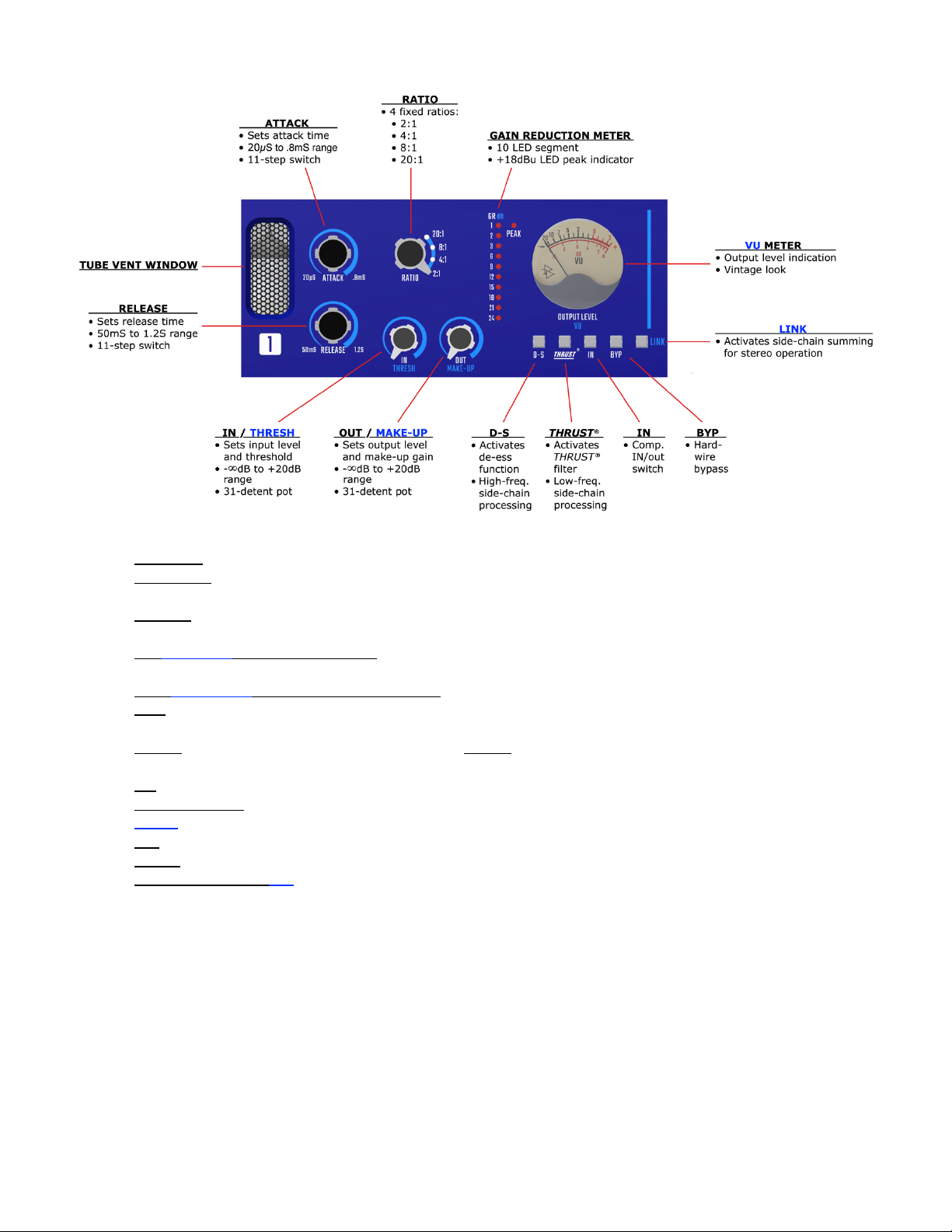

T25 Tube Compressor API Select

5.0 Side-Chain and Routing Controls

The T25 Tube Compressor is equipped with a flexible set of side-chain processes and routing controls.

Frequency-dependent side-chain processing includes a de-esser and the patented

THRUST

®filter that

helps you get more punch from audio with heavy low-frequency content. These features provide

increased control of the tonal characteristics and envelope shaping the compression applies to the

audio.

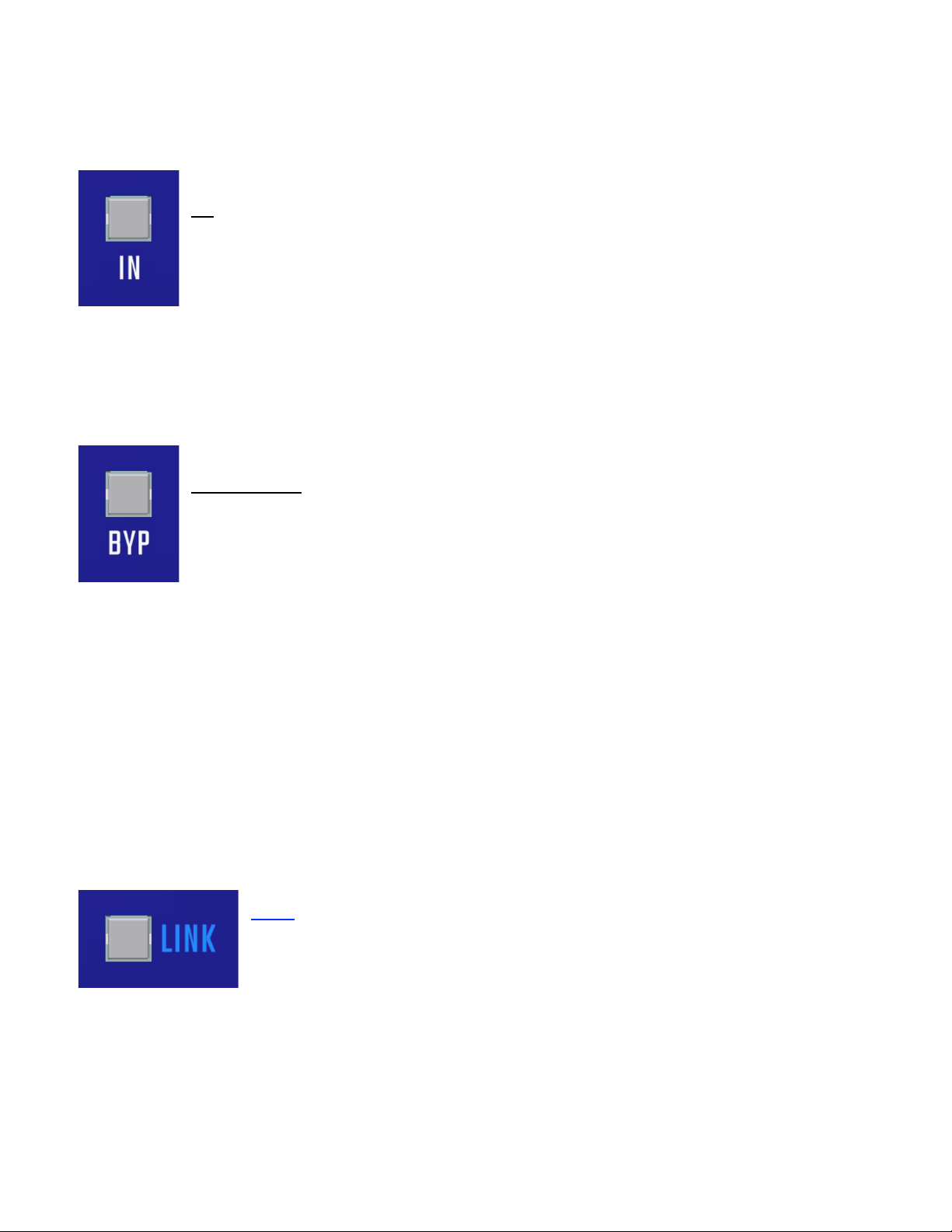

Routing options provide a compressor IN/out switch, hard-wire bypass, and linking for stereo

operation.

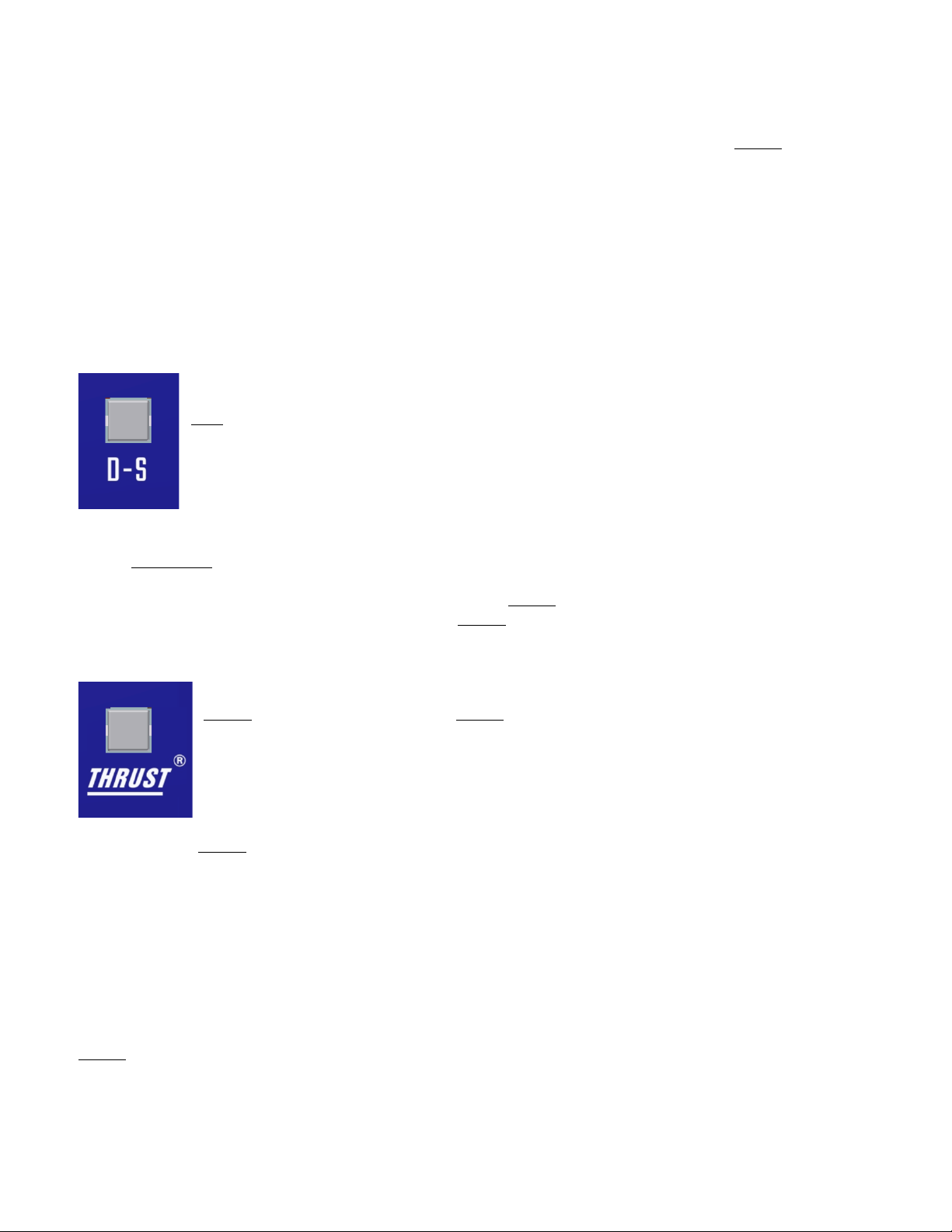

5.1 De-esser (D-S)

The D-S function provides a de-esser capability to the T25 for working with overly sibilant vocals.

D-S: Engage to activate the de-esser function

• Accentuates compression of high-frequency content

• Inserts a filter with 6kHz center before the RMS detector

• Illuminates when engaged

5.2

THRUST

®

The T25 Tube Compressor is equipped API’s patented

THRUST

®filter circuit that can be switched in or

out of the side-chain as needed. This places the

THRUST

®filter before the RMS detector that decreases

the compressor’s reaction to low frequency content. The result is a noticeable increase of punch and

low frequencies, but a uniformly compressed signal. It’s the “little more punch” switch!

THRUST

®:Engage to activate the

THRUST

®filter function

• Controls heavy low-frequency content in the detection path

• Inserts a 10dB/decade filter before the RMS detector

• Illuminates when engaged

The patented

THRUST

®circuit has been used for many years in the famed API 2500+ Stereo

Compressor, ATI Paragon and Paragon II consoles, as well as the Pro6 Input Strip. This circuit places

a filter in front of the RMS detector with a slope of 10dB per decade (-3dB/8va), which is the inverse

of the pink noise energy curve. In acoustics, the pink noise curve is used to equalize energy vs.

frequency over the audio spectrum, as sound requires more low frequency energy than high frequency

energy to sound correct to your ear. In Hi-fi equipment, a “LOUDNESS” contour is used to equalize

the music at lower levels so it sounds correct. Even with this curve, there is still a substantial amount

of low frequency information compared to high frequency information in the audio signal path. When

that signal is fed into the RMS detector, the detector will process the signal into a DC control voltage

based upon those louder low frequencies, resulting in a control voltage that favors the low frequencies

of the signal, causing pumping and a loss of punch. Sometimes, this is not desirable. By engaging the

THRUST

®switch, this inverse filter is placed in front of the RMS detector, evening out the energy by

lowering the energy in the low frequencies and increasing the energy in the high frequencies, so each

octave has the same energy instead of each octave having half the energy as the one lower. This

creates a unique compression effect that still reduces the overall gain, but the sound is much more

punchy and the signal actually sounds less compressed.