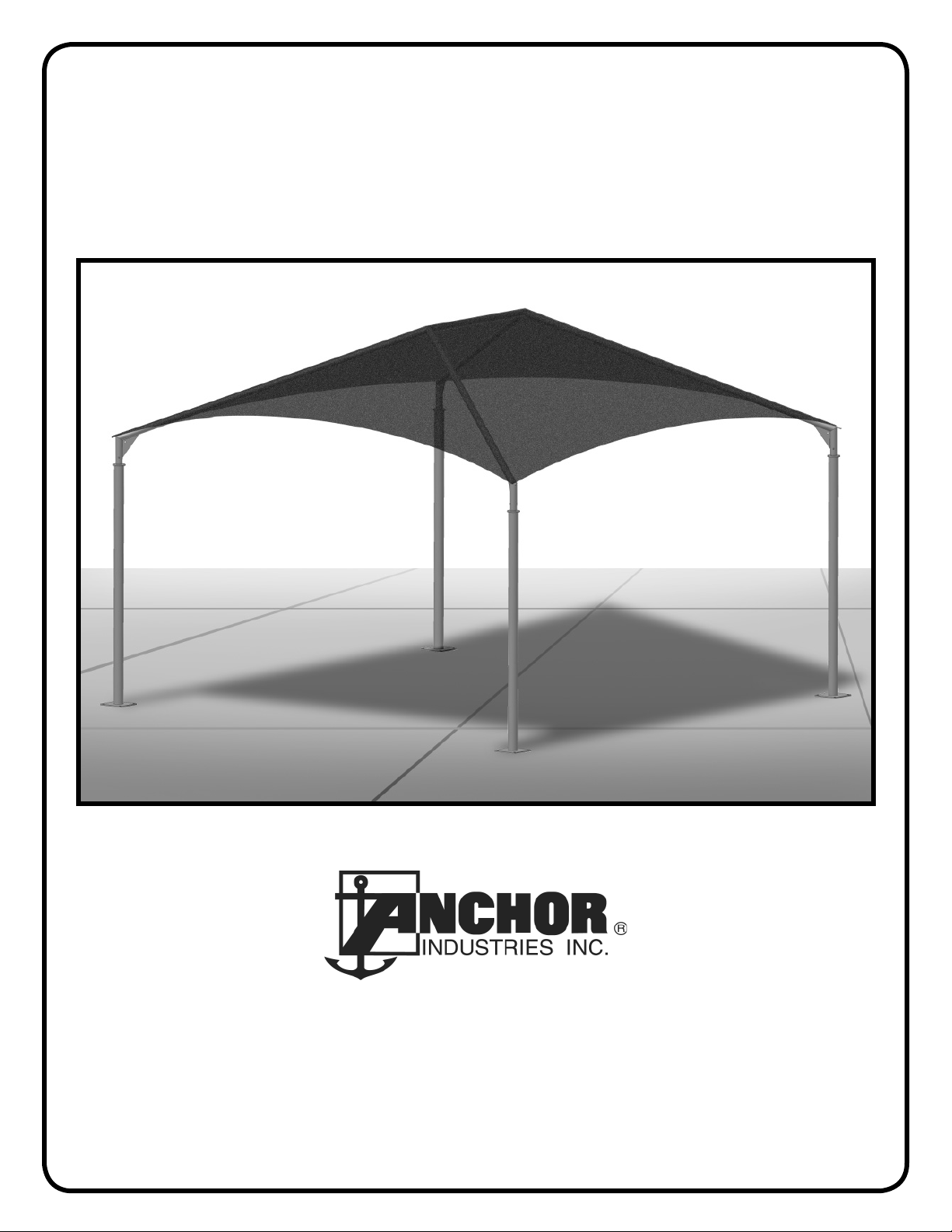

Anchor Perfectshade User manual

Assembly Instructions

PS 1014

PRODUCTION FACILITIES:

EVANSVILLE, IN

PHONE: 800-322-8368

or 812-867-2421

FAX: 812-867-4636

EMAIL: [email protected]

www.anchorinc.com

SALES OFFICES:

7701 HIGHWAY 41 N

EVANSVILLE, IN 47725 USA

EC 4829

Perfectshade®

Warning: The Perfect Shade Structure is intended for concrete Install only. Installer is solely re-

sponsible for evaluating the quality of the concrete and its suitability for this structure.

Concrete installation surface must be level.

Manpower Required:

Three experienced installers should be able to assemble any size frame with fabric in two hours.

Caution:

Please read through this assembly manual completely before beginning your installation. Be sure the proper

equipment and safety precautions are in place. We hope that you enjoy the design features of the Perfect Shade

Structure.

1. Be aware to avoid contact of frame sections with any overhead power lines near the site.

2. Consult the local utility company prior to installation in order to avoid all underground power lines and gas

lines or other utility easements.

3. Keep site clear of debris to avoid tripping, especially while carrying frame parts or bundle of fabric.

4. When moving frame sections by hand, use proper lifting techniques to protect the back, and avoid pinching

fingers while making hardware connections.

5. Do not drag bundle of fabric on concrete, asphalt, or ground as this can cause damage to the fabric from abra-

sion through the bag.

6. The installation method described here requires coordination of tasks between workers. A safe installation is

dependent on that coordination. Work cooperatively as a team.

7. This tent is manufactured for use as a temporary sun shade structure. Evacuation is recommended if threaten-

ing or windy weather occurs.

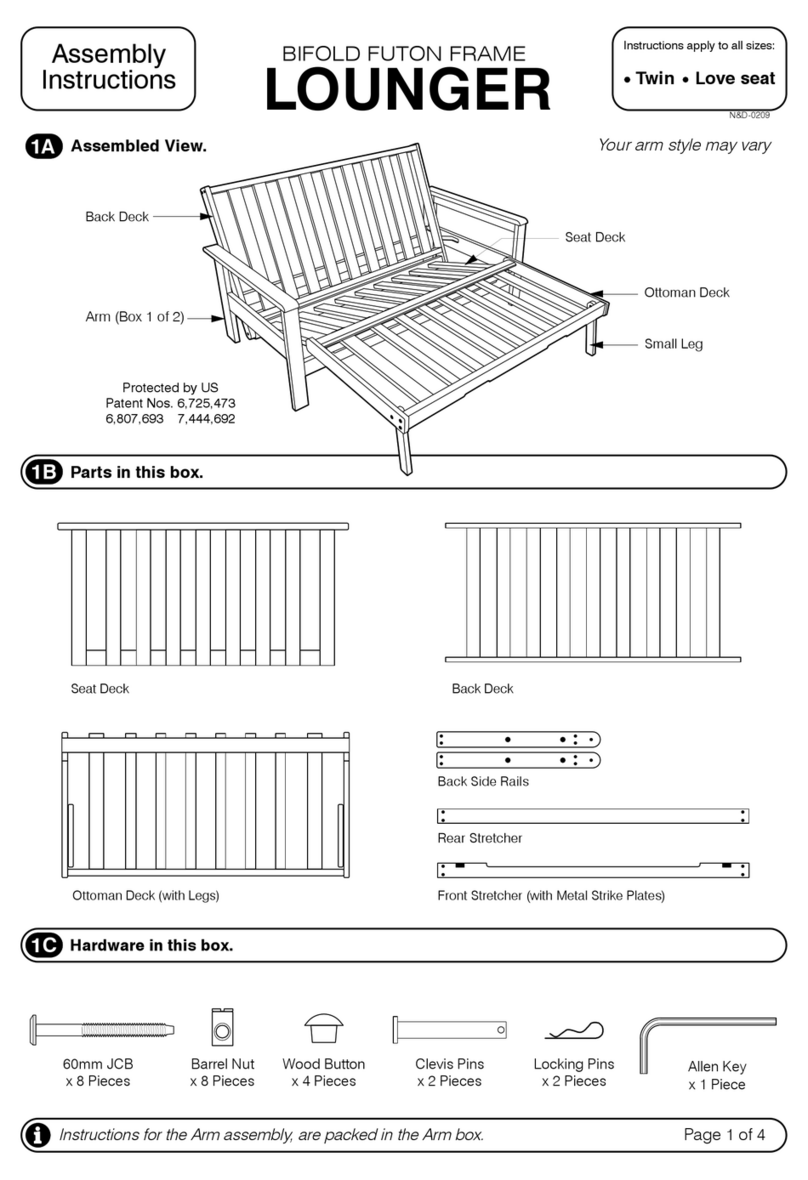

Parts List

Part Name Qty. for (1)

Frame

Upright with Base Plate 4

Hip Weldment 4

Peak Weldment 2

Ridge Tube 1

Hex Head Cap Screw 1/2 x 3 1/4” 4

1/2” Nylock Nut 4

Fabric top in bag with wire rope & clamps 1

Installation Kit (purchased separately) 1

Hip Weldment

Ridge Tube

Fabric top Bag

with wire rope & clamps

attached to top.

Upright with

Baseplate

Peak Weldment

1/2” Nylock

Nut

1/2” Hex

Head Cap

Screw

Installation Kit

Come-a-long (2)

Pull Rope (2)

Eyebolt (2) Neoprene

Washer (4)

Wing nut

(2)

(4) Wire Rope

Clamps

(spares)

2

Step 1:

Choice of 1/2” diameter anchoring devices are at the discretion of the customer and not supplied by Anchor Indus-

tries.

Place anchoring devices as shown on the plan view below. (4) anchoring devices per base plate.

Note: For Your Convenience, (1) Template is supplied at the center of this manual.

Base Plate Layout

Base Plate

(Typ. 4)

Base Plate

(4) 3/4” dia. holes for

anchoring devices.*

Dimensions are to center

points of base plates un-

less noted otherwise.

*NOTE: The installer is

solely responsible for

determining the proper

anchoring device.

DIMENSION CHART

FOR BASE PLATE LAYOUT

Size A B C D E

10’ x 10’ 9’- 10” 9’-10” 10’-8 1/2” 10’-8 1/2” 13’-10 7/8”

10’ x 15’ 14’- 10” 9’-10” 15’-8 1/2” 10’-8 1/2” 17 -9 9/16”

10’ x 20’ 19’- 10” 9’-10” 20’-8 1/2” 10’-8 1/2” 22’-1 5/8”

15’ x 15’ 14’- 10” 14’-10” 15’-8 1/2” 15’-8 1/2” 20’-11 3/4”

20’ x 20’ 19’- 10” 19’-10” 20’-8 1/2” 20’-8 1/2” 28’-0 9/16”

20’ x 30’ 29’- 10” 19’-10” 30’-8 1/2” 20’-8 1/2” 35’-9 7/8”

“C” Ref. dimension

“A”

“E” Diagonal

“D” Ref. dimension

“B”

Corner AA

Corner BB Corner DD

Corner CC

Ridge

Frame shown in

dashed lines

Caution: Concrete installation

surface must be level.

3

Step 2

Layout frame members as shown above in their approximate final placement. (See base plate layout in Step 1)

Step 3

Stand one of the uprights over the installed anchors at Corner AA. (See Figure 2)

Warning: Examine the orientation of the upright so that when hip is attached it will be pointed toward the ridge. (See

Figure 3)

Step 4

Fasten the base plate to the anchors and tighten to snug. (See Figure 4)

Figure 4

Remove template

before base plate

installation.

Corner BB

1st Base Plate

Template

Corner AA

2nd Base Plate

Template taped to

concrete surface.

Ridge

Figure 2

Corner CC

Base Plate

Template Corner DD

Base Plate

Template

Upright

Slide hip down

over upright align-

ing holes.

Figure 3

Note that hole thru

top of upright is

perpendicular to

hip and aligns with

hole in hip.

Upright

Hip

Peak Weldments

Note the orientation of the corners to the ridge. Base plates

MUST be laid out in this order. -- AA, BB, CC and then DD.

Hip

Note: All uprights are iden-

tical, but proper orientation is

critical as noted in Step 3.

4

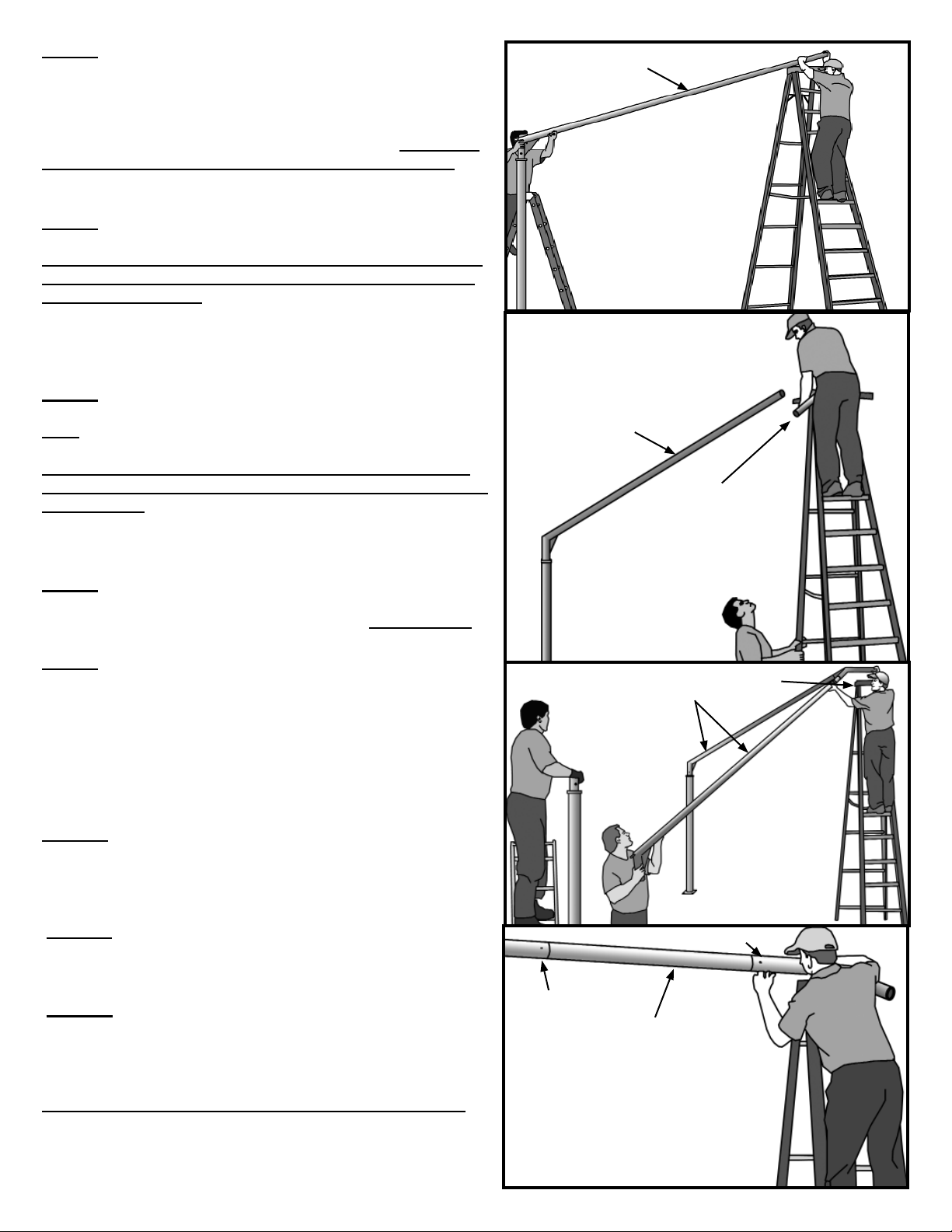

Step 5

Attach the first hip. Lift the Peak end of the hip up by climb-

ing a ladder (ladder placed at the approximate position of

the peak) (See Figure 5). Another person at the upright on a

ladder must direct the person at the peak end of the hip so

that it may be slipped into place on the upright. Make sure

the holes in the upright are aligned with those in the hip.

(See Figure 3) Loosely install bolt at hip to upright.

Step 6

Attach the Peak weldment to the hip. (Figure 6)

Warning: Examine the orientation of the peak weldment so

that the angles of the hips and ridge look to be pointing in

the proper directions.

Do not insert the bolt until later. For safety reasons, have

the person at the peak stay at that position until all hips are

installed.

Step 7

Erect the second upright at Corner BB. The second upright

must be oriented as shown in Base Plate Layout and Figure

2.

Warning: Again examine the orientation of the upright so

that when hip is attached it will be pointed toward the ridge.

(See Figure 3)

Fasten the base plate to the anchors but with only a loose fit

at this time for aid in installation.

Step 8

Lift the peak end of the second hip up and place on the peak

weldment. Do not insert the bolt until later. (See Figure 7)

Step 9

It may be necessary to lean or tip the upright to align it so

that the hip can be slipped over the top of the upright. Once

the hip is on the upright, check to be sure that the holes in

the hip line up with the holes in the upright. If they do not

align, your upright may be turned incorrectly.

Loosely install bolt at hip to upright.

Tighten the base plate anchors to snug.

Step 10

Bolt the ridge tube to the peak weldment. Bolt the other

peak weldment to the other end of the ridge tube. (See

Figure 8)

Step 11

Erect the third and fourth uprights (corners CC and DD).

Follow the instructions from Step 7 thru Step 9.

Step 12

Insert bolts for peak weldment into remaining hips. Tighten

all base plate bolts and tighten the bolts and nuts from the

hips to the uprights at this time.

The Frame portion of the Perfect Shade is complete.

Figure 8

Ridge

Figure 5

Peak

Figure 6

Figure 7 Peak

Hips

Hip

Hip

Peak

Peak

Note: 12’ ladder used

at peak for 20’ frame.

Shorter ladder may

be used on smaller

frames

5

Other Anchor Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual