General Information 1-4 Replaceable Parts

MS27102A MM PN: 10580-00420 Rev. A 1-3

1-4 Replaceable Parts

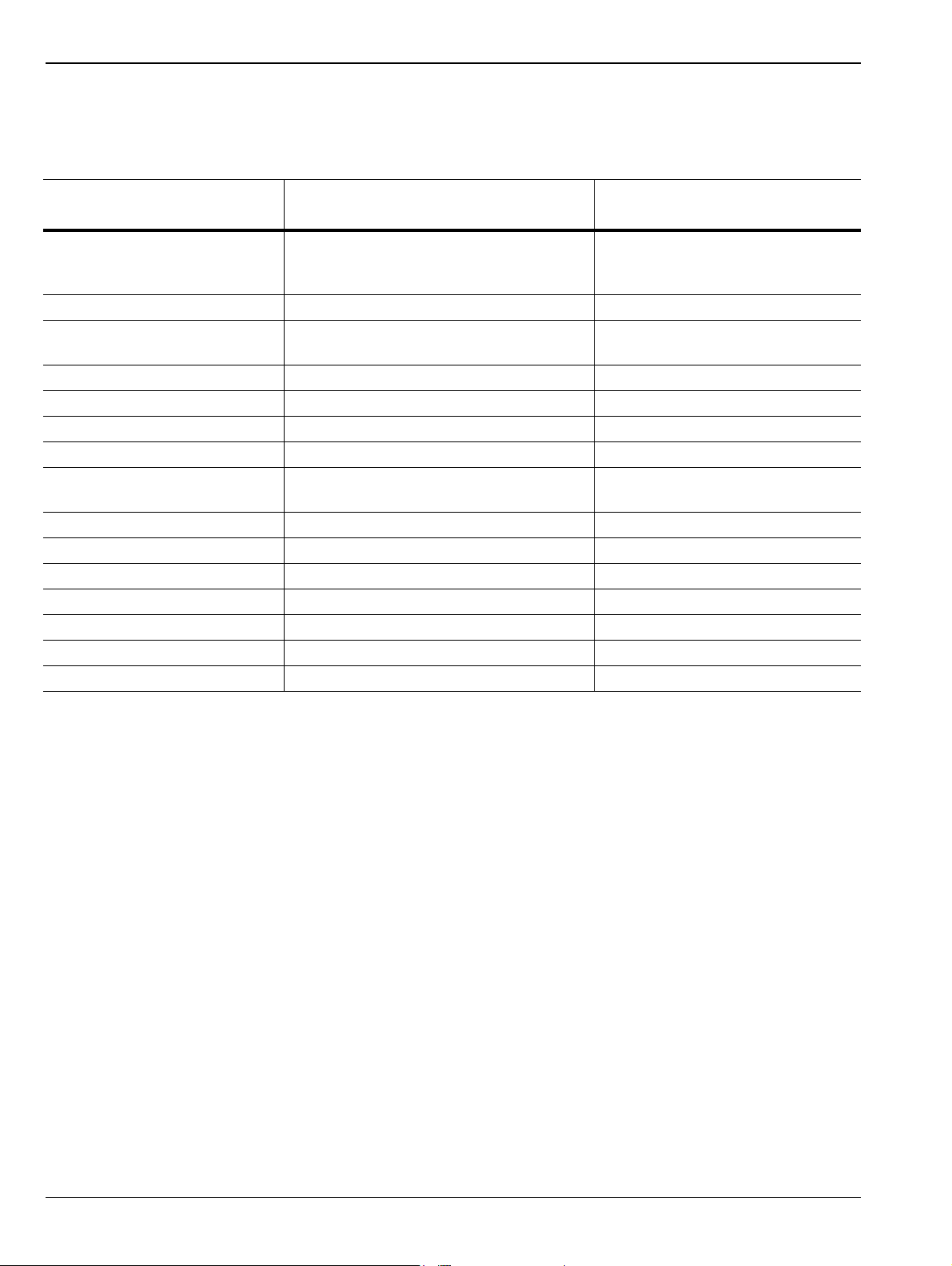

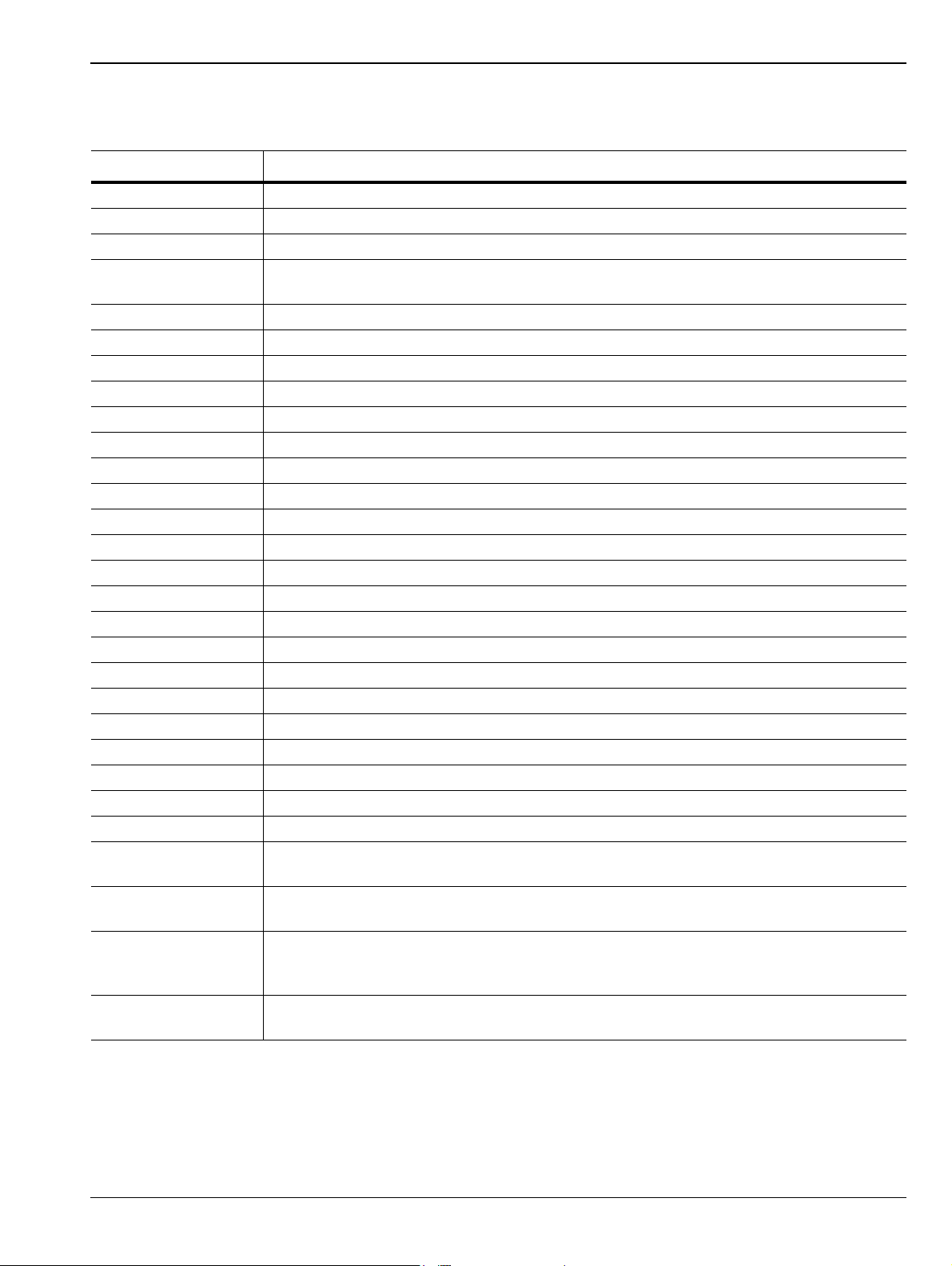

Table 1-2. List of Replaceable Parts

Part Number Description

ND82026 Main PCB Assembly

ND82027 MUX PCB Assembly, for 2-port instruments

ND82030 Main/MUX PCB Assembly, for 2-port instruments

3-2000-1828 IP67 Chassis

(includes top and bottom covers, plugs, internal Ethernet, DC and GPS cables)

3-790-775 IP67 Top Cover

3-790-774 IP67 Bottom Enclosure

3-790-777 RF Port Plug (single plug on back of bottom enclosure)

3-513-140 RF In Port, N(F) to SMA(F) Adapter

3-75261-5 10 MHz Reference Cable (BNC to MCX)

3-806-328 GPS Cable (SMA to MCX)

3-806-326 DC Cable (Connects SPA to DC connector on chassis)

3-81592 Port 1 to SPA Cable, for 1-port instruments

3-81593 Port 1 to SPA Cable, for 2-port instruments

3-81594 Port 2 to SPA Cable, for 2-port instruments

3-81591 SPA to MUX Cable, SMA to SMA, for 2-port instruments

3-67367 SPA to MUX Interface Cable (USB Type A to 1x5)

3-81597 EMI Foam Block, 120 mm x 265 mm x 31 mm, for 2-port instruments

3-806-327 Ethernet Cable Internal, 200 mm

3-553-560 Cap with Chain, N(F) Cap

3-553-561 Cap with Chain, SMA(F) Cap

3-81341 Bracket for BNC Connector of 10 MHz Reference Input

3-81599-1 Conductive Foam, 152 mm x 15 mm x 15 mm

3-81599-2 Conductive Foam, 228 mm x 15 mm x 15 mm

3-790-780 Bracket, External Mount for IP67 Chassis

3-81595 Mounting Bracket Extension Set for IP67 Chassis

3-553-559 CAT6 Cable Seal for cable OD 4.5 mm to 6.5 mm. Includes seal nut, clip, seal, body, and

gasket. Allows sealed connection to IP67 chassis

3-553-558 Seal for cable OD 6.6 mm to 8.6 mm. This is seal only and replaces seal from 3-553-559.

If nut, clip, body, and gasket are needed, order both 3-553-558 and 3-553-559.

3-510-155 Power Connector Housing. Includes seal nut, clip, seal, body, locknut, housing, and

O-ring. This allows the input power cables to be connected to this part, and then

connected to the IP67 chassis.

3-553-557 CAT6 Module, without internal jumper. This is the internal RJ45 connector allowing an

external Ethernet cable to connect to the IP67 chassis.