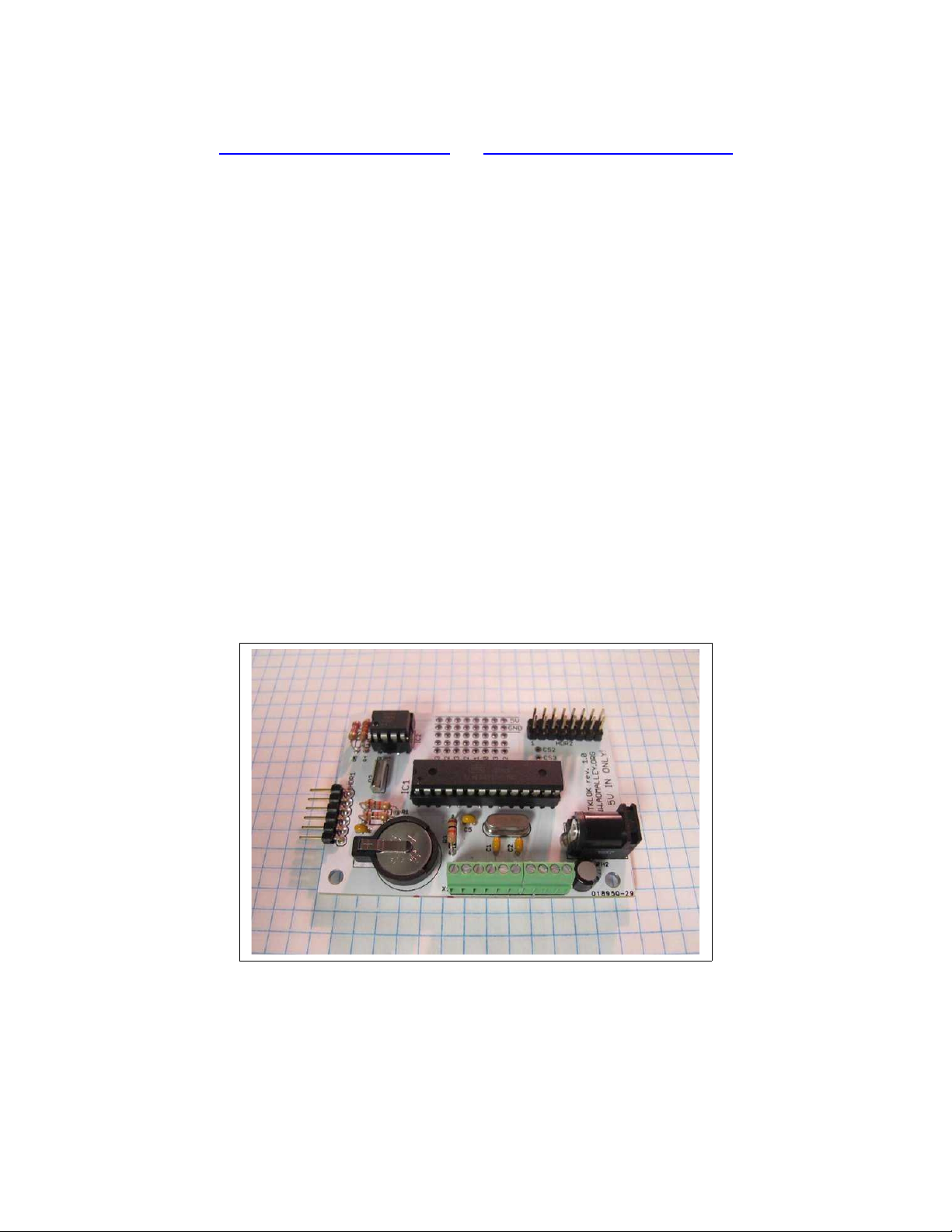

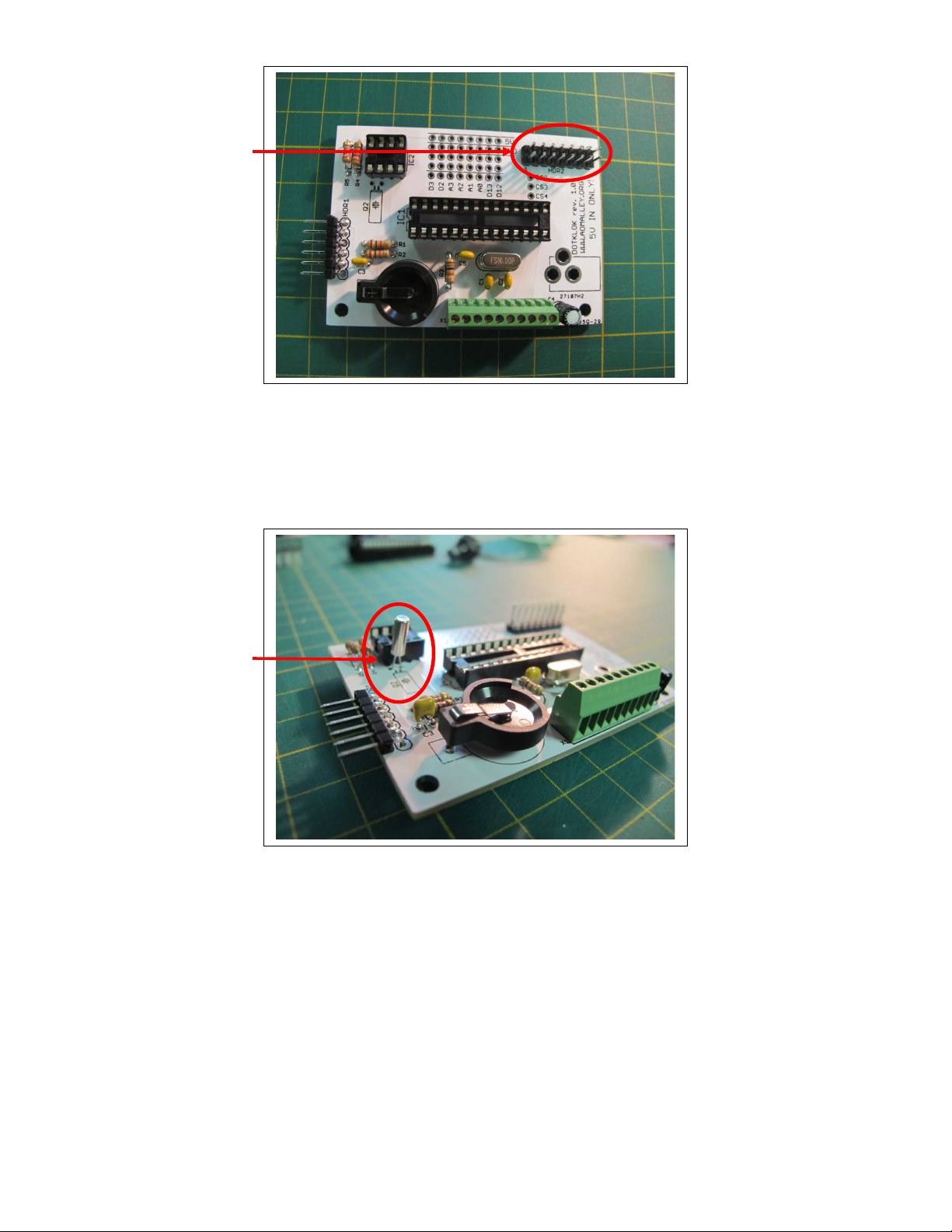

All parts sit on the top of the board and are soldered from the bottom.

Please refer to the bill of materials (BOM):

www.aomalley.org/dotklok/files/DOTKLOK_bom_illustrated.pdf

for an illustrated parts list.

Take care when unpacking the kit components, there are several small parts,

and no extras have been provided. TIP: the foam housing for the LED screen

makes for a handy parts tray while assembling DOTKLOK.

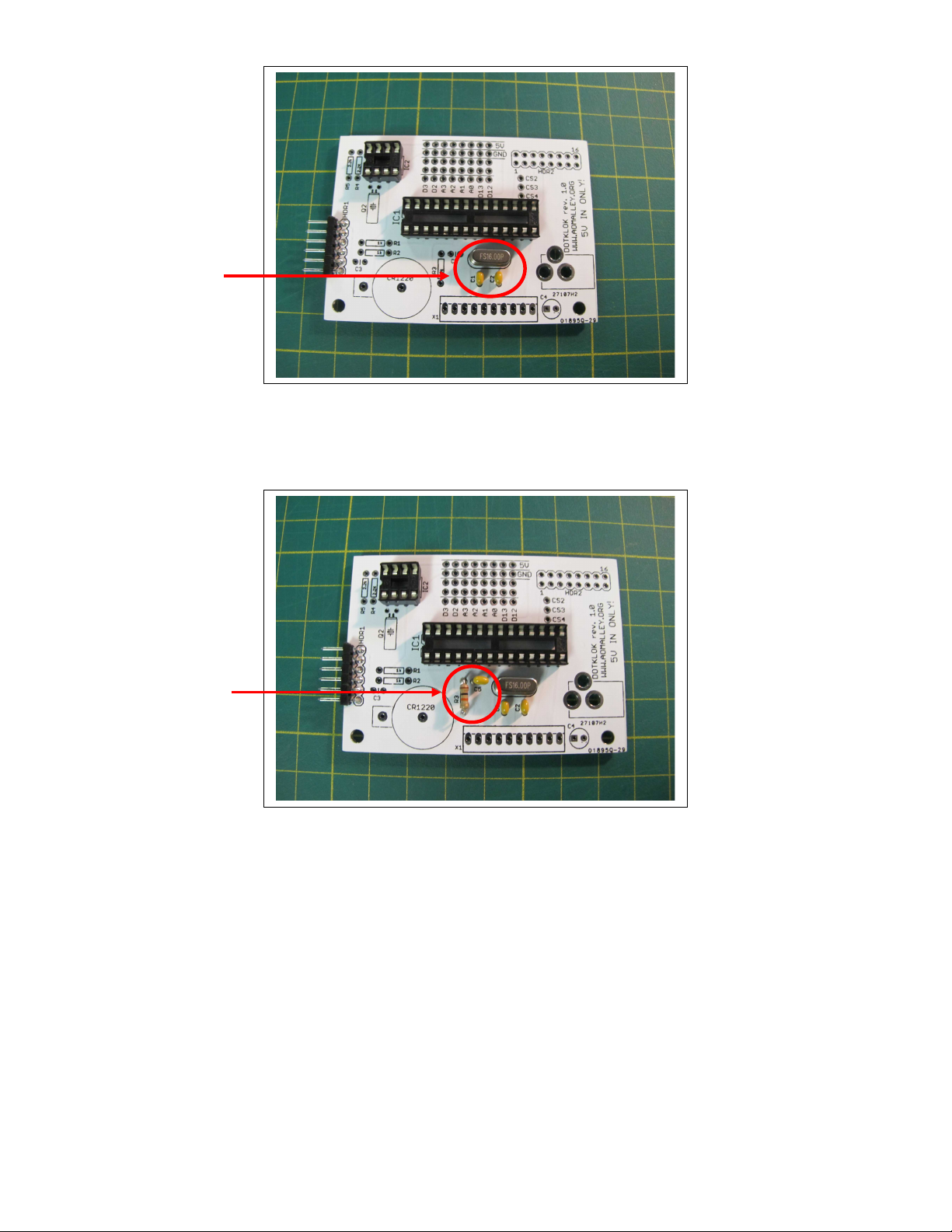

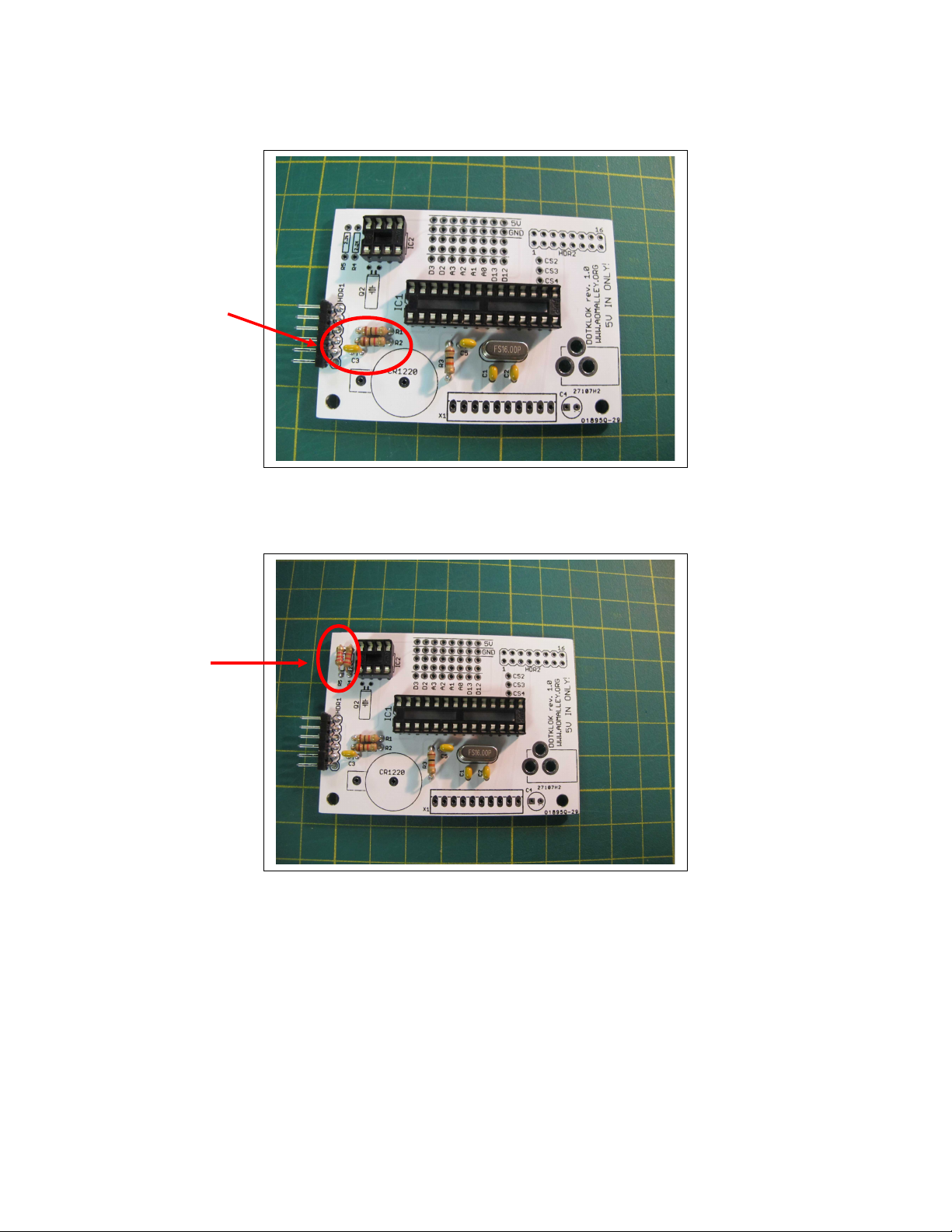

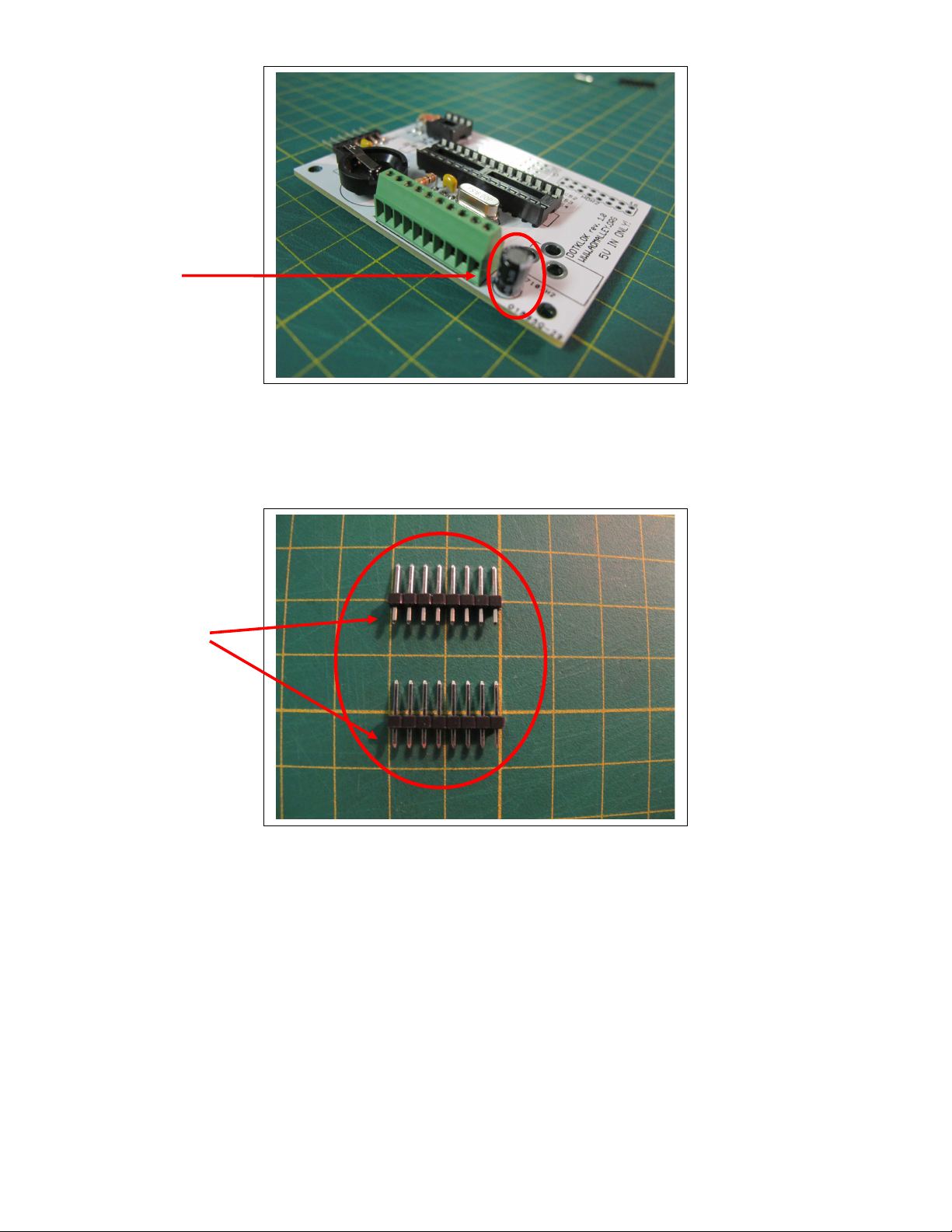

If your PCB is labeled “DOTKLOK . ” you will need to solder a wire

across the JP pads in order for the board to work with the power supply

included with your kit. Although a specific wire has not been included for

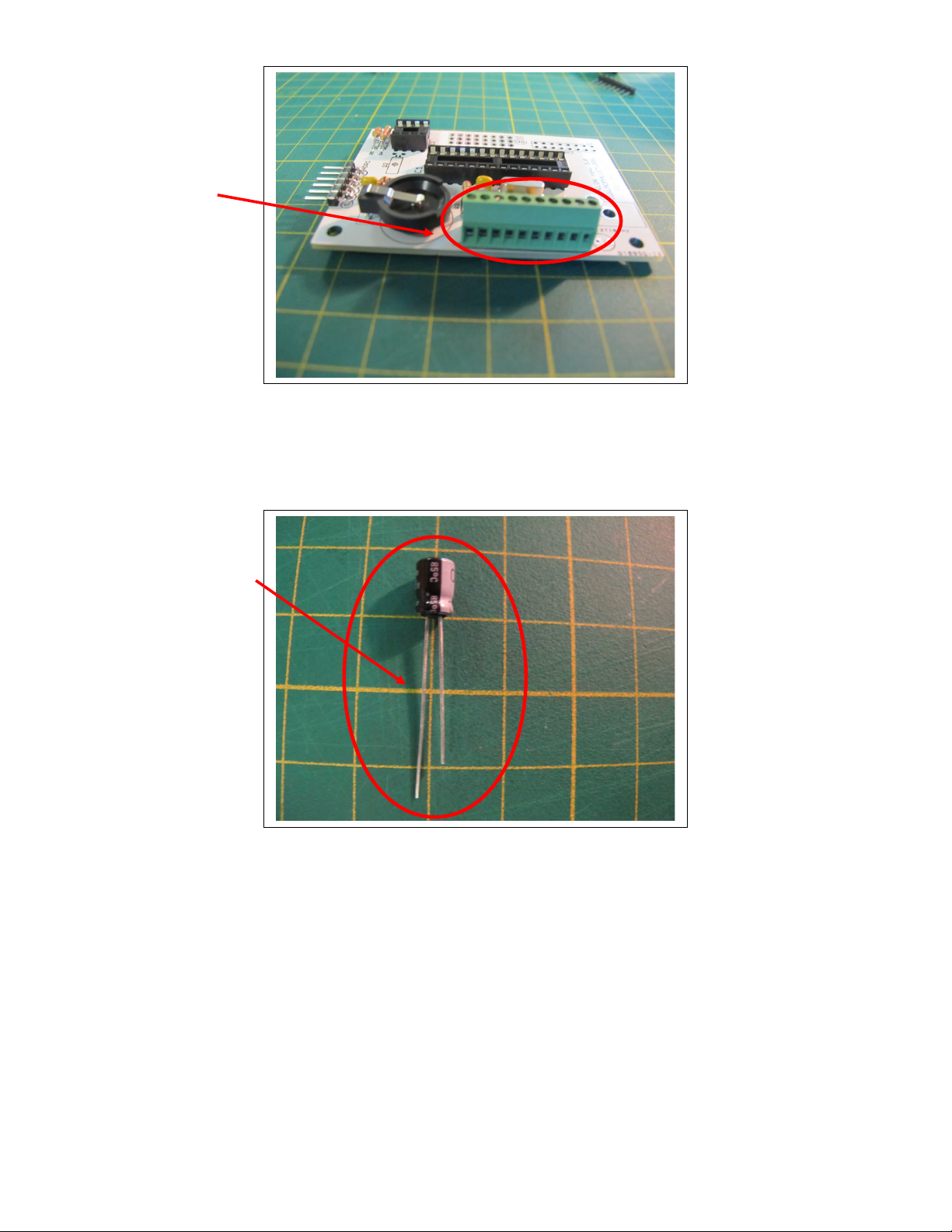

soldering this jumper, you can can use one of the cut-off leads from a

resistor or capacitor soldered in the following steps.

2

Solder a wire

across JP