THANK YOU FOR CHOOSING TO EQUIP YOUR VEHICLE WITH

OUR PRODUCT

Our premium products will enhance your 4x4 and provide you with the

following great features:

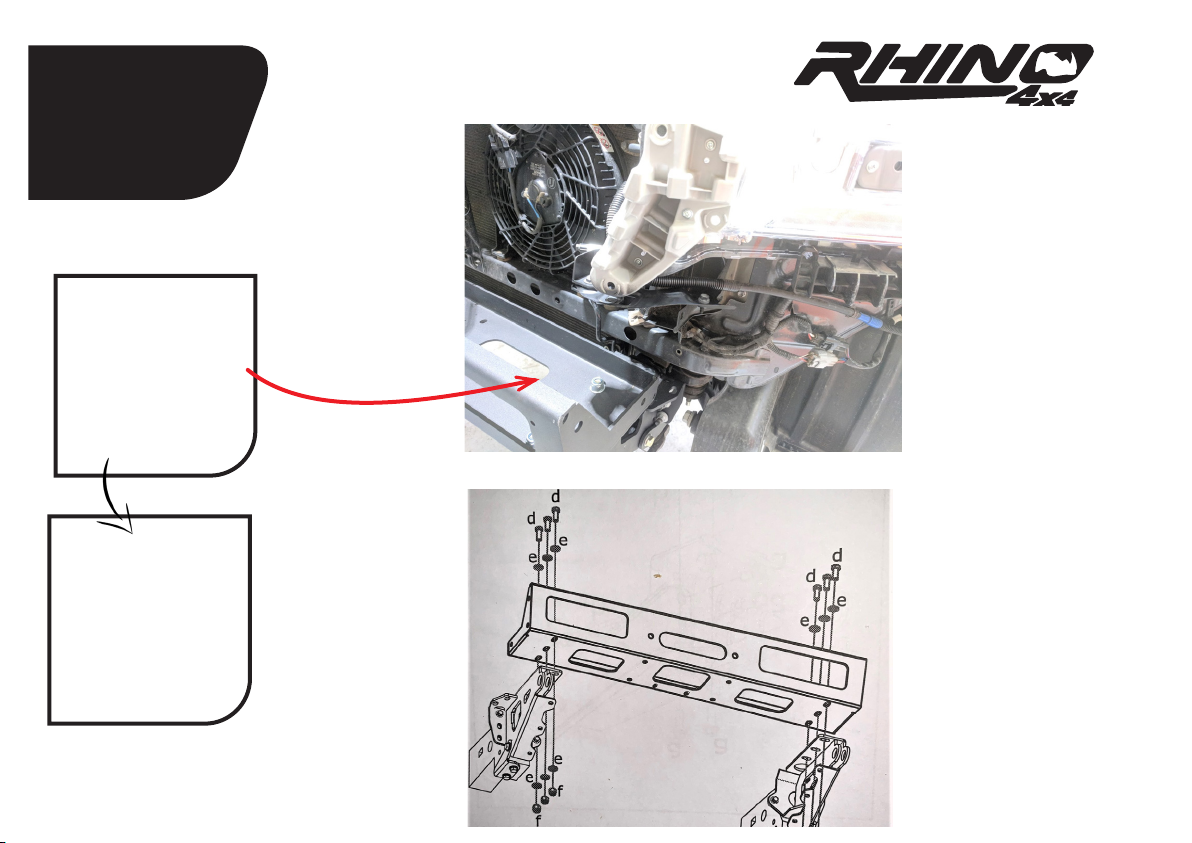

• Our bumper is designed to follow the original lines and aesthetics of

your vehicle.

• Your vehicles approach angle will be greatly improved and also provide

you with recovery points and increased vehicle protection.

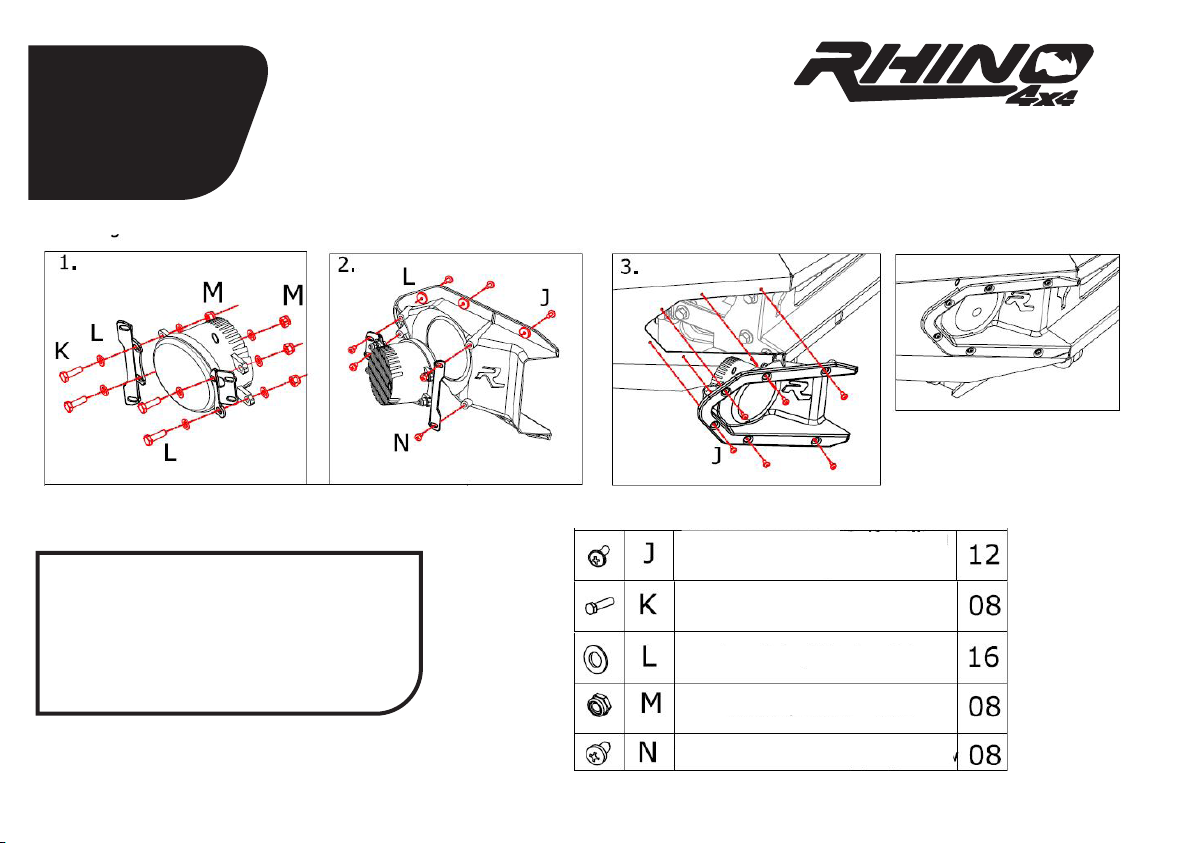

• Our modular system allows you to replace

parts individually.

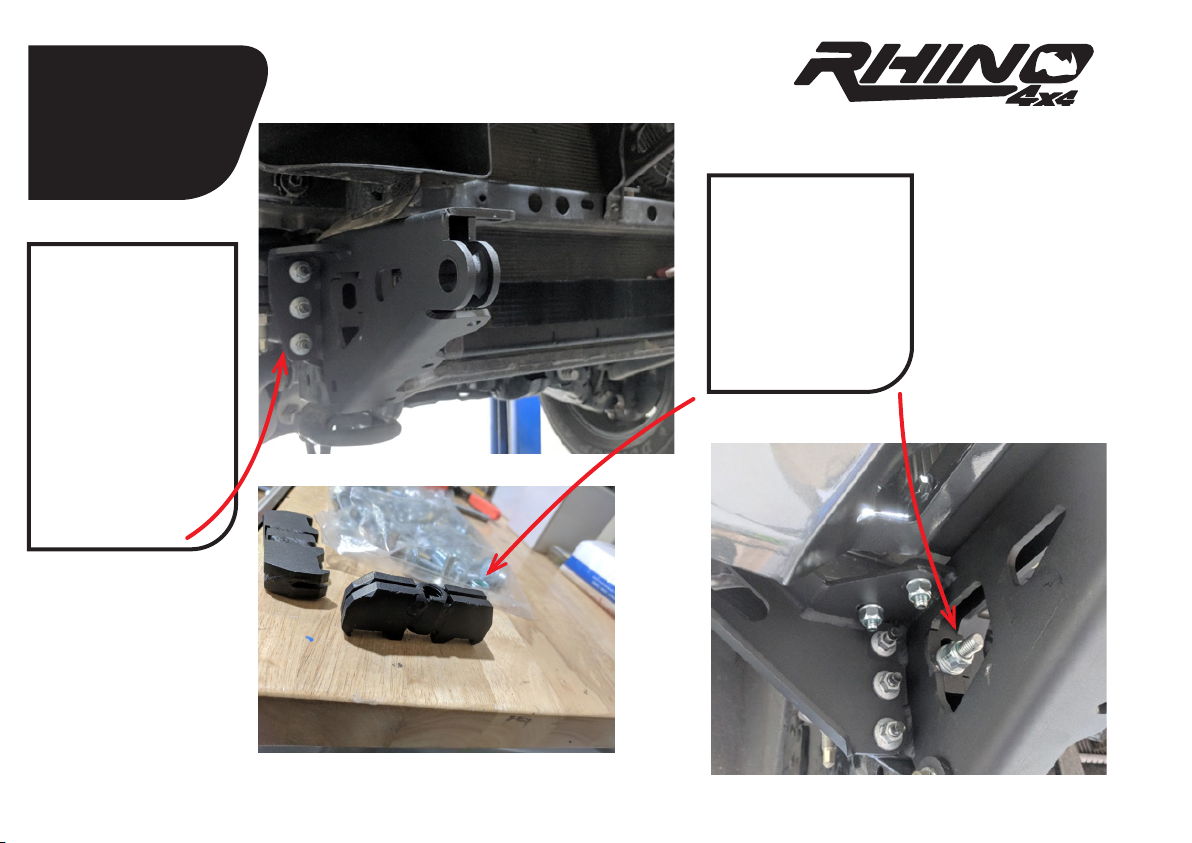

• We do not cut the original plastic bumper, this can be stored and

reinstalled at any time.

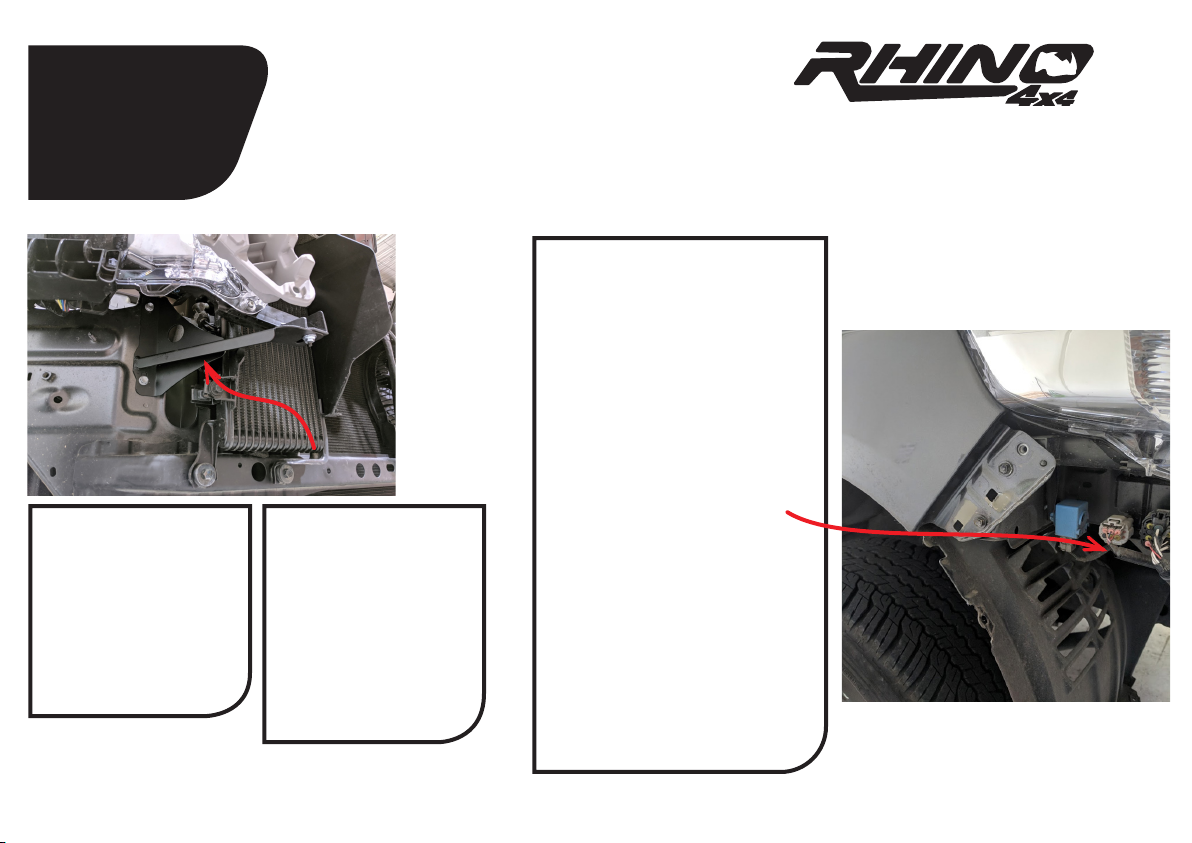

Before commencing with the installation it is important that you read

and understand these installation instructions. If you need any technical

adviceplease contact you closest Rhino 4x4 dealer

or contact us via www.rhino4x4.com.au/contacts

If the customer or nominated agent chooses to self-install, or have the

product(s) installed including any modification at a non-accredited

Rhino4x4 Re-Seller/Workshop, Rhino4x4 is not responsible or liable for any

loss suered, including indirect or consequential damages caused to the

vehicle during and arising from or in relation to such installation

ATTENTION

DO NOT attach VFPS to the

vehicle using any fixing points

not intended for this purpose.

DO NOT use this product

on any other vehicle make

or model, other than those

specified.

DO NOT remove the warning

labels or Rhino 4x4 logo from

the VFPS.

DO NOT modify the VFPS in

any way.