— 5 —

Important Safety Information

WARNINGS

• Donotstoreorusegasoline,liquidpropanecylinderor

other ammable vapors and liquids in the vicinity of this

or any other appliance.

• Gasleakscannotalwaysbedetectedbysmell.

• Gassuppliersrecommendthatyouuseagasdetector

approved by UL or CSA. For more information, contact

your gas supplier.

• Installationandservicemustbeperformedbyaqualied

installer, servicer or the gas supplier. Ask your dealer

to recommend a qualied technician and an authorized

repair service. Know how to shut off gas supply at

the meter and disconnect the electrical power to the

appliance at the circuit breaker or fuse box in case of an

emergency. Have the installer show you the location of

the appliance gas shut-off valve and how to shut it off

if necessary.

• Donotrepairorreplaceanypartoftheapplianceunless

specically recommended in this manual. All other

servicing should be done only by a qualied technician.

This may reduce the risk of personal injury and damage

to the appliance.

• If the information in this manual is not followed

exactly, a re or explosion may result causing

property damage, personal injury or death.

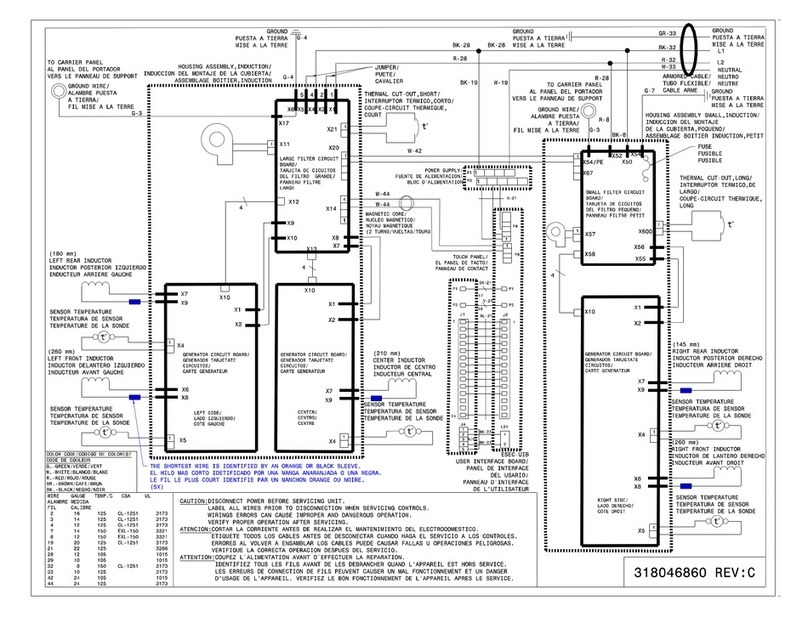

• Disconnectpowerbeforeservicing.

• Nevermodifyoraltertheconstructionoftheappliance

by removing panels, wire covers or any other part of

the product.

• Overheadrangehoods,whichoperatebyblowinga

downward air ow on to the appliance, shall not be used

in conjunction with gas appliances other than when

the hood and appliance have been designed, tested

and listed by an independent test laboratory for use in

combination with each other.

• Ifapplianceislocatednearawindow,NEVERhanglong

curtains or paper blinds on that window. They could

blow over the surface burners and ignite, causing a

re hazard.

• Ensurethattheroomiswellventilatedbykeepingtheair

intakes open and in good working order or by installing

an extractor hood with discharge pipe. If the appliance

is used intensively for a long time the effectiveness of

the ventilation will have to be increased, for example

by opening a window or increasing the power of any

electric extractor fan.

• Flammablematerialsshouldnotbestoredonthe

appliance or near surface units. This includes paper,

plastic and cloth items, such as cookbooks, plastic

ware and towels, as well as ammable liquids. Do not

store explosives, such as aerosol cans, on or near the

appliance. Flammable materials may explode and result

in re or property damage.

• Maintenance: Keep appliance area clear and free from

combustible materials, gasoline, and other ammable

vapors and liquids.

• Storage in or on the appliance: Flammable materials

should not be stored on or near surface units.

• Donotstoreitemsofinteresttochildreninthecabinets

above the appliance. Children should not be left alone

or unattended in the area where appliance is in use. Do

not allow children to climb or play around the appliance.

They should never be allowed to sit or stand on any part

of the appliance. Children climbing on the appliance to

reach items could be seriously injured.

• DONOTTOUCHTHECOOKINGSURFACE,THE

BURNERS, GRATES, OR ANY AREAS NEAR THEM.

Surface burners or appliance may be hot even though

ames are not visible. Areas near surface burners or

appliance may become hot enough to cause burns.

During and after use, do not touch, or let clothing or

other ammable materials touch these areas until they

have had sufcient time to cool. Among these areas are

the cooktop and surfaces facing the cooktop.

• Donotwearloose-ttingorhanginggarmentswhile

using the appliance. Do not let clothing or other

ammable materials contact hot surfaces.

• Smothergreasereswithapanlid,orusebakingsoda,

a dry chemical or foam-type extinguisher.

• UseanextinguisherONLYif:

- You know you have a Class A, B or C extinguisher, and

you already know how to operate it.

- The re is small and contained in the area where it

is started.

- The re department is being/has been called.

- You can ght the re with your back to an exit.

• Whenheatingfatorgrease,watchitclosely.Fator

grease may catch re if allowed to become too hot.

• Useonlydrypotholders.Moistordamppotholderson

hot surfaces may result in burns from steam. Do not

let potholders touch hot heating elements, the ame or

burners. Do not use a towel or other bulky cloth instead

of a potholder.