CMD Ltd, Rotherham, S65 1EN, UK

‘CLICK’

Additional information

• Installation is to be carried out in accordance with relevant Health & Safety regulations and only to be carried out by a skilled or competent person.

• It is recommended that oor boxes are not installed in high trafc areas.

• The installation should be installed to comply with the relevant national standards and be inspected and tested prior to being put into service

(in the UK BS 7671).

• Isolate the supply before installation or repositioning. Any locking mechanisms must be used and fully engaged.

• Incorrect use could lead to risk of electrocution.

• Product to be used only for the intended purpose of distributing power in a commercial environment.

• Do not misuse, dismantle or re-congure the product because doing so will invalidate the warranty.

• If a product incorporates RCD protection, the RCD should be regularly tested in-line with current standards.

Safety

• Refer to the Declaration of Conformity.

• If viewing this sheet prior to specication/technical documentation purposes, be aware of potential plug clashes with certain socket plate orientations.

Standards

• Clean using a dry cloth. No abrasives or solvents to be used on the product. Do not drop or expose to moisture.

Product care

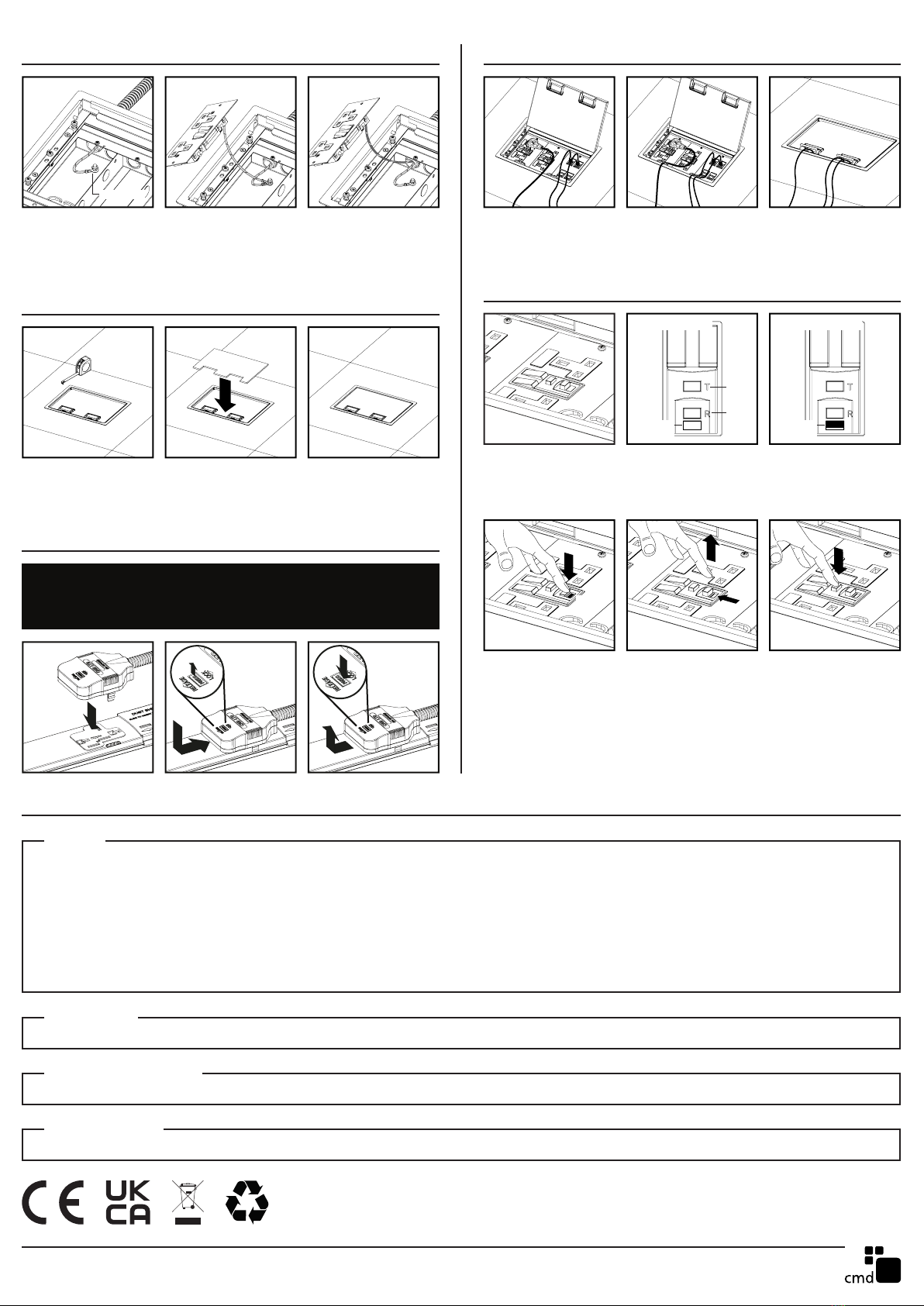

Tap-off engagement/release

**WARNING**

An unterminated tap-off MUST NEVER be connected to a live track.

Provided that it is off load, a terminated tap-off may be removed/

inserted into a live track. Conduit must be bonded to Earth.

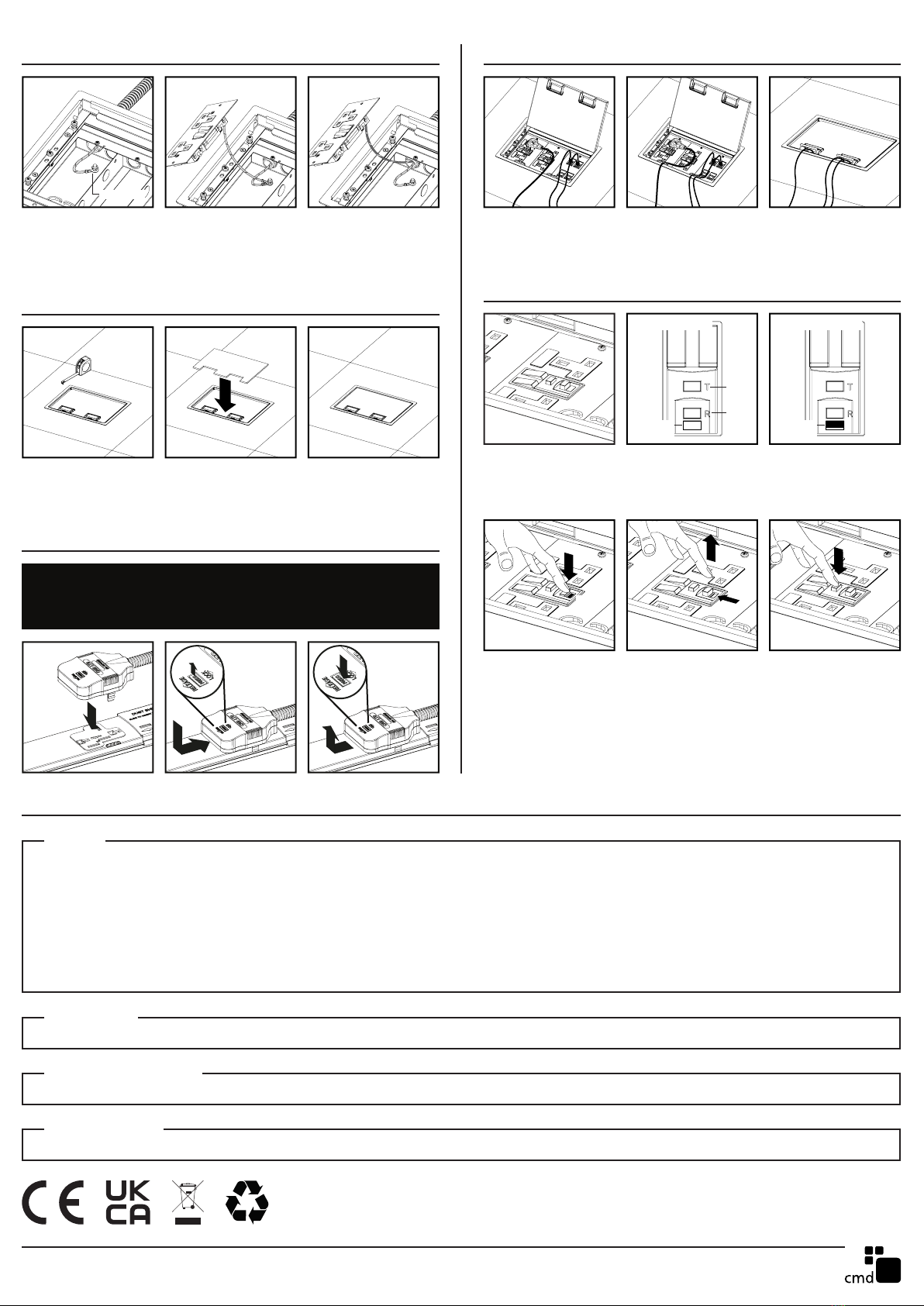

To reset after it has

tripped, press and hold

the grey reset button

until a click is heard.

The indicator will change

to show it is now active.

Remove your nger from

the reset button.

A qualied person

should test the SRCD

function periodically to

comply with standards.

A qualied or fully

competent person

should test the SRCD

before rst use.

Plug any power and

data cables into their

respective sockets.

When active, the SRCD

indicator window is

lled with a red marker.

If possible, try to keep

power and data cables

segregated when using

the cable guides.

When the SRCD trips,

the red marker in the

indicator window

recedes as shown.

Carefully close the lid

and ensure the cables

are fed out through the

cable access brackets.

Testing and resetting SRCD socket (if applicable)

Cable management

‘CLICK’

Test

Reset

Indicator

up

Indicator

down

Active SRCD state Tripped SRCD state

Measure the inside

dimensions of the lid.

Carefully cut out the

shape from the desired

material substrate

(carpet, tile etc.)

Fit the inlay into the lid

and secure with suitable

bonding agent.

Fitting the lid inlay

Earthing the box and sockets

Earth stud

Standard Earth Clean Earth (C/E) Low Noise

The box base must be earthed with a suitable ring terminal to the integrated

earth stud. To ensure the sockets are earthed, a link will be required from

the box earth stud to the socket earth. On Clean Earth (C/E) Low Noise

installations these should be wired directly to the Clean Earth CPC (Circuit

Protective Conductor).

Further guidance