Trox RM-O-VS User manual

Smoke Detector

Type RM-O-VS

Approved by the German Institut für Bautechnik

4/6.1/EN/3

Contents · Technical Data

Contents · Technical Data 2

Description · Application 3

Installation Instructions 4

Circuit Diagram · Wiring Diagrams 5

Overview of Functions 6

Inspection and Maintenance 7

Order Details 8

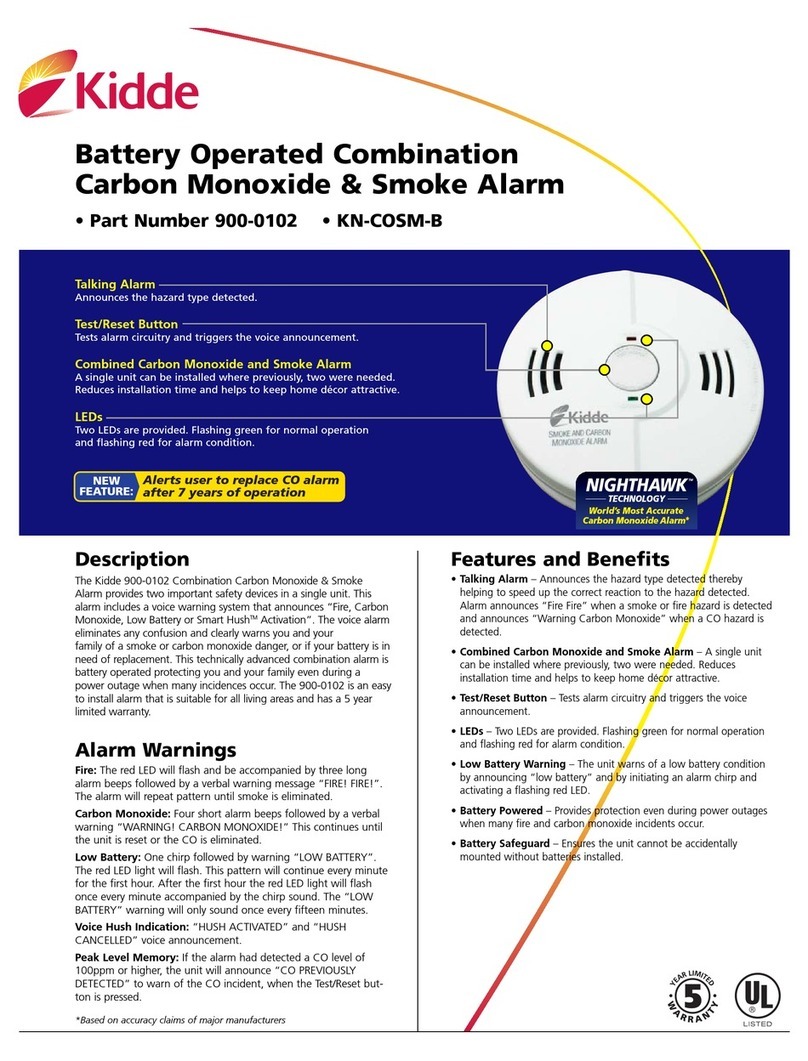

Smoke detector with power supply, monitoring electronics,

smoke alarm and air velocity monitor

Connection (plug socket) for diagnostic instrument

Push button “Test/Reset”

Green LED “System Monitoring”

Red LED “Alarm”

Yellow LED “Pollution Monitoring”

Blue LED “Air Velocity Monitoring”

Remote control terminal

Diagnostic instrument

Note:

Smoke detectors type RM-O-VS require maintenance

only once per year due to the increased safety

monitoring function.

Technical Data

– Supply voltage: 230 V, 50/60 Hz

– Power consumption: max 25 VA

– Enclosure rating: IP 42

– Permitted ambient temperature: + 10 °C to + 60 °C

– Permitted air velocity in ventilation duct:

1 m/s to 20 m/s

– Permitted relative humidity: 0 – 90% relative humidity

(condensation and water vapour can cause false alarms)

– Warning limit for air flow: 2 m/s

– Warning limit for high pollution: > 70 ± 10 units

– System monitoring: electric fault

– EMC: interference suppression to EN 60801-2 and

60801-4

– Weight: 1,5 kg

Scope of Supply

Visual smoke alarm, power supply, switched relay, signal

lights (LED), pushbutton, remote control and diagnostic

instrument connection, electronic monitor, integrated in

a plastic housing, wired ready for connection to snap

terminals, drilling template and fixing materials.

Available accessories:

– Diagnostic instrument type D-RM-O-VS to scan pollution

level, measurement range 0 to 100 units; hand held unit

with 1m long connecting lead and plug, battery supply

9 V.

– Remote control terminal type T-RM-O-VS surface

mounting or type T-RM-O-VS/1 panel mounting (size

48 x 96 x 63) with LED’s for alarm, air flow, pollution and

system monitoring; plug socket connection for diagnostic

instrument type D-RM-O-VS and pushbutton for test/reset

function.

2

Smoke Detector

Type RM-0-VS

Terminal

Type T-RM-0-VS

Terminal

Type T-RM-0-VS/1

Diagnostic

Instrument

Type D-RM-0-VS

Description · Application

3

Description

The smoke detector works on the optical light scattering

principle and is used to monitor the ventilation duct in air

conditioning systems. When used with a fire damper, it

prevents cold smoke with a temperature of 72 °C from

propagating through the AC system.

In the function mode, the smoke alarm of the smoke

detector is permanently flushed by the air flow in the duct

being monitored. If the smoke density exceeds a specific

concentration, the smoke alarm breaks the power circuit

to the control device of the fire damper; and the damper

closes. To ensure the specified function, the smoke detector

is also fitted with an air velocity sensor which monitors the

air flow in the immediate vicinity of the smoke alarm. A lack

of air flow, eg. caused by a closed damper or fan failure, is

signalled by an LED and opening relay contact.

The electrical safety circuits of the smoke detector are

constantly checked electronically and signalled on failure

by an LED and closing relay contact. At the same time, the

opening of the alarm relay contact interrupts the control

circuit and the fire damper closes. To avoid false alarms

due to pollution, the smoke alarm sampling chamber is

continuously monitored electronically. If a permitted threshold

of “> 70 ± 10 units” is exceeded, a signal is given by an LED

and closing relay contact.

The actual pollution value can be scanned directly at the

smoke detector or on the remote control terminal using the

diagnostic instrument.

Installation of a remote control terminal enables the electrical

function tests to be carried out from a central point, e.g. fire

control room.

Application

All fire dampers fitted with electric or electric/pneumatic

control devices which operate when voltage is removed may

be controlled via the smoke detector.

This is recorded in the general building authority permits for

Trox fire damper.

The smoke detectors are marked with the U symbol in

accordance with the Approval Mark regulations in Germany.

The external verification prescribed by law is carried out by

VdS e.V, Cologne.

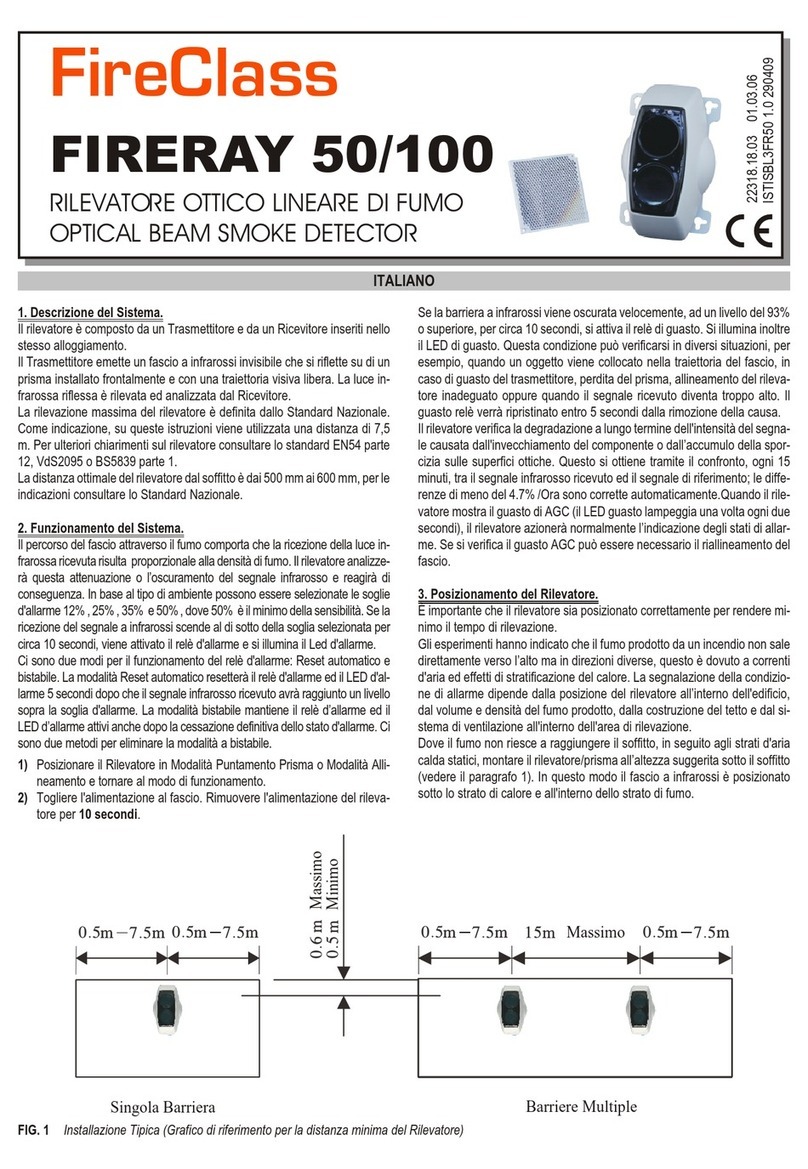

Smoke detector with

power supply, monitoring

electronics, smoke alarm

and air velocity monitor

Remote control terminal

Diagnostic instrument

Fire damper

Spring return actuator

Central control point

Test

Rückstellung /

Reset

Rauchauslöseeinrichtung

Typ RM-O-VS

>70% v<2m/sec

Elektronik

Rauch /

Smoke

Schmutz /

Pollution

Luft /

Air

Betrieb / Operation

Gebrüder TroxGmbH

D-47504 Neukirchen-Vluyn

Telefon0 28 45/2 02-0

Telefax0 28 45/20 22 65

Alarm / Störung / Failure

Anschluß

Diagnosegerät

Diagnostic link

Betrieb / Operation

Alarm / Störung / Failure

Rauch /

Smoke

Elektronik

Test/ Rück-

stellung

Reset

Anschluß

Diagnosegerät

Diagnostic link

Schmutz /

Pollution

Luft /

Air

>70% v < 2m/sec

TerminalT-RM-O-VS zur

Rauchauslöseeinrichtung

RM-O-VS

15

Typ D-RM-0-VS

1

8

9

10

11

12

Airflow

v = 1-20 m/s

Installation Instructions

Smoke detector with power supply, monitoring

electronics, smoke alarm and air velocity monitor.

1.1

Housing cover

Air duct provided by others

Drilling template

Fixing screw

Inspection opening by others

Electrical connections

Installation Instructions

– The smoke detector must be installed on a vibration-free

surface, in an area of the duct to be monitored having a

uniform air flow over the smoke alarm during normal

operation.

– Attach the drilling template to the centre of the air duct

(H/2) and drill holes.

– Remove housing cover.

– Attach housing to air duct.

– For visual inspection or to replace the smoke alarm, an

inspection opening should be provided on the upper or

lower side of the air duct.

Optional electrical connections (mains connection and

connection to control device of fire damper) should be

such that the entire smoke detector can be removed to

replace the smoke alarm.

The smoke alarm can be released from its lock by turning

anti-clockwise. When re-inserted it is locked by turning

clockwise.

– Connect control device of fire damper to the smoke

detector (terminal strip L3).

– Connect to mains.

– Connect remote control terminal (if required);

connection lines: twin core telephone cable.

– Fit housing cover.

4

145

205

80

115

185

30

88

1.1

H/2

H

Rauchauslöseeinrichtung

TypRM-O-VS

Luftrichtung

Ø 90

Air intake opening

(Distance from internal side

of the ventilation duct)

Air flow direction

Circuit Diagram · Wiring Diagrams

5

Fig 1

Fig 2

Fig 3

Fig 4

N (–)

L (+)

24 V

230 V

50/60Hz

F1

b3

L4L3L9L7

b1

L10

b4b2

B2

PE

123456789

10

456

123

123

123

123

123

L1

LLN

PE

N

L1

LLN

PE

N

L1

LLN

PE

N

L1

LLN

PE

N

123456789

10

L4

L4

L4

L3

L3

L3

B1

+–

A

AA

AA

The entire electrical installation must be in accordance with VDE

and the local EVU regulations.

Fig 1 Connection diagram for smoke detector

(fire damper closed)

Fig 2 Installation without separate power supply to DC

control device

A

on the fire damper to be controlled,

maximum load: 8 W / 24 V-

Fig 3 Installation with separate power supply for

control device

A

on the fire damper to be controlled,

maximum switched power 250 V / 10 A

or 24 V- / 200 W

Fig 4 Special installation (voltage on to operate principle)

without separate power supply to AC control device

A

on the fire damper to be controlled,

maximum switched power 250 V / 10 A

L

1

Mains connection 230V 50/60 Hz

L

3

Control device connection (volt-free)

Switched power 250 V / 10 A or 24 V- / 200 W

L

4

Connection of external control max 8 W / 24 V-

Connection for 24 V- external supply:

Residual wave max 2 %;

Consumption min 520 mA;

Without 8 W consumption 190 mA

L

9

– L9/1-2 air velocity monitoring (volt-free)*,

– L9/3-4 pollution monitoring (volt-free)*,

– L9/5-6 system monitoring (volt-free)*

* Switched power 110 V/4 A, 24 V-/100 W

L

7

/L

10

Connection for remote control type T-RM-O-VS or

T-RM-O-VS/1; for remote control, remove link L7/1-2

b

1

b

2

Pushbutton test/reset

b

3

b

4

Connection (plug socket) for diagnostic instrument

type D-RM-O-VS

F

1

Fuse 500 mAT

B

1

Link (by others) for connecting

230 V, 50/60 Hz detector

B

2

Link (by others) for connecting

24 V- control device max 8 Watts

A

Control device for fire damper

(AC or DC)

For parallel control

Smoke detector type

type RM-0-VS

Remote control

Type: T-RM-0-VS

Type: T-RM-0-VS/1

Velocity

monitor

Smoke alarm

Overview of Functions

6

Fire damper

Open Closed

Operating Mode / Event

Mains connected

– Function status –

Mains not connected

Mains connected,

faulty electronics or

link L7/1-2 or

remote control or

smoke alarm not fitted

Pollution Level 1)

70 units

100 units

Test / Reset

– Inspection –

Smoke / Pollution 1)

100 units 3)

– Alarm status –

LED

Contact

LED

Contact

LED

Contact

LED

Contact

LED

Contact

LED

Contact

Signal

Red LED

Alarm

Blue LED

Velocity

Monitoring

Green LED

System

Monitoring

Terminal Strip

– L9–

6 5

Terminal Strip

– L9–

4 3

Terminal Strip

– L9–

2 1

Terminal Strip

– L3–

2

3

1

Yellow LED

Pollution

Monitoring

With air flow: LED on

Without air flow: LED off

relay contact:

relay contact:

2)

2)

1) Pollution corresponding to diagnostic instrument display:

Up to 70 units – Normal range –

70 units – Warning level –

100 units – Alarm status –

2) May indicate a transitional state, e.g. caused by a cloud

of dust

3) An alarm triggered by smoke (event or maintenance) can

only be cancelled by pressing the button after the smoke

alarm head has cleared of smoke.

: LED on : LED flashing : LED off

Inspection and Maintenance

7

Function Test

Smoke detectors must be inspected every 3 months after

commissioning of the air conditioning system and

maintenance carried out at yearly intervals. Inspection

and maintenance can be carried out at the same time.

Inspection

Pressing the “Test/Reset” button on the smoke detector

or on the remote control terminal interrupts the circuit to

the control device on the fire damper which then closes.

On releasing the button, fire dampers with actuators

automatically return to the open position. Fire dampers

with solenoid or magnet release must be opened locally

by hand.

The fouling of the smoke alarm can be scanned directly on

the smoke detector using the diagnostic instrument and/or

via the remote control terminal.

For signal indication, see overview of functions, page 6.

Maintenance

Check the following:

– Application and installation position

(during commissioning and after system changes)

– Correct electrical connections and no loose wires in

terminals

– Electrical interaction of signal emitter, display and control

devices on fire damper

– Response of smoke alarm to smoke aerosol, e.g. cigarette

smoke or smoke from smoke cartridge. When the

permitted concentration limit is exceeded, the smoke

alarm interrupts the circuit to the control device on the

fire damper to be controlled and the damper closes

– Check response of air velocity monitor, e.g. switch off fan

For signal indication see overview of function, page 6.

Eliminating Faults

If inspection or maintenance has revealed any faults, these

must be repaired immediately. Faulty components must be

replaced only by original Trox spare parts.

Only the manufacturer may make repairs to the smoke

detector.

If a function test reveals that the smoke detector is working

correctly but the fire damper to be controlled is not closing,

the control device on the damper and the damper itself

must be checked for operation.

Smoke detector with power supply, monitoring electronics,

smoke alarm and air velocity monitor

Connection (plug socket) for diagnostic instrument

Pushbutton “Test/Reset”

Green LED “System Monitoring”

Red LED “Alarm”

Yellow LED “Pollution Monitoring”

Blue LED “Air Velocity Monitoring”

Air duct supplied by others

Test tube for checking

response/function

(by others)

13

1

2 3 45 6 7

Approx. 80-90

20

Approx. 90-100

Design changes reserved · All rights reserved © Gebrüder Trox GmbH (10/2000)

Order Code

Order Details

8

Description

Smoke detector (smoke detection using optical light scattering

principle) with general building supervision approval from the

Institut für Bautechnik Berlin, for fire dampers with electric

or electric/ pneumatic control device (voltage off to operate),

suitable for protection against smoke transmission in air

conditioning systems, even with cold smoke t 72 °C;

suitable for air velocities of 1 m/s to 20 m/s.

With additional functions for monitoring the air flow in the

measurement area of the smoke alarm, the pollution level

on the smoke alarm sampling chamber and the system

electronics (maintenance once/year).

Scope of supply: see page 2.

Order Example

Make: TROX

Type: RM-O-VS

Quantity: 5

RM-O-VS

Order Code

Description:

Diagnostic instrument for smoke detector RM-O-VS to scan

pollution level.

Measurement range 0 – 100 units; hand unit with 1m long

connection lead and plug; battery supply 9 V.

Order example

Make: TROX

Type: D-RM-O-VS

Quantity: 1

D-RM-O-VS

Order Code

Description:

Remote control terminal for smoke detector RM-O-VS for

surface mounting or panel mounting (size 48 x 96 x 63) with

signal LEDs for alarm, air flow, pollution and system

monitoring; socket connection for diagnostic instrument

D-RM-O-VS and pushbutton for test/reset function.

Order Example

Make: TROX

Type: T-RM-O-VS or T-RM-O-VS/1

Quantity: 5

T-RM-O-VS or T-RM-O-VS/1

Table of contents

Other Trox Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

Landmann

Landmann Great Outdoors Smoky Mountain 3425GLA Assembly and owner's manual

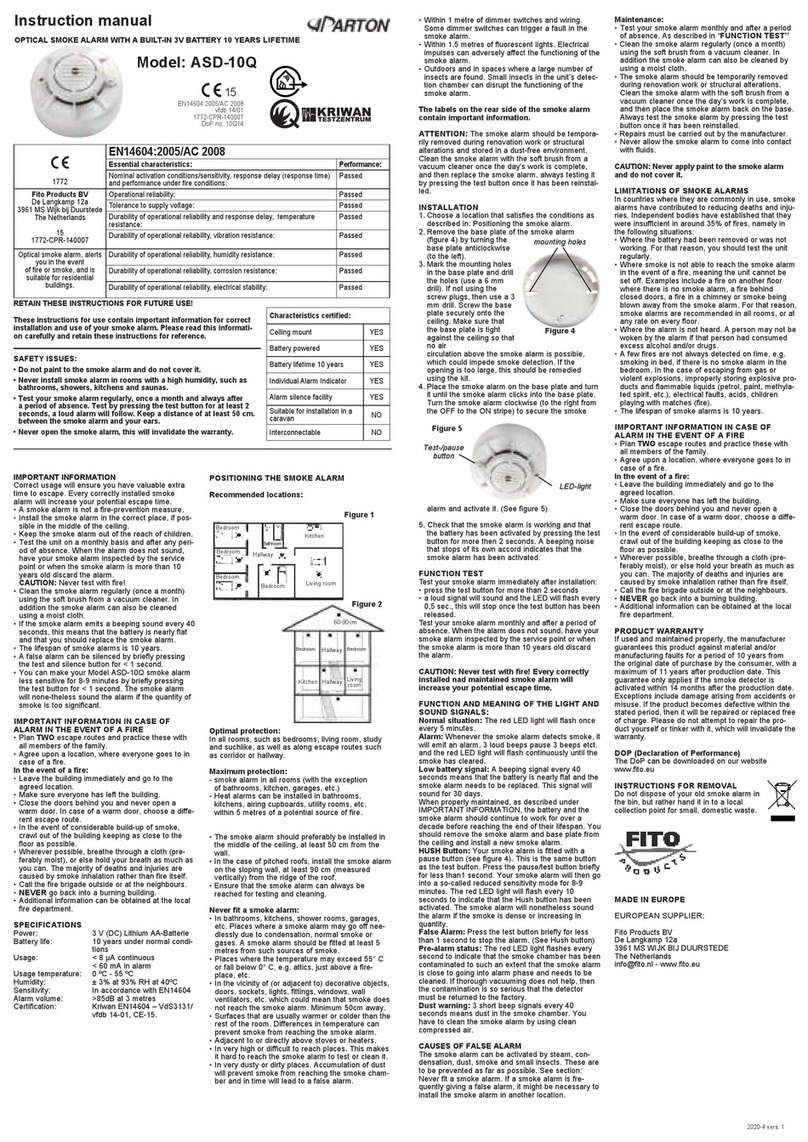

Aparton

Aparton ASD-10Q instruction manual

First Alert

First Alert PC910 user manual

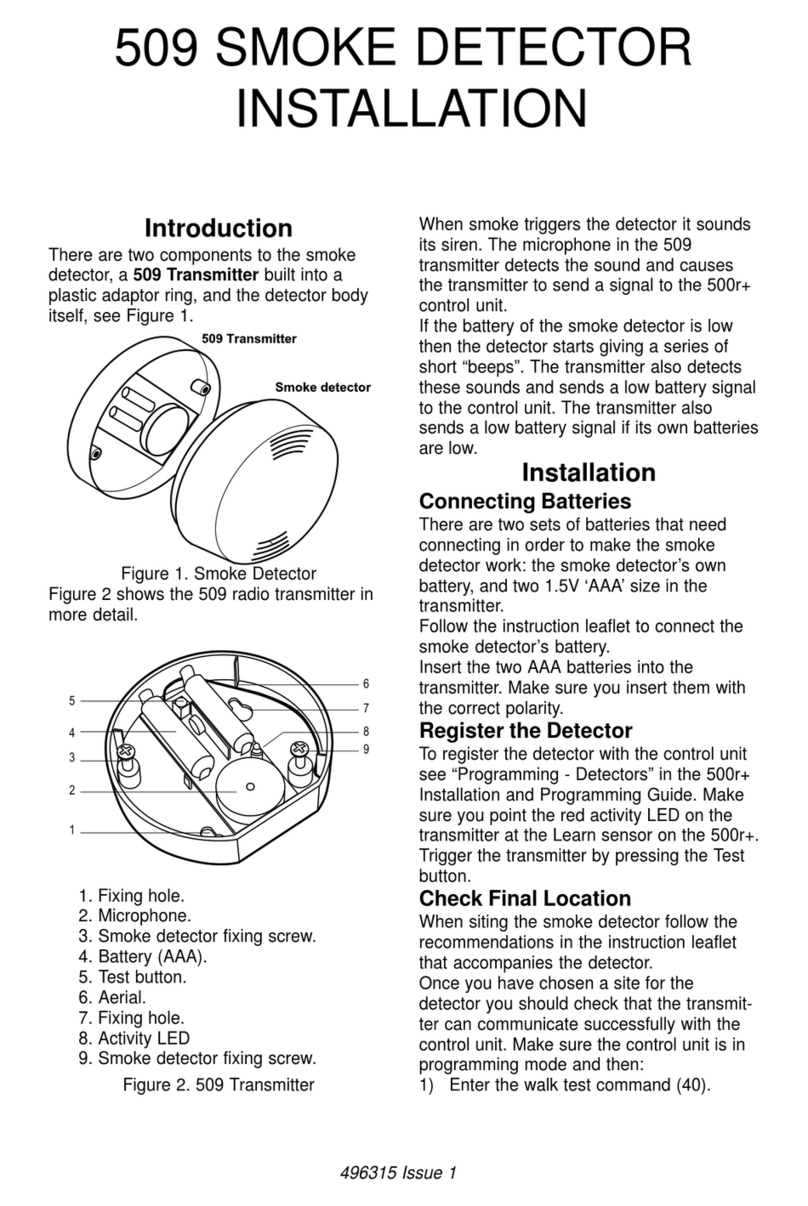

Cooper

Cooper Scantronic 509 installation manual

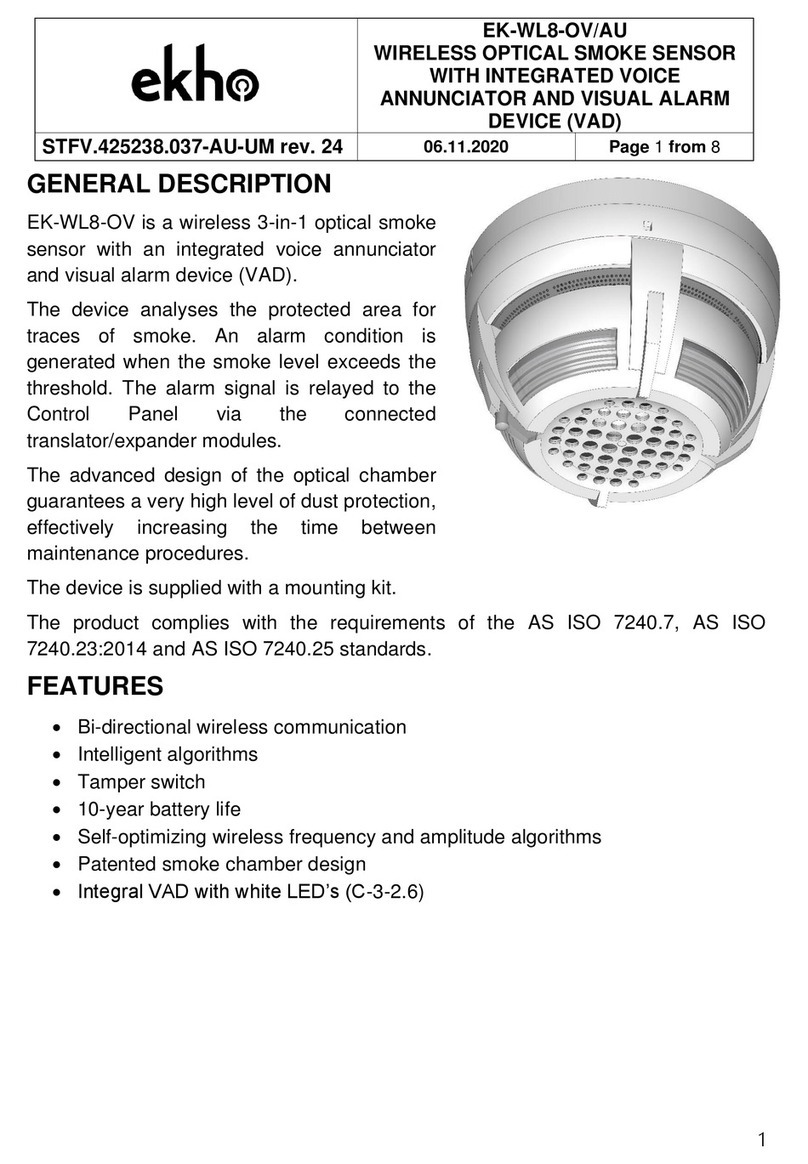

EKHO

EKHO EK-WL8-OV General description

Universal Security Instruments

Universal Security Instruments MDS300 instructions