5

Dataofconnection tothe energysupplysystem

ATTENTION!Installation ofthe equipment, itsconnection tothe electric-resp.steam

networksmaybe performed byaspecialist fitter ofthe given area.

Connection of the electricpower

Type Voltage,

current type

V, Hz

Class of

shock

protection*

Power consumption

W

fan heater

Mainfuse**

A

PRAKTIK 3x400/230, 50 I. 550 1000+100 3x10

COMPACT 3x400/230, 50 I. 550 1000+280 3x10

*- Wired shockprotection accordingtoEN 60204-1(6.3.3.; 8.)

**- Safety-fuse or small circuit breaker of"L"-characteristic

•All type ironingtables,on aspecialorder, can also be delivered withfan of230 V,50 Hz

or 3x400V50 Hzvoltage, 370 Wfan motor.

•The equipmentisdelivered completewithwiringprepared forconnection.Afterbeing

connected tothe mains the equipment isserviceable.

-The connection iseffected withuse ofconnectorplugprovided withprotection contact,

withuse of3- resp. 5-conductor power cable.

-The voltagedrop on the mains installed forthe connectorplugshouldnotexceed +/-

10 %.

-The wall outlet socket shouldbe provided withan independent isolation switch.

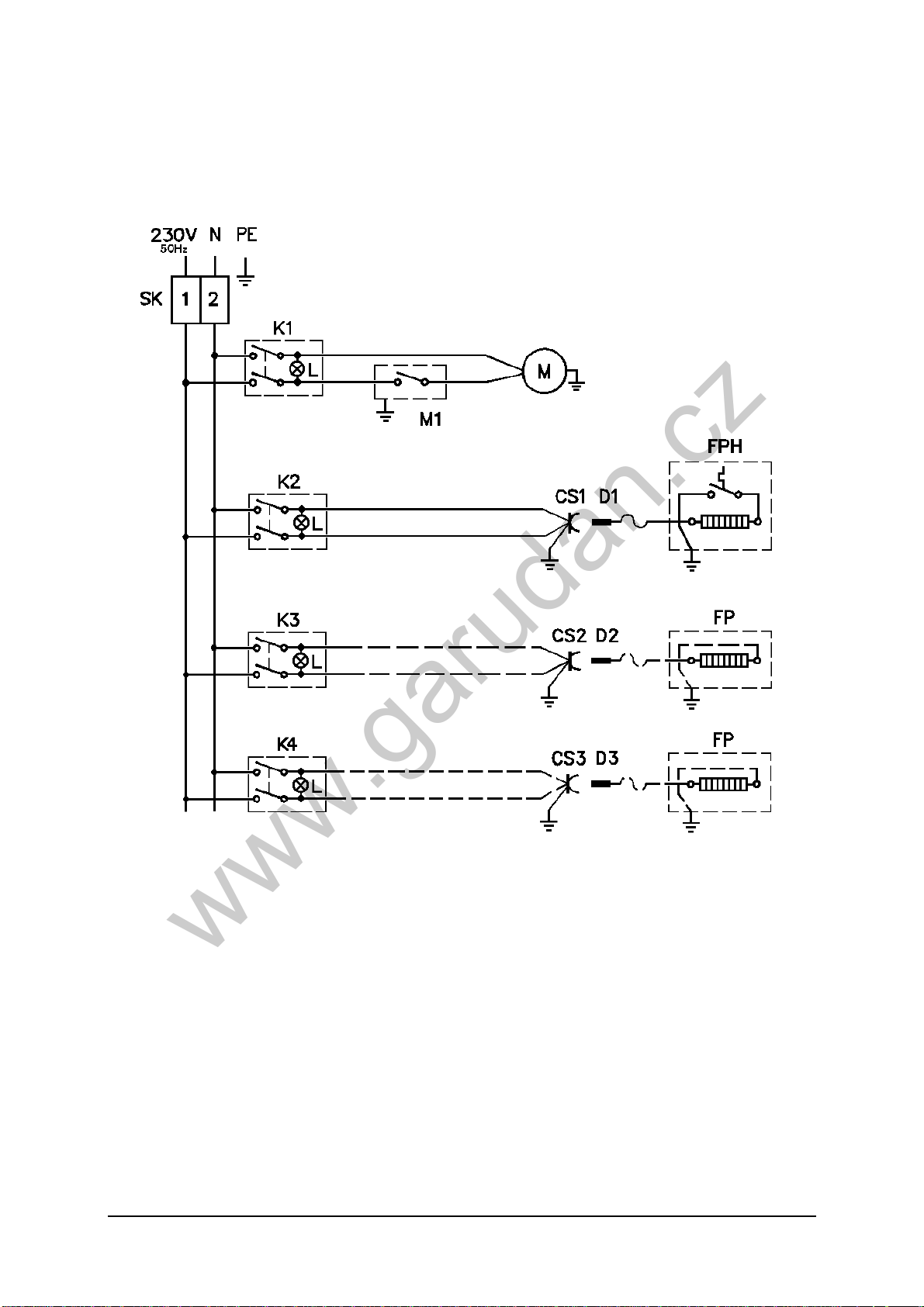

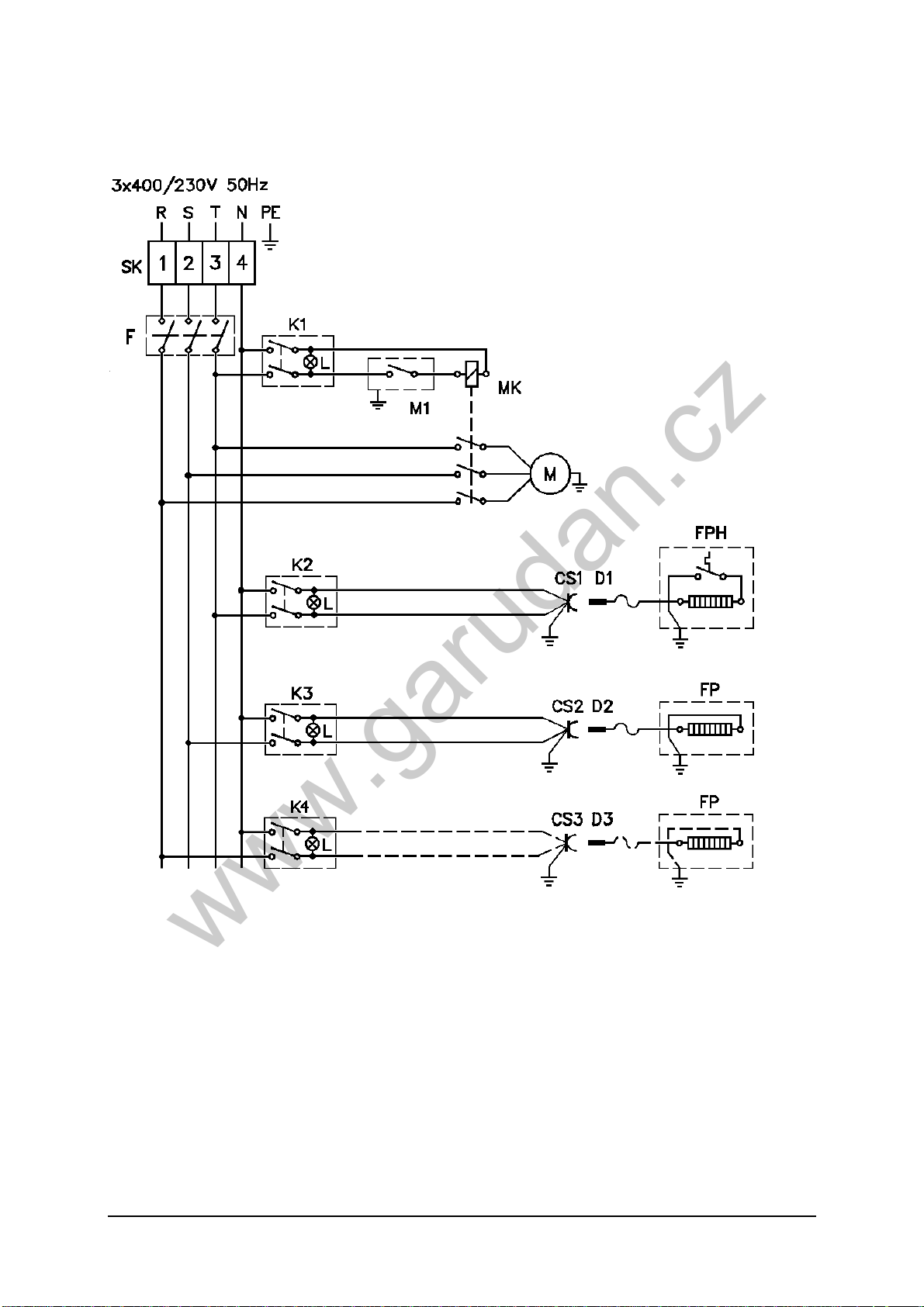

ATTENTION!The electricconnections havetobe established accordingtothe schematic

circuit diagram.

Connection ofthe equipmentispermissibleonlytoamains provided with

wired shockprotection.Shouldthe equipmentgetfaultydue tobeing

operated fromamains notprovided withadequateearthingthen the

resultingdamages will be bornbythe operator.

The connection has tobe made inafullyde-energized stateofthe

equipment.

Preventive measures required on behalf of the operator:

•Checkingthe shockprotection systemofthe equipmentaftercommissioning,resp.

repairs.

•Removingcombustible-inflammablematerialsfrom the vicinityofthe equipment.

•Providingindividualprotection devices (gloves)forcontrolsofthe equipment(fittings

outside the cover) whose operatingtemperaturemayexceed 50 oC.

•Coveringthe top ofthe equipment, storingforeignobjectson it isPROHIBITED!

•DO NOTleavethe equipment unattended duringitsoperation!

•Incase ofabreaklonger than 15 minutes the equipment has tobe switched off.

•Incase ofbreakdownthe equipment has tobe switched off.

c)Datarelating tothemachineitself

Operatingtemperatureofthe pad (as measured on the perforated plate): 90 - 120 oC

Operatingtemperatureofbase pad withcontinuous control: 25 up to120 oC.

Steam demand for ironing: withiron, approx. 2kg/h

Steam pressurefor ironing: 3- 6bar, dependingupon technology

The operatingnoise levelofthe equipment islower than 70 dBA sound pressurelevel.