Antti-Teollisuus Oy 6 408099 11-2020

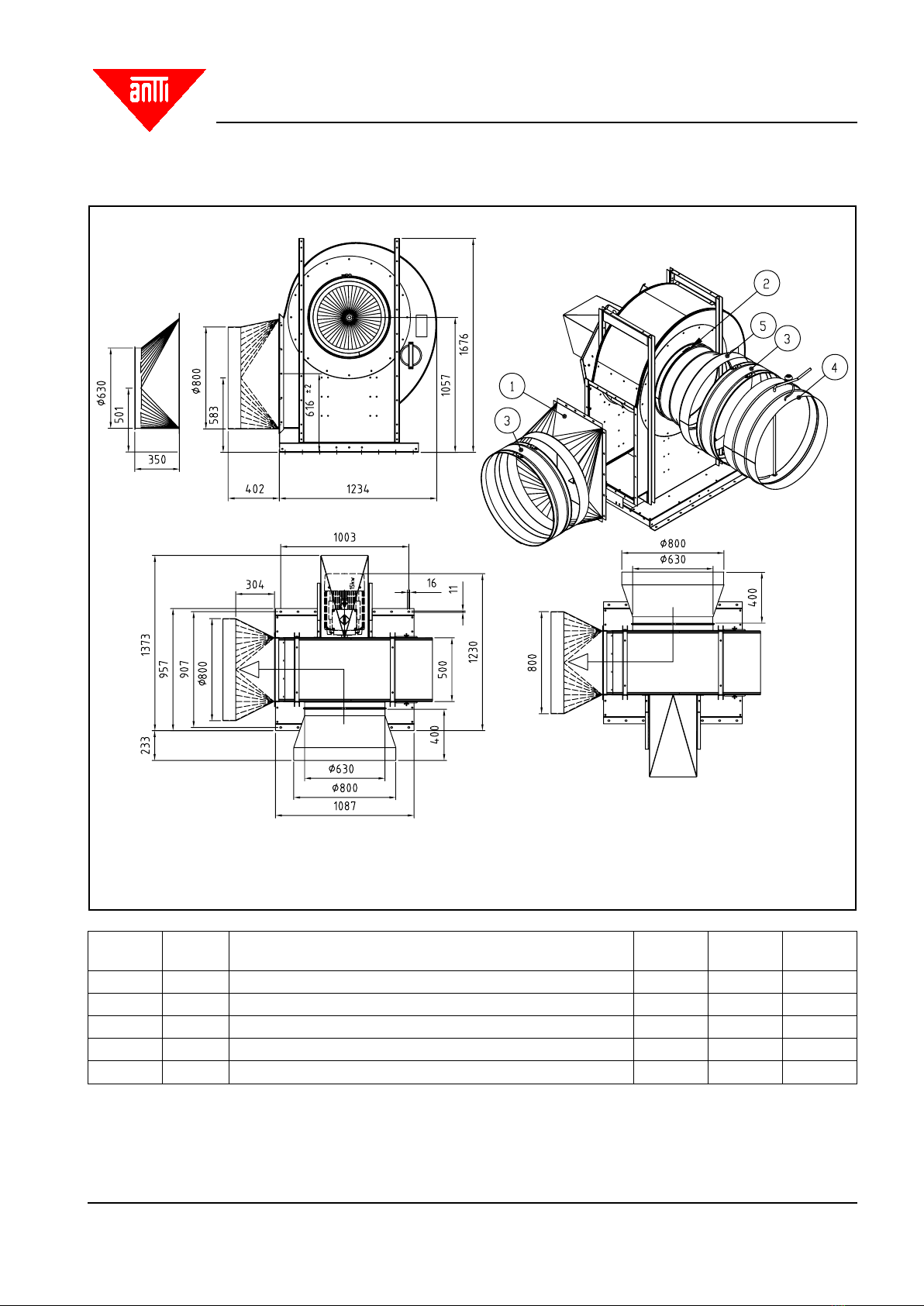

Blower units and axial blowers

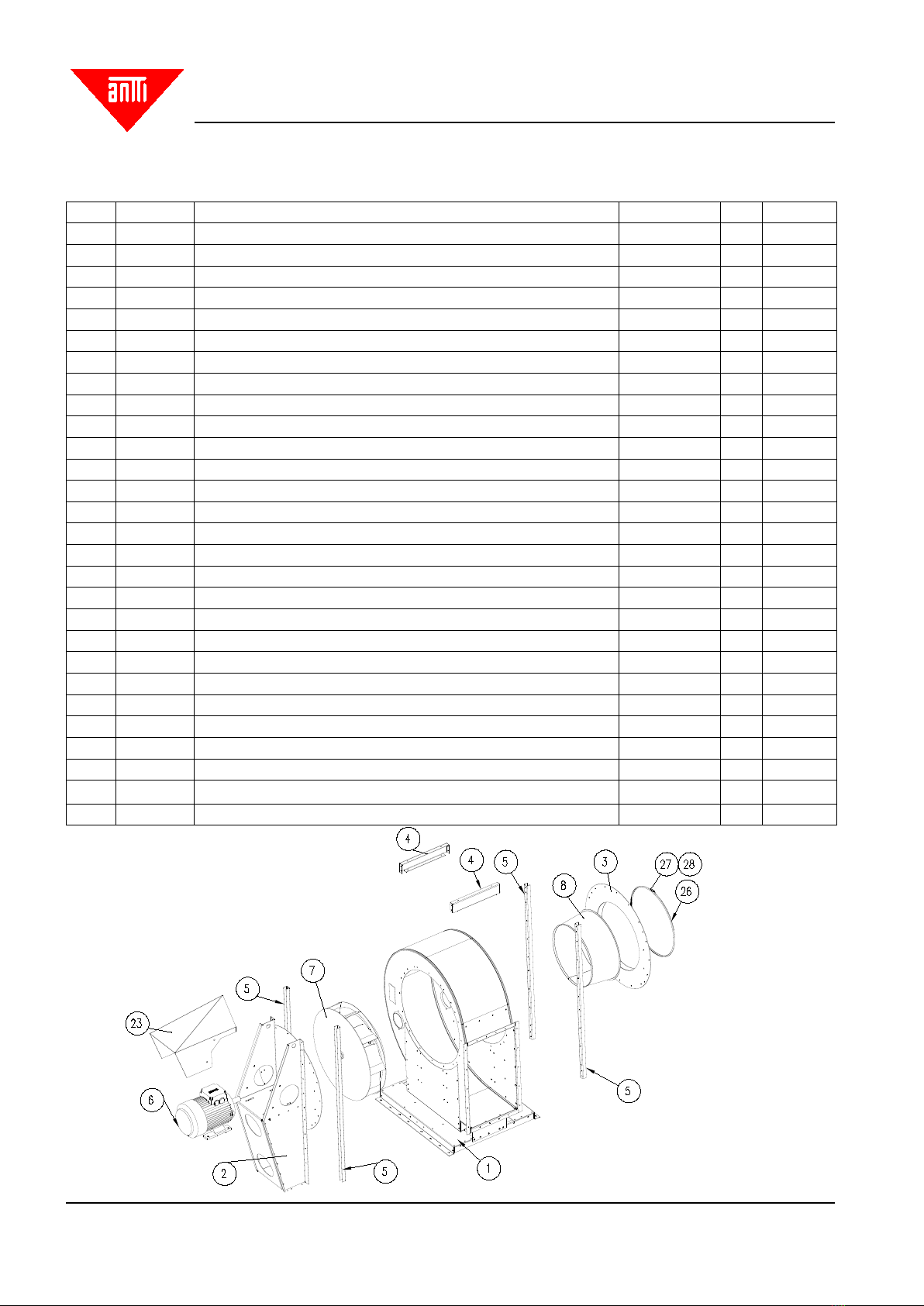

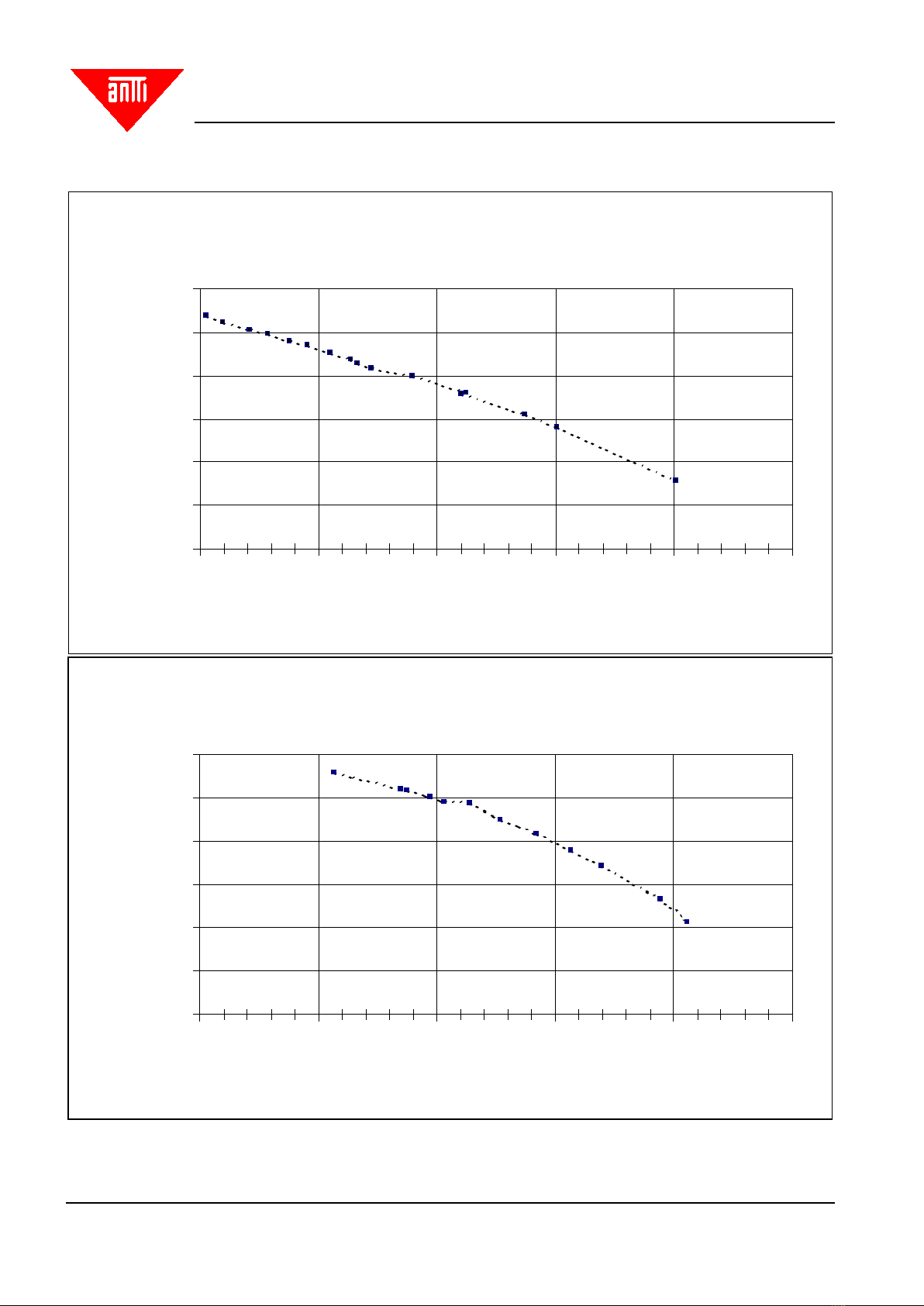

SPARE PARTS DRAWING 15 kW

Part Item Denomination Drawing No. Pcs. Weight

1 A71860 BLOWER A400 SUB-ASSEMBLY A71738-0 1 104,45

2 A71897 BLOWER A400 MOTOR RACK ASSEMBLED A71897-0 1 53,87

3 33407 BLOWER A400 SUCT CH ATTACH ASSY ROUND 33407-0 1 11,42

4 A71140 DR HEATER BLOWER HOUS A400 FRAME SUPP M03 A71140-0 4 1,91

5 A71141 DR HEATER BLOWER HOUS A400 REP K SUPP M03 A71141-0 4 3,90

6 303524 MOTOR 15,00 KW 1500R B3 303524- 1 120,0

7 22476 ROTOR STANDARD B840/167 15KW 22476-B 1 38,90

8 31560 DR HEATER BLOWER A400 SUCT CONE D624/576 31560-A 1 6,43

9 41560 HATCH D170+HOLDER 41560-0 2 0,46

10 117911 PLATE STICKER 25x50 THT-17-434-3 0 1 0,00

11 400342 WASHER PL5 D 52/13 0 4 0,08

12 102573 HEX BOLT M12x50 DIN931 0 4 0,00

13 111560 WASHER ZN M12 ZN DIN 125 0 4 0,00

14 112320 LOCK WASHER M12 (112320) DIN 6798A 0 4 0,00

15 110570 NUT M12 DIN934 0 4 0,00

16 101860 HEX BOLT ZN 8x35 DIN933 0 4 0,00

17 110540 NUT M8 DIN 934 0 120 0,00

18 117774 PLATE STICKER, DANGER FROM ABOVE 0 2 0,00

19 400340 WASHER PL5 D52/17 - 1 0,07

20 112320 LOCK WASHER M12 (112320) DIN 6798A 0 1 0,00

21 103011 HEX BOLT M16x60 DIN931 0 1 0,00

22 117920 PLATE ARROW 117920-0 1 0,00

23 A71172 RAIN COVER PLATE A-400 11/15 KW M03 A71172-C 1 6,48

24 101820 HEX BOLT ZN 8x20 DIN933 0 112 0,00

25 503015 DR HEAT BLOW A400 INTERM SLEEVE D56-11 41301-2 1 0,09

26 504591 AIR DUCT BAND D625 A71000-0 1 0,52

27 104243 BOLT HEX SOCKET 6X70 AM 0 1

28 110530 NUT M6 DIN 934 0 1 0,00

Spare parts drawing, 11 kW and 15 kW