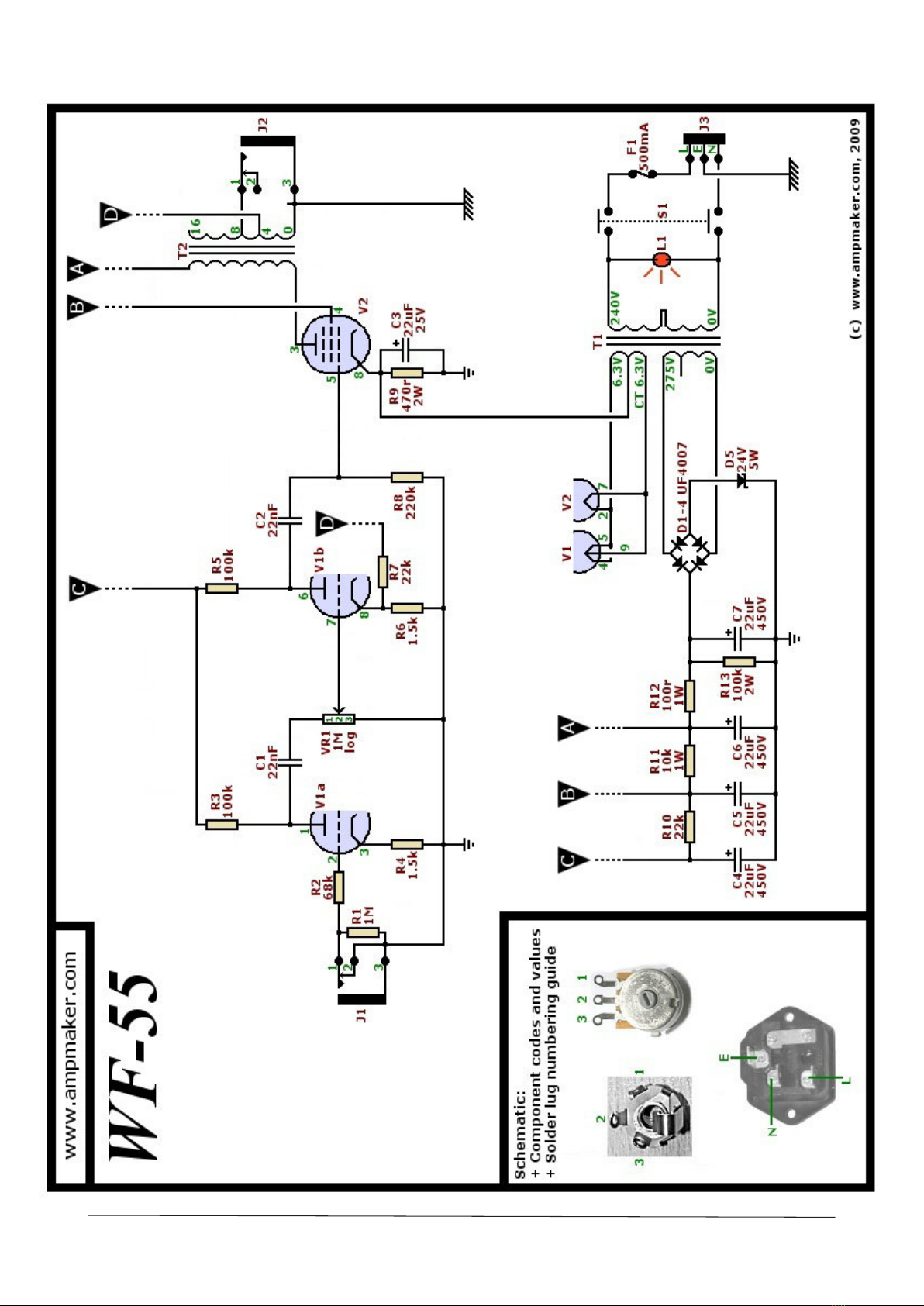

6 WF-55 Construction guide

Schematic

All components are numbered on the

schematic (R1, C3, D4, etc), so that you

can relate this schematic to the Kit

contents listing (earlier) and the turret

board layout (later).

It's the specic values in the circuit

that combine to make the amplier

work and sound the way that it does.

For example, capacitor C1 does two

jobs. The rst is to block the high DC

voltage (supplied to the rst stage of

the preamp via resistor R3 and R10)

from feeding into the input of the

second amplication stage; any value

of capacitor would work for this task.

The second job that the capacitor does

is to control the amount of lower

frequencies in the amplied guitar

signal that are passed from the rst

amplication stage to the second -

higher values allow more bass through,

lower values allow less.

Build now, tweak later

It's the ease with which you can alter

individual components in an amp

circuit that makes hand-wired amps so

appealing. For example, you can swap

in components with the same ratings

but dierent values to change the

response of part of the circuit. This is

the real beauty of building your own

amp - you can ne-tune it to the tone

you like.

It's best to get your amp up and

running rst, by sticking to the

components specied on the

schematic and supplied with your kit.

There are many ways to tweak the

vintage 5F1 Champ circuit, and you can

decide if you want to try that when the

amplier is working properly as

standard. While it may be tempting to

leap ahead and increase the bass

frequencies by using other capacitor

values, for example, doing this in the

wrong part of amp circuit may

inadvertently cause your amp's

distortion tone to become 'muddy'.

Solder lug numbering

Look closely at the schematic and you'll see numbering for

the solder lugs of certain components. For example, the jack

sockets, pot and mains input socket each have 3 solder lugs.

To help avoid confusion, your schematic

includes numbers next to each

connection for these components, and

at the bottom left of the schematic

there's also an annotated photo

reference for each.

Valve sockets have even more

solder lugs. There are nine solder lugs for

the preamp valve, numbered clockwise,

starting at the gap (below). The second

and larger valve socket is an 8-pin type

(for the 6V6 power valve). It has a small

keying 'notch' in the central round hole -

which you can just see here at the 3-

o'clock position. The pin numbers (1 to 8)

are moulded in the underside next to

each solder lug, working clockwise

from this keying notch. However,

they're almost impossible to see in

anything other than the brightest

light, so I've added annotations here

for reference.

The picture opposite shows the WF-55's full schematic - the same

circuit as the block diagram and with all component values added

and with numbered lugs for all o-board components.