WordClock-4 Assembly Guide 05/15/21 Version 0.8

Page 4

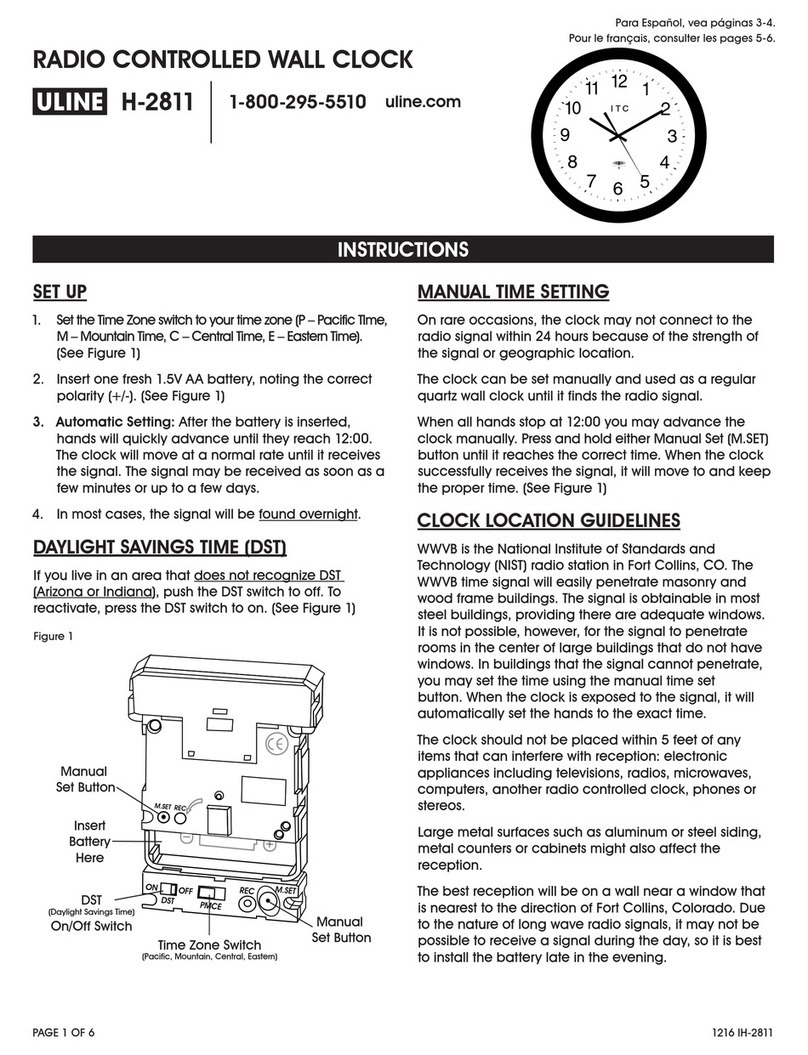

• Install one or two TaylorEdge 1363 high voltage power supplies with the coils facing the

word, “COIL” on the board. If only one power supply is used, connect a jumper between

HVJP1 and HVJP2.

• There is no load balancing facility available so do not connect this jumper if two

power supplies are used.

Connect the 12V power supply. Both neon bulbs should now be lit. Check one or both

+170V test points for approximately +170V.

If the voltages check out and the neon bulbs are lit, remove the power supplies and the

ENABLE jumper.

• Install the components on the bottom of the board, starting with the surface mount

resistors. Note that each “00” series is the same value, for ease of assembly.

• Install the surface capacitors, followed by the ICs. The line or dot on one side of each

chip must be installed toward the cutout on one side of the silkscreened pattern. The

best way to install a surface mount chip is to add a very small amount of solder to one

of the corner pads on the board. Then quickly and carefully solder the corresponding pin

to the pad. Check the alignment of all pins and if correct, solder the opposite corner pin.

Check the alignment again, then solder the remaining pins quickly and carefully. Always

use a magnifier to check for solder bridges and bad solder joints. The HV5530s are very

difficult to solder successfully and must be checked with magnification to ensure that

each pin is soldered, and that there are no solder bridges. Use solder braid to easily

remove solder bridges.

• Install the SD card connector next. Be sure to solder all leads to the board. Solder quickly

and carefully. The plastic chassis can easily be damaged by too much heat. Several pins

on one side of the connector are very close to the grounded case. They do not need to

be soldered. Then install J3, the GPS connector.

• Install all of the remaining parts on the top of the board. Note that the APA102 RGB LEDs

must be installed with the cutout facing the dot on the board.

• The ambient light sensor, Q2, should be installed about 10mm above the board. The

shorter lead goes toward the back of the board.