4

CHARGING MODES CLASSIFICATION

RATED CURRENT AND VOLTAGE FOR DIFFERENT CHARGING MODES

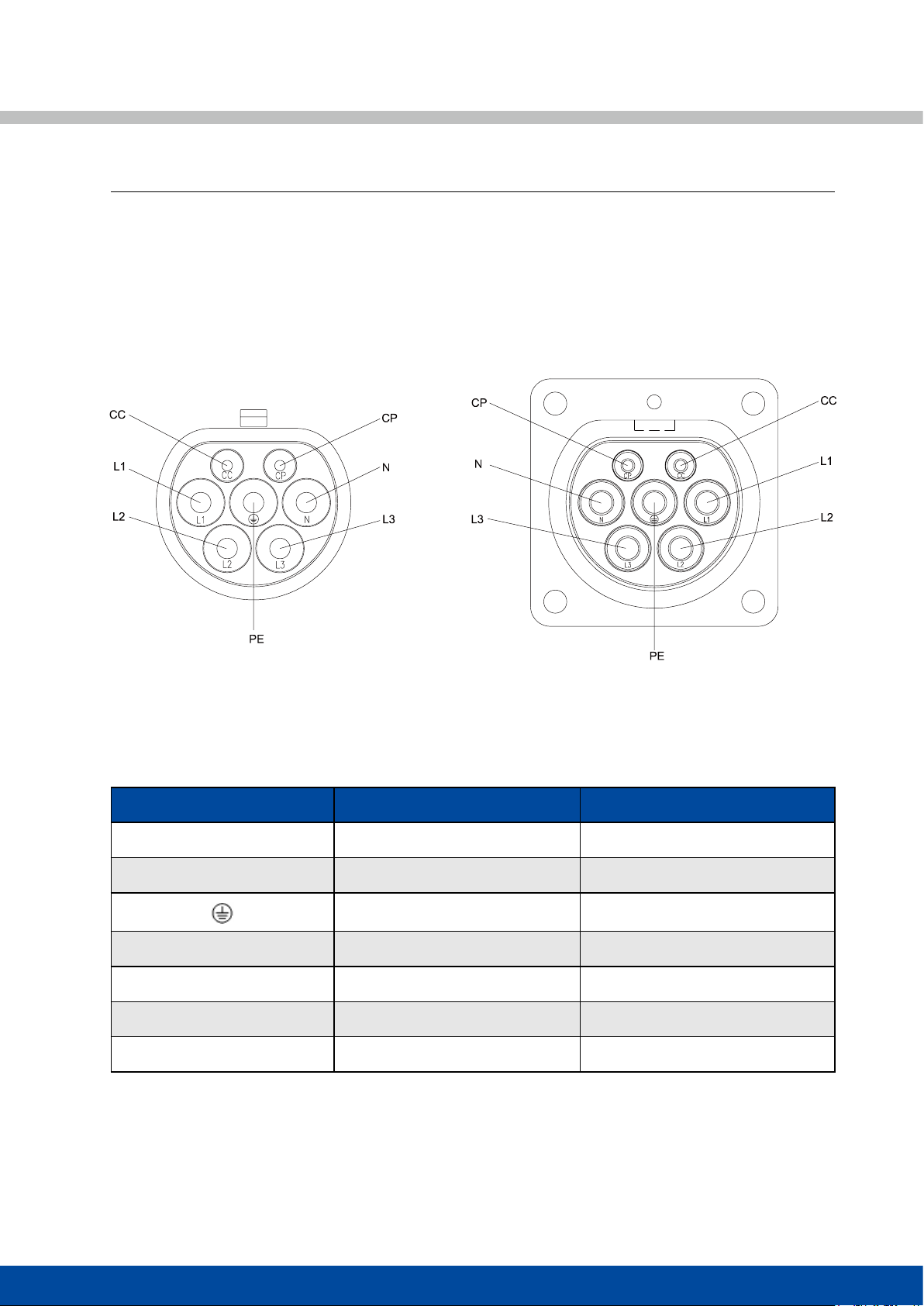

Charging Mode Couple Type Rated Voltage Rated Current

2AC coupler 250V AC 16A

3AC coupler 250V/440V AC 32A

4

DC coupler 750V/1000V DC 80A

DC coupler 750V/1000V DC 125A

DC coupler 750V/1000V DC 250A

Remarks:

All types of charging modes should be connected with residual current operated circuit-breakers and overflow

protective device. Residual current operated circuit-breakers should be compliant with GB/T 16916.1 or GB/T 16917.1

requirements.

CHARGING MODE 2:

When connecting electric vehicle to AC network, the plug and socket-outlet at power supply side shall comply with

requirements of GB 2099.1. Phase line, neutral line and protective earth conductor shall be used at power supply side

and the residual current operated circuit breaker shall be used at power supply side.

CHARGING MODE 3:

When connecting electric vehicle to AC network, the plug and socket-outlet at power supply side shall comply with

requirements of GB 2099.1. Phase line, neutral line and protective earth conductor shall be used at power supply side

and in-cable control box is installed in the charging connection cable.

CHARGING MODE 4:

When connecting electric vehicle to AC network, use special power supply equipment. Directly connect the electric

vehicle with AC network and install control guide device on the special power supply equipment.