GB

page 20

INSTALLER SECTION

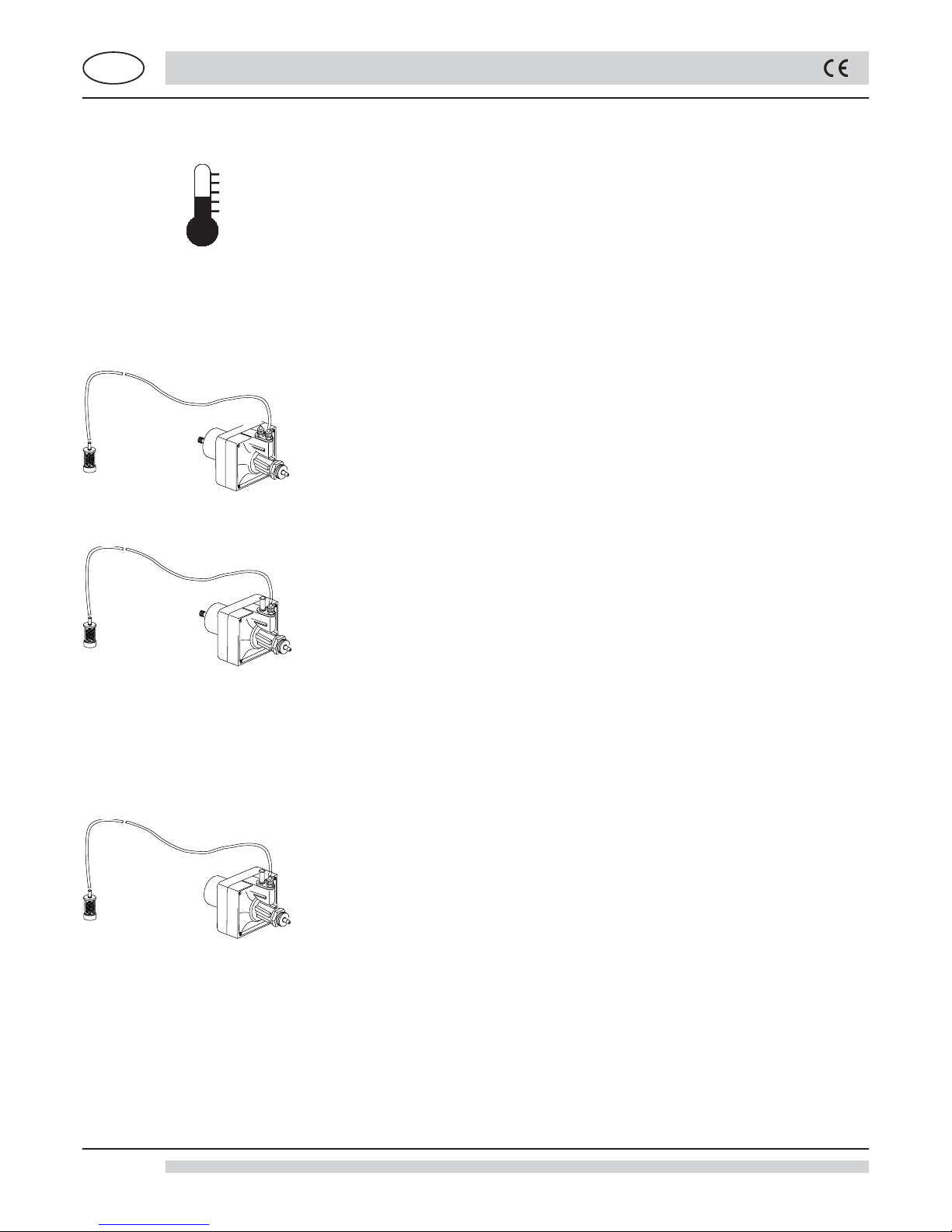

Type B:

code 10599999

C

D

A

B

C

D

B

Type A:

code 10705

C

D

B

A

Type A:

code 10799

1.4 Temperature adjustment

If necessary, the water temperature of the wash and rinse cycles can be adjusted by

means of the fine-adjustment screws on the respective thermostats.

The recommended temperatures are 55° C for the wash cycle (tub) and 85 - 90° C for the

rinse cycle (boiler). Machines with boiler inside the washing tub have only one thermostat

which should be set at 75-80°C.

1.5 Rinse aid dispenser operation

Technical characteristics (type A)

Operation: it utilizes the difference in combined pressure caused by turning the washing

pump on and off, and the rinse pressure.

Water connection:

1) connect the dispenser tube fitting (A) to the pump, by means of the rubber tube installed

in the appliance (pump pressure).

2) Connect the small black rubber tube by the brass delivery fitting (B) to the connection

near the boiler (injector).

3) Make sure that the green product suction tube is inserted on the special fitting (C) and

that the small filter and the ballast are inserted in the rinse aid tank.

Priming: to prime the dispenser, turn on the appliance and carry out several complete

wash cycles or press the adjustment screw D during the wash cycle and open and close

the door combined with pressing the pin D. This method speeds up the refill process.

Adjustment: with each rinse cycle, the dispenser draws an amount of rinse aid, adjustable

from 0 to 4 cc, equivalent to a length of 0 to 30 cm drawn into the suction tube.

In order to regulate the dispenser to the minimum amount, turn the adjustment screw D

completely clockwise. For the maximum amount, turn the screw anticlockwise about 20

complete turns.

For the correct amount of rinse aid, see the paragraph “Use of rinse aid”.(par.5.2).

N.B.: for each turn of the screw the amount of the product drawn into the tube varies by 1.6

cm, equivalent to 0.2 cm³/turn (about 0.21g/turn with a concentration of 1.05 g/cm³ of rinse

aid). The rinse aid cannot function properly if the difference in level between the bottom of

the machine and the container exceeds 80 cm.

Technical characteristics (type B)

Operation: it utilizes the water supply pressure.

Water connection:

1) use the rubber tube installed in the appliance to connect the dispenser fitting (B) to the

special fitting located near the boiler (injector).

2) Insert the green tube on suction fitting (C), with the small filter and relative ballast, in the

rinse aid tank.

Priming: To prime the dispenser, turn on the appliance and carry out a wash and rinse

cycle or press the adjustment screw D repeatedly.

Adjustment: with each rinse cycle, the dispenser draws an amount of rinse aid, adjustable

from 0 to 4 cc, equivalent to a length of 0 to 30 cm drawn into the suction tube.

In order to regulate the dispenser to the minimum amount, turn the adjustment screw D

completely clockwise. For the maximum amount, turn the screw anticlockwise about 20

complete turns.

For the correct amount of rinse aid, see the paragraph “Use of rinse aid” (par.5.2).

N.B.: for each turn of the screw the amount of the product drawn into the tube varies by 1.6

cm, equivalent to 0.2 cm³/turn (about 0.21g/turn with a concentration of 1.05 g/cm³ of rinse

aid). The rinse aid cannot function properly if the difference in level between the bottom of

the machine and the container exceeds 80 cm.