IRONING BOARDS

TV/S TV/SG1F TV/SG2F

ANGHINETTI & CAMPTEL S.r.l

Via XX Settembre 95 - 26040 - Gussola (Cr) Italy

Tel.: +39 0375 / 260885 •Fax: +39 0375 / 260666 •e-mail:

Page 10 of 48 – Rev. 01

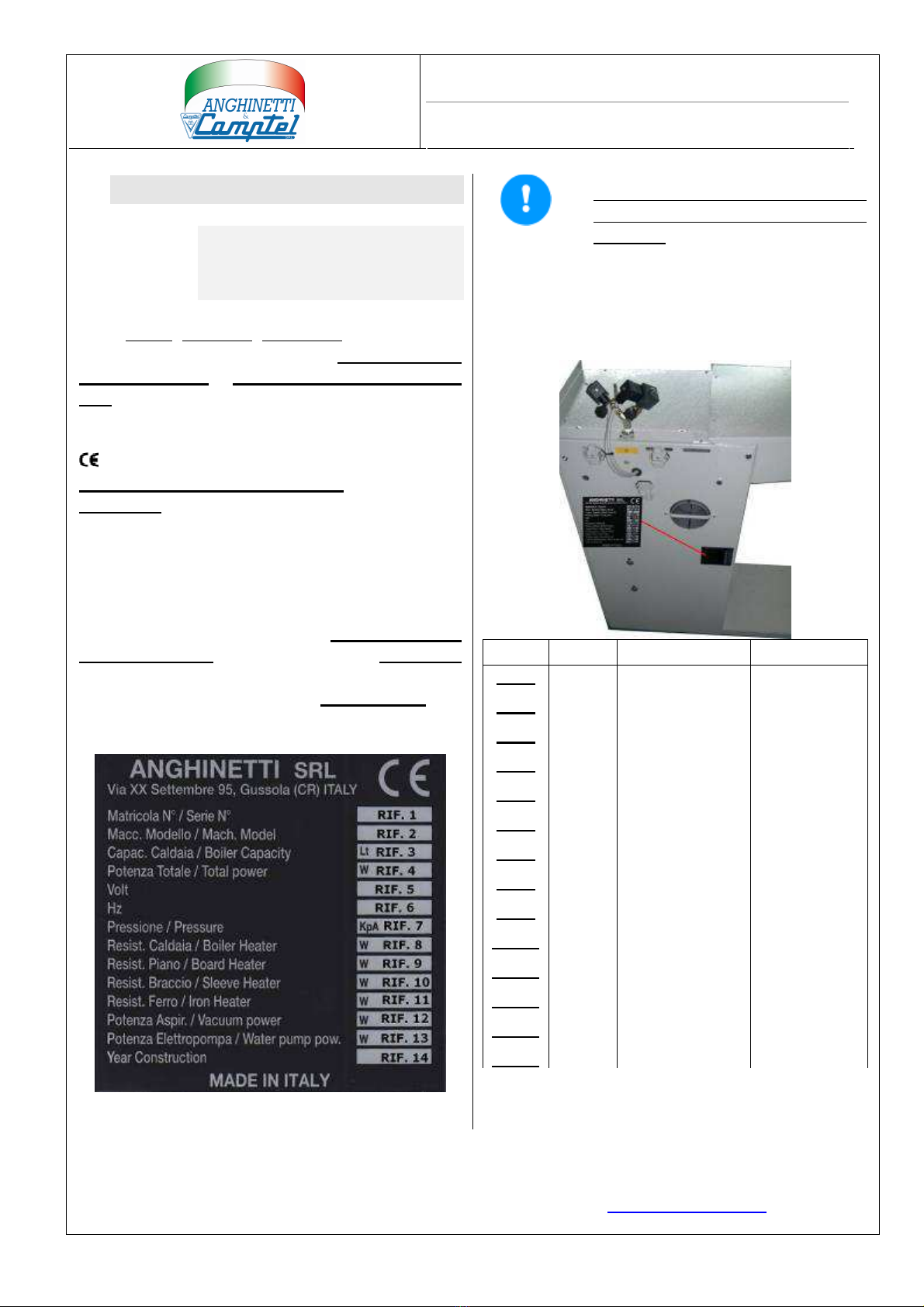

2.2.C

OMMUNICATING WITH

AFTER

-

SALES ASSISTANCE

Use a copy of the specific form attached and always

refer to the following data when contacting the

After-Sales Technical Assistance Service:

Machine type

Serial number

Year of manufacture

ANGHINETTI & CAMPTEL S.r.l

,owner of the

CAMPTEL

trademark, directly assists its products

sold in Italy and Europe.

For any need on use, maintenance or request of

spare parts, the Customer

must contact the

single After-Sales Assistance

Centre or dealer

in your area. Contact the

manufacturing company is you do not know any

after-sales assistance centres or dealers

ANGHINETTI & CAMPTEL S.r.l

Tel. +39 (0) 0375 / 260885

Fax. +39 (0) 0375 / 260666

e-mail: info@anghinetti.com

IN CASE OF ASSISTANCE OR SPARE

PARTS, ALWAYS COMMUNICATE THE

SERIAL NUMBER ON THE

IDENTIFICATION

PLATE

See paragraph 2.1

2.3.G

ENERAL INFORMATION

ON AFTER

-

SALES

TECHNICAL ASSISTANCE

AND MAINTENANCE

Check any malfunctioning does not fall within the

operations described for “

scheduled

maintenance” (refer to paragraph 7.5

); on the

contrary, contact the Manufacturing company's

After-Sales Assistance Service.

The non-compliance with

chapter 7

maintenance

, lifts

ANGHINETTI & CAMPTEL

S.r.l

,from any responsibility in case of personal

injuries and/or damage to property and machine

operation faults.

2.4.W

ARRANTY TERMS

The Warranty on Machine Components has a

12

month

validity on any mechanical, electric,

electronic, pneumatic and hydraulic part with an

eight-hour day of operation, starting from the data

on relative

Delivery Note

. Said period is halved

for more severe working conditions.

The Warranty only includes replaced parts,

excluding labour

.

As long as the machine is used in accordance with

the Manufacturer prescriptions (installation, use,

maintenance and performance limits) the

Manufacturer commits to supply the faulty pieces

or parts for evident manufacturing vices under the

warranty period, free of charge, within minimum

technical times and ex works.

The Customer will be charged with transfer,

shipment, labour costs and anything else is required

for replacement. The Manufacturer will be

responsible for the costs of the replaced piece.