PNEG-1984 Page 3 of 4

Bio-Dri II™ Air Inlet Door Assembly Instructions

Inlet Door Adjustment Instructions

1. Prior to adjustments the linear actuator must be wired up tothe PLC panel and capable of operation.

Please refer to Air Inlet Door Actuator wiring diagram. Once wired up, the two (2) dial switches on

the controls on the outside of the PLC panel can be used to operate the linear actuator. One dial

switch is used to go between Auto, Off and Hand (Manual). When in Manual mode, the other dial

switch has two (2) operating positions: Purge and Re-Cycle. When in Purge, the linear actuator will

attempt to extend a full 24'' until the internal limit switch shuts it off. When in Re-Cycle, the linear

actuator will attempt to retract until the external limit switch shown in Figure 3 on Page 4, shuts

it off.

2. Change the switch position on the outside of the PLC panel to manual Mode/Purge and let the

linear actuator extend the full 24'' until the unit comes to a stop. There will probably be a 1'' to 2''

gap remaining between the door and the framing in the Purge position. Remove the eight (8) plastic

plugson topofthe linearactuatortoprovide accesstotheallen headscrewsunderneath.Loosen all

eight(8) allenhead screwson topof theactuator with a 6mm allen wrench(P) not provided.Loosen

each screw approximately 5 complete turns.

3. Rotate the door counterclockwise slightly, until the 1'' to 2'' gap between the door and the framing

in the Purge position is closed up. As the door is rotated, the linear actuator will slide inside the

housing to the correct adjustment position. Tighten the eight (8) allen head screws securely.

Replace the eight (8) plastic plugs in the top of the linear actuator.

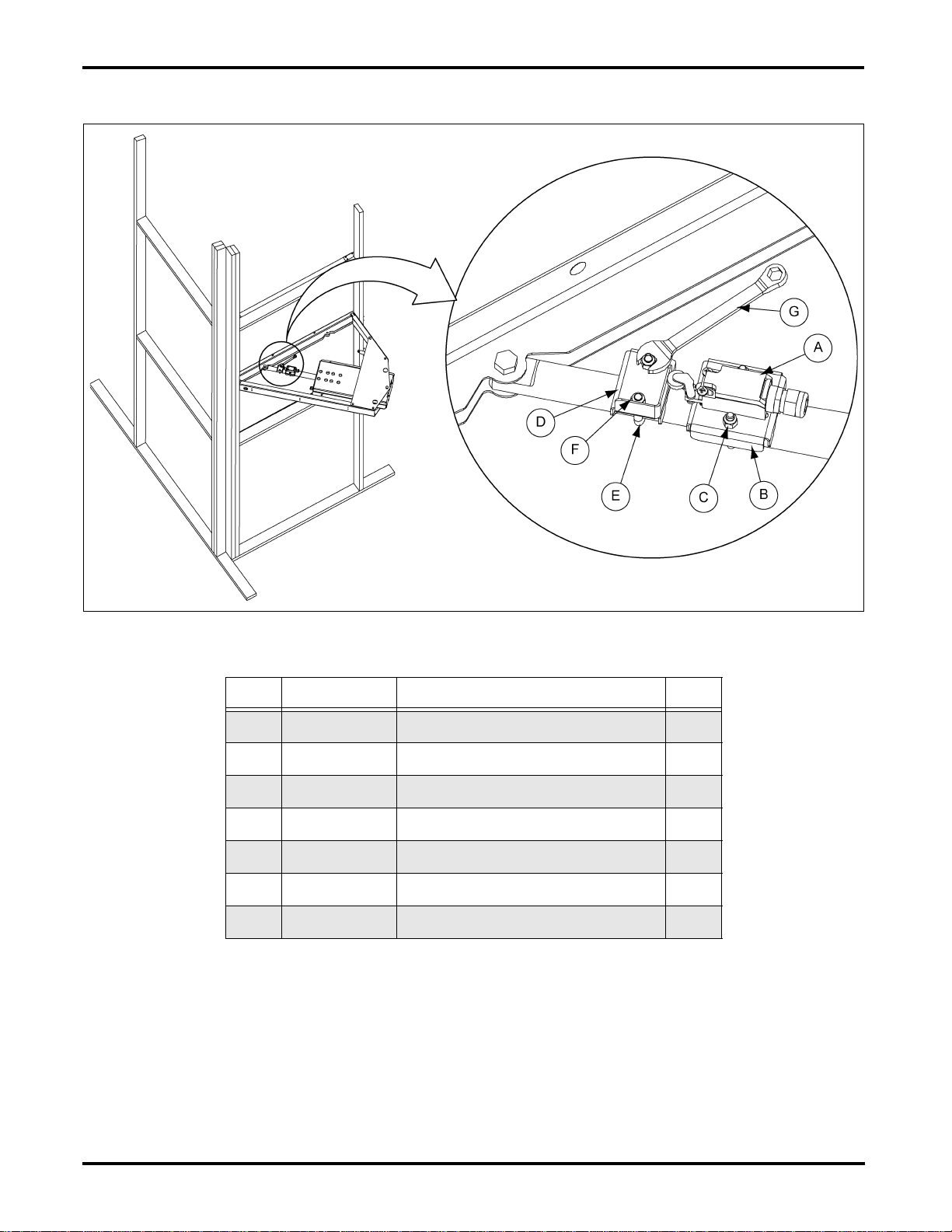

4. Refer to Figure 3 on Page 4. Change the switch position on the outside of the PLC panel to

Manual/Re-Cycle and let the linear actuator retract until the external limit switch (A) strikes the

actuator bracket (D) and the unit comes to a stop. There will probably be a 1'' to 2'' gap remaining

between the door and the framing in the Re-Cycle position. Change the switch position on the

outside of the PLC panel from manual to off.

5. Using a 1/2'' Wrench (G), loosen the nylock nuts (F) on the U-Bolt (E) and slide the actuator

bracket(D)forward towardstherodend ofthelinearactuator approximately1/4''.Tightenthe nylock

nuts (F) on the U-Bolt (E). Change the switch position on the outside of the PLC panel from Off to

Manual. The linear actuator will retract slightly until the external limit switch causes it to shut off.

Ensure that the 1'' to 2'' gapbetween the door and the framing in the Re-Cycle position is closed up.

If not, repeat this step until the door gap is closed.

6. Change the dial switches on the outside of the PLC panel to Auto/Re-Cycle. The inlet door is now

ready for normal operation. In normal operation, when the Bio-Dri II™ is not running, the inlet door

should remain in Re-Cycle position in order to keep birds and debris from entering the air mixing

chamber. When the Bio-Dri II™ is in Pre-Bake mode, Bake mode or Post Bake mode, the inlet door

should be in Re-Cycle position in order to allow the hot air to Re-Cycle through the system. The only

time the inlet door should be in Purge position, is during the 8 minute purge time at the end of the

cycle, in order to clear out deadly gas fumes and quickly cool the room down, prior to safe entry.