2

ATEX –Duct Smoke Detector

Content

Content

..................................................................................................................................................................2

1

Introduction

........................................................................................................................................................4

2

Aboutthisdocument

.......................................................................................................................................5

2.1

Objectives and intended readers

.............................................................................................................5

2.2

Symbols used

................................................................................................................................................5

3

Safety

....................................................................................................................................................................6

3.1

Guarantee claims

.........................................................................................................................................7

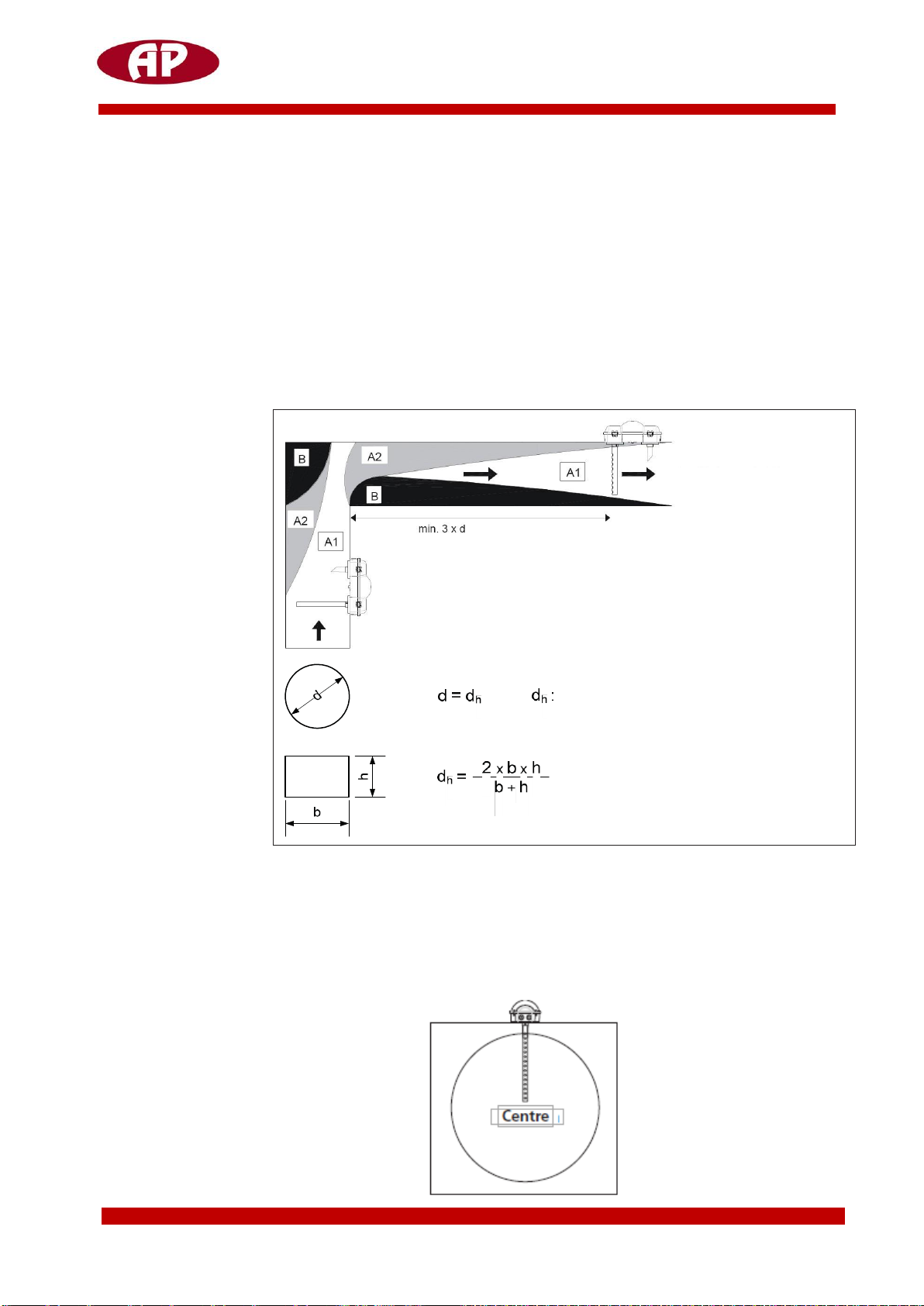

4

Project planning

...............................................................................................................................................8

5

Technical data

.....................................................................................................................................................9

6

General information

.....................................................................................................................................11

6.1

Operation of the LRS 04 Ex

.....................................................................................................................11

6.2

Transport,storageandunpacking

..........................................................................................................11

6.3

Scope of delivery

.......................................................................................................................................11

7

Rules and regulations

...................................................................................................................................12

7.2

Safety in potentially explosive atmospheres

...........................................................................................13

7.3

Intended use

...............................................................................................................................................13

7.4

General safety information and

protective measures

.......................................................................14

7.4.1

Explosion-protection regulations

..............................................................................................14

7.4.2

Classification of hazardous areas

..............................................................................................17

8

Product description

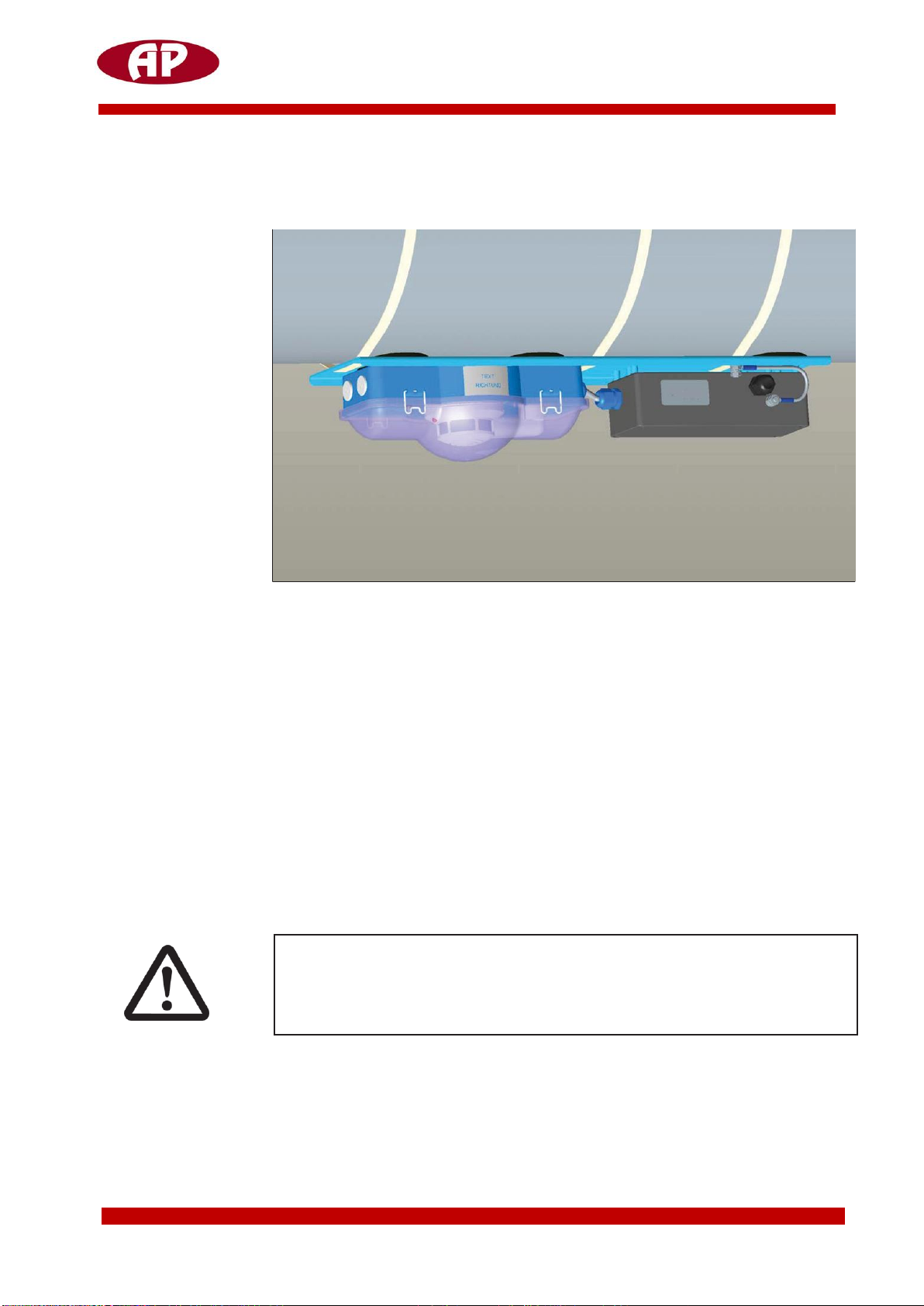

........................................................................................................................................18

8.1

Design and mode of operation

of LRS 04 Ex

.........................................................................................18

8.1.1

Terminal assignment in the connection box of the

LRS04Ex

..........................................20

8.2

Device functions and display elements of

the LRS 04 Ex

...................................................................20

8.3

Accessories for the LRS 04 Ex

...................................................................................................................21

8.3.1

Power supply and tripping unit NAG 03

.................................................................................21

8.3.2

Signal and display control element SAB 04

...........................................................................24

8.3.3

Manual actuation pushbutton 422 Ex

.....................................................................................24

8.3.4

Connection box Ex

..........................................................................................................................25