Page 4

A

M

E

R

I

C

A

N

P

I

L

E

D

R

I

V

I

N

G

E

Q

U

I

P

M

E

N

T

A

M

E

R

I

C

A

N

P

I

L

E

D

R

I

V

I

N

G

E

Q

U

I

P

M

E

N

T

800-248-8498800-248-8498

WWW.AMERICANPILEDRIVING.COMWWW.AMERICANPILEDRIVING.COM

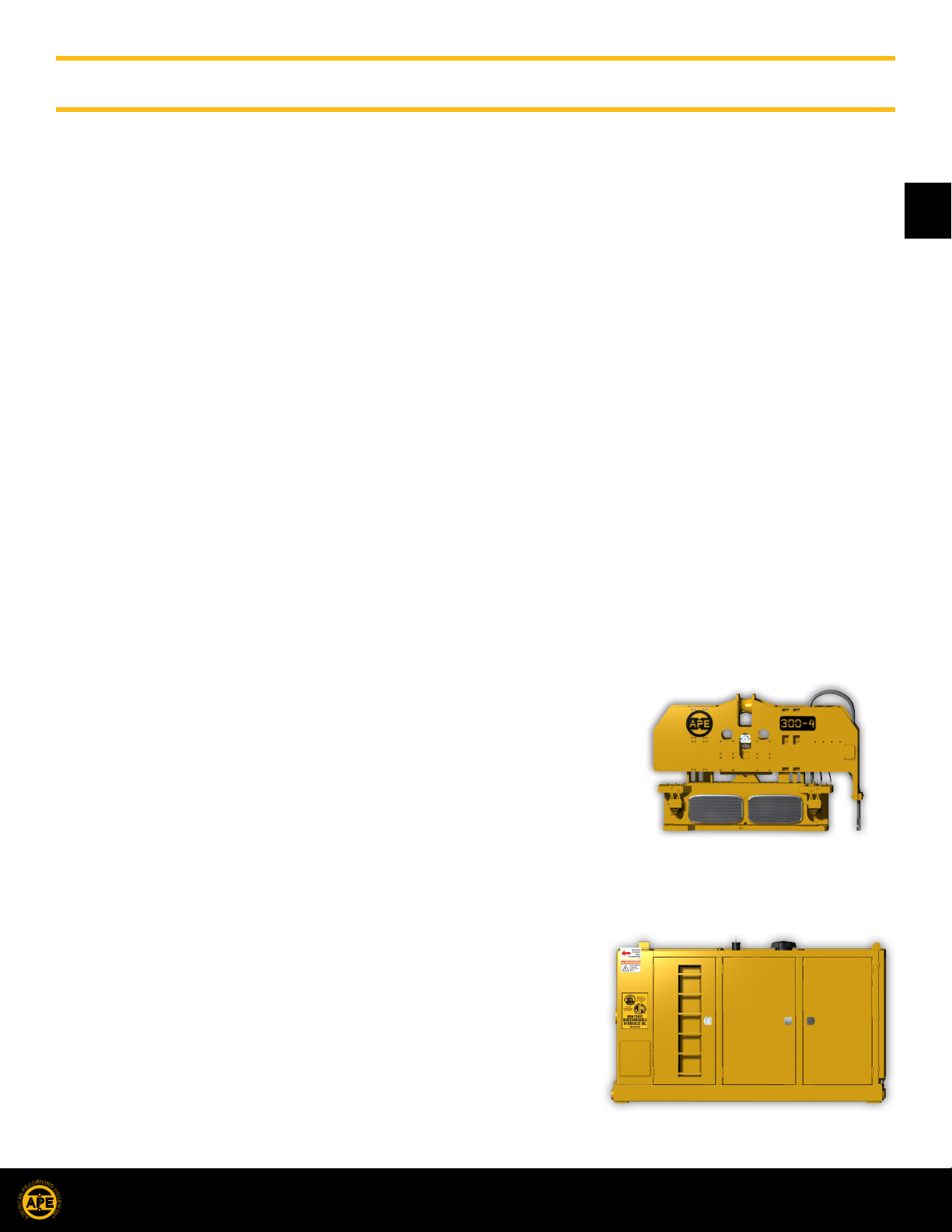

MODEL 300-4 VIBRO

Copyright © 2020 American Piledriving Equipment Inc. All Rights Reserved

Remove all tools, parts and electrical cords

Do NOT

NOT smoke or use

If abnormal equipment operation is observed,

Do NOT

Do NOT operate this equipment with hydraulic

Do NOT

Do NOT

Do NOT pull on and/or attempt to move

Do NOT attempt to locate hydraulic leaks with

Do NOT attempt to repair leaks while the

Do NOT

equipment, insure that the vehicle or vessel is

necessary to prevent parts on this equipment,

Do NOT

Keep excavator, piles, vibrator, wire rope, and

electrical power lines, transformers, and other

electrical equipment, or at such distance as

radius tables to be sure capacity is adequate for

Check vibrator suppressor for broken or

Do NOT run the vibrator without clamp jaws