10

GRILLGRILL

GRILLGRILL

GRILL TRTR

TRTR

TROUBLESHOOOUBLESHOO

OUBLESHOOOUBLESHOO

OUBLESHOOTING GUIDETING GUIDE

TING GUIDETING GUIDE

TING GUIDE

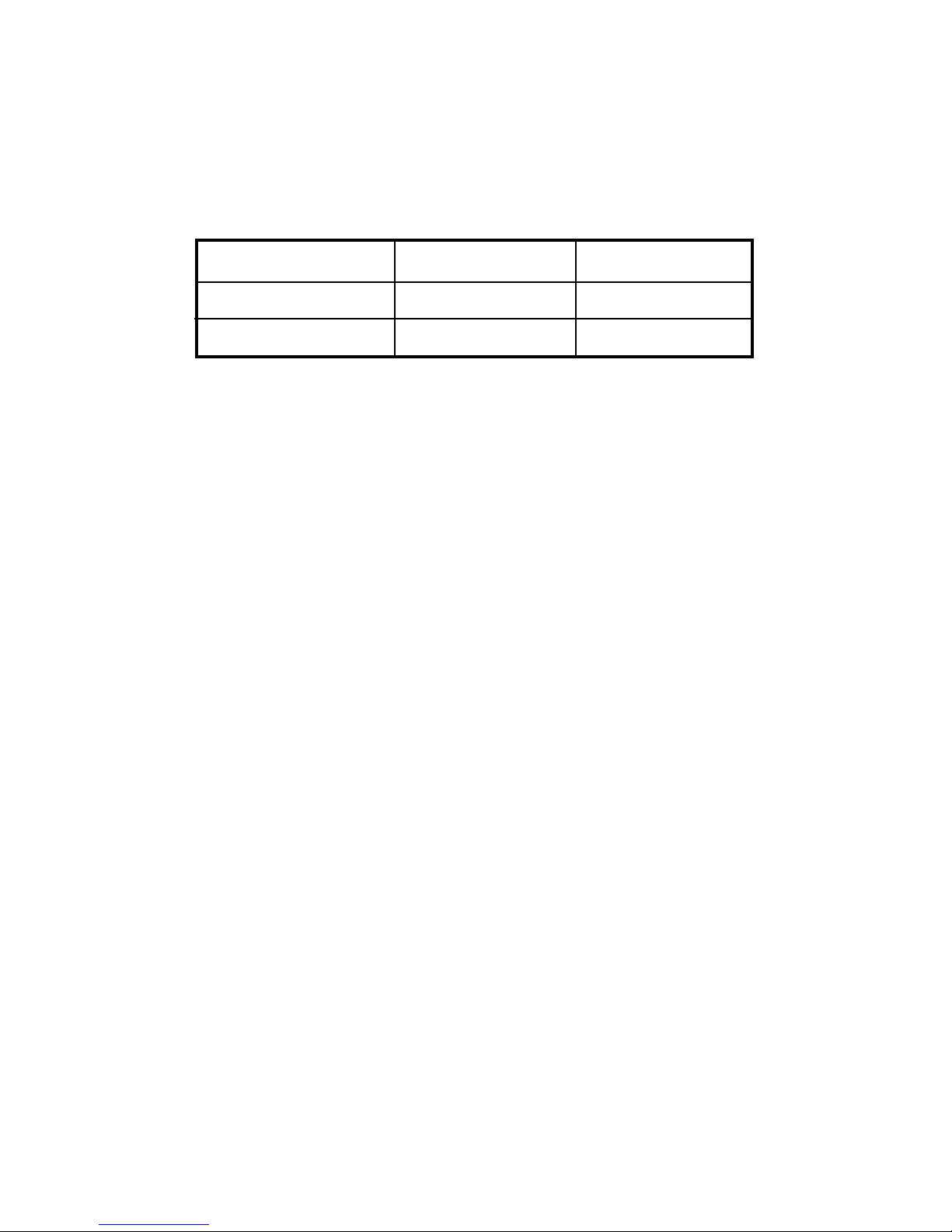

Pilot flame does not

stay lit.

PROBLEM TEST REMEDY

Pilot(piezo-electric)

pushbutton igniter does

not light the pilot flame.

1. Check if igniter is generating a spark.

2. Check for loose spark wire or igniter nut.

3. Check position of electrode 3/16” from

pilotburner tip.

4. Check for dirty/sooty electrode.

5. Retry igniter.

1. Yes - Skip to test #3.

No - Proceed with test #2.

2. Yes - Tighten, skip to #5

No - Proceed with test #3

3. Yes - Skip to test #4.

No - Reposition electrode and

skip to test #5

4. Yes - Clean, skip to test #5

No - Proceed with test #5

5. Lights - Okay.

Doesn’t light - Replace igniter

mechanism.

All service (repairs or part replacement) must be performed by a qualified Service Agency.

1. Yes - Block or redirect the

draft to keep the flame burning

steadily. Skip to test #6.

No - Proceed with test #2.

2. Yes - Adjust the pilot valve

(part of gas control valve) to

increase the flame size, un

screw and retain the slotted

threaded cover; turn the pilot

valve adjustment screw two

turns counter clockwise; re-

install the threaded cover. Skip

to test #6.

No - Proceed with test #3.

3. Yes - Clean. Skip to test #6.

No - Proceed with test #4 .

4. More than 10 millivolts -

proceed with test #5.

Less than 10 millivolts -

replace thermocouple, skip

to test #6.

5. Increase if needed, proceed

with test #6.

6. Stays lit - Okay.

Does not stay lit - Replace gas

control valve.

1. Observe if pilot flame is “wavering” (being

blown about by a draft).

2. Observe if pilot flame is too small to heat

thermocouple.

3. Check for dirty/sooty pilot burner.

4. Check thermocouple output voltage.

5. Check gas supply pressure with all other

equipment operating. (6” WC for natural

gas and 11” WC for propane, minimum)

6. Observe pilot flame.