7. The left most trim is used to balance the cathode voltage

8. Start by first adjusting the plate balance, then the cathode balance trim for

minimum meter deflection.

9. Output gain fully clockwise (zero attenuation)

10. Repeat step 8. Note meter indication.

11. Adjust the plate balance trim slightly clockwise until a change in meter indication is

observed. Then adjust cathode balance for a meter indication less than that noted

in step 10.

12. If meter indication is less than that noted in step 10, perform step 11 repeatedly

until absolute minimum meter indication is obtained.

13. Once the balancing procedure is completed, detach the 3-VAC ( 3-VAC test 3--J )

cable, replace top and resume recording.

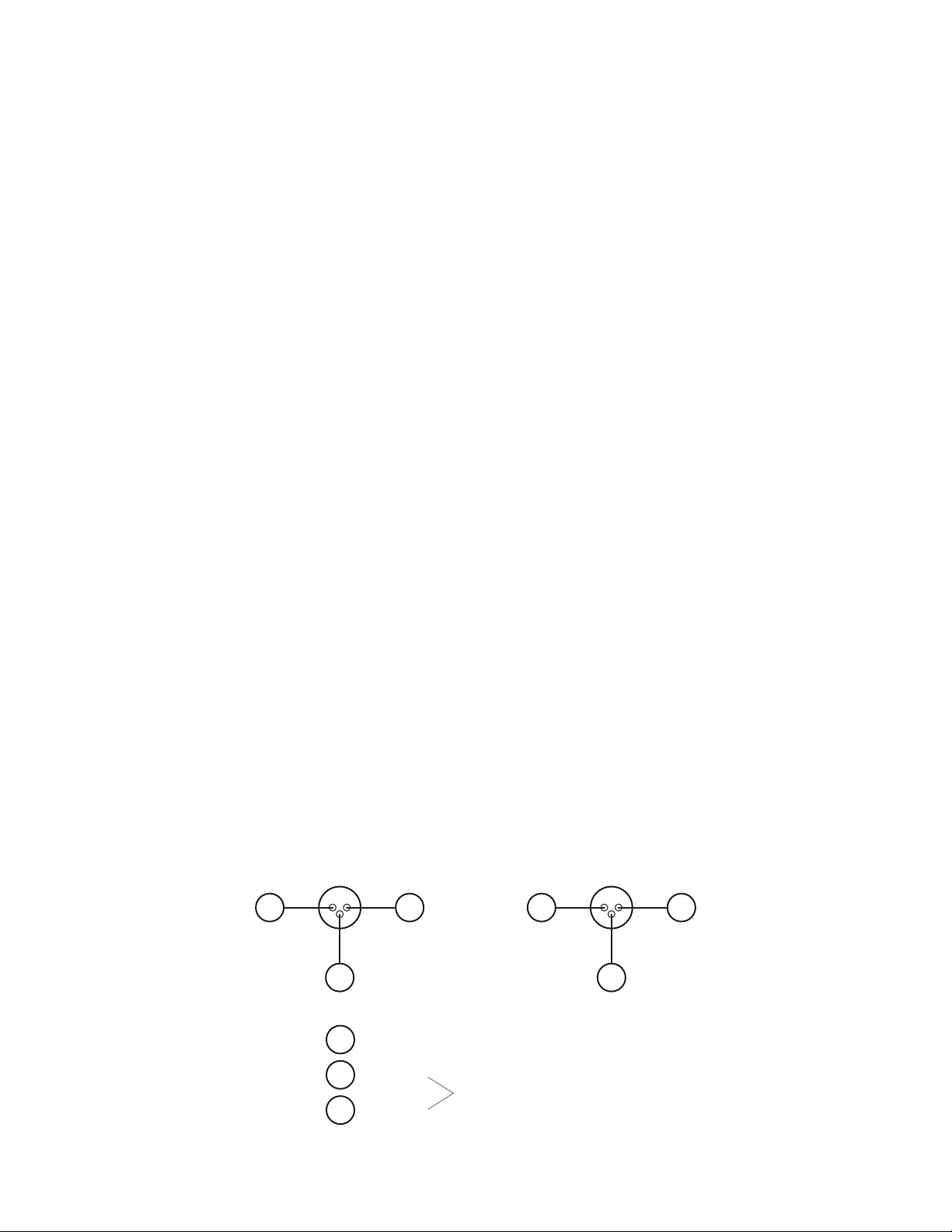

14. 6BC8 / 6BZ8, If this tube is changed or fails, it will effect meter reading requiring

new GR meter adjustment

Please note: A minimum meter deflection of -20 dB will yield the best performance. If the

two sections of the 6BC8 (high frequency twin triode) are not reasonably symmetrical,

the tube will be noisy and cause a thumping sound when in compression. In the event

that the balancing procedure does not yield a usable tube, it must be discarded and

repeat balancing procedure with a new tube.

Specifications

Frequency Response

Clip

Distortion

Noise

Input/Output Impedance

Dimensions

Fuse

Tube Compliment

Shipping Weight

Power Consumption

7

. . . . . . . . . . . . . . . . . . 10 Hz ------ 30 K hz

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +28 Dbu

. . . . . . . . . . . . . . . . . . . . . . < 0.1% --10-GR =< 0.5%

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . --75 Dbu

. . . . . . . . . . . . . . . . . . . . . . . . 600 ohm

. . . . . . . . . . . . . . . Standard 19” 2-U depth 11-1/8”

. . . . . . . . . . . . . . . 120-V . . . . 2-Amp Slow Blow 5x20mm

220-V . . . . 1-Amp Slow Blow 5x20mm

. . . . . . . . . . . . . . . V--1 6BC8, V--2 12AX7A

V--3 12BH7A/12AU7A, V--4 6CL5

. . . . . . . . . . . . . . . . . . . . . . . . . 13 lb. or 15 Kg

. . . . . . . . . . . . . . . . . . . . . . . . Watts 28-W