of the ECC83 preamp valve (V1a) to amplify the low-

level guitar signal.

The resistors and capacitors around V1a set the way that it works

- how much current ows at idle and what EQ is applied to the signal passed along to the next stage.

There's also one half of the Boost switch (S1a) here - it controls which is any capacitors are used to add

an extra boost to part of the guitar signal.

The nal part of this section of the circuit includes the Gain pot, which controls how much of this

boosted signal is fed into the second stage.

Second amplication stage

The guitar signal - still fairly clean so far - is fed into the second part of the

amp (shaded in light yellow in the block diagram). This uses the other half of

the ECC83 preamp valve, V1b. Many of the components are similar to the rst

stage, and there's the other half of the Boost switch, here, too. If the Gain

control is set high, the incoming signal will overdrive this second amplication

stage to create some preamp distortion.

The output of this stage then runs through a network of resistors,

capacitors and pots that allow you to control the treble, middle and bass

frequencies of the signal that will be passed along to the power valve. This is a

'lossy' tone stack, meaning that in order to adjust the TMB frequencies, it must throw away part of the

amplied signal. With the Bypass switch (S2) enabled, however, you can choose to have the full output

of this stage passed along to the power valve.

Power stage

The reddish shaded section shows the power stage, which includes the Master volume control, the

power valve and the output transformer. The Master volume is the simplest part - a pot that lets you dial

in how much signal the power valve receives. Low settings for

cleaner tones, and at higher settings you can overdrive this

valve to get maximum distortion.

The N5X includes a 'noval' socket for EL84 valves (like the

SE-5a), but also has an octal power valve socket, V3. So you can

plug in a 6V6/6L6/EL34/etc instead of the EL84. These bigger

valves have dierent overdrive characteristics and tones, and