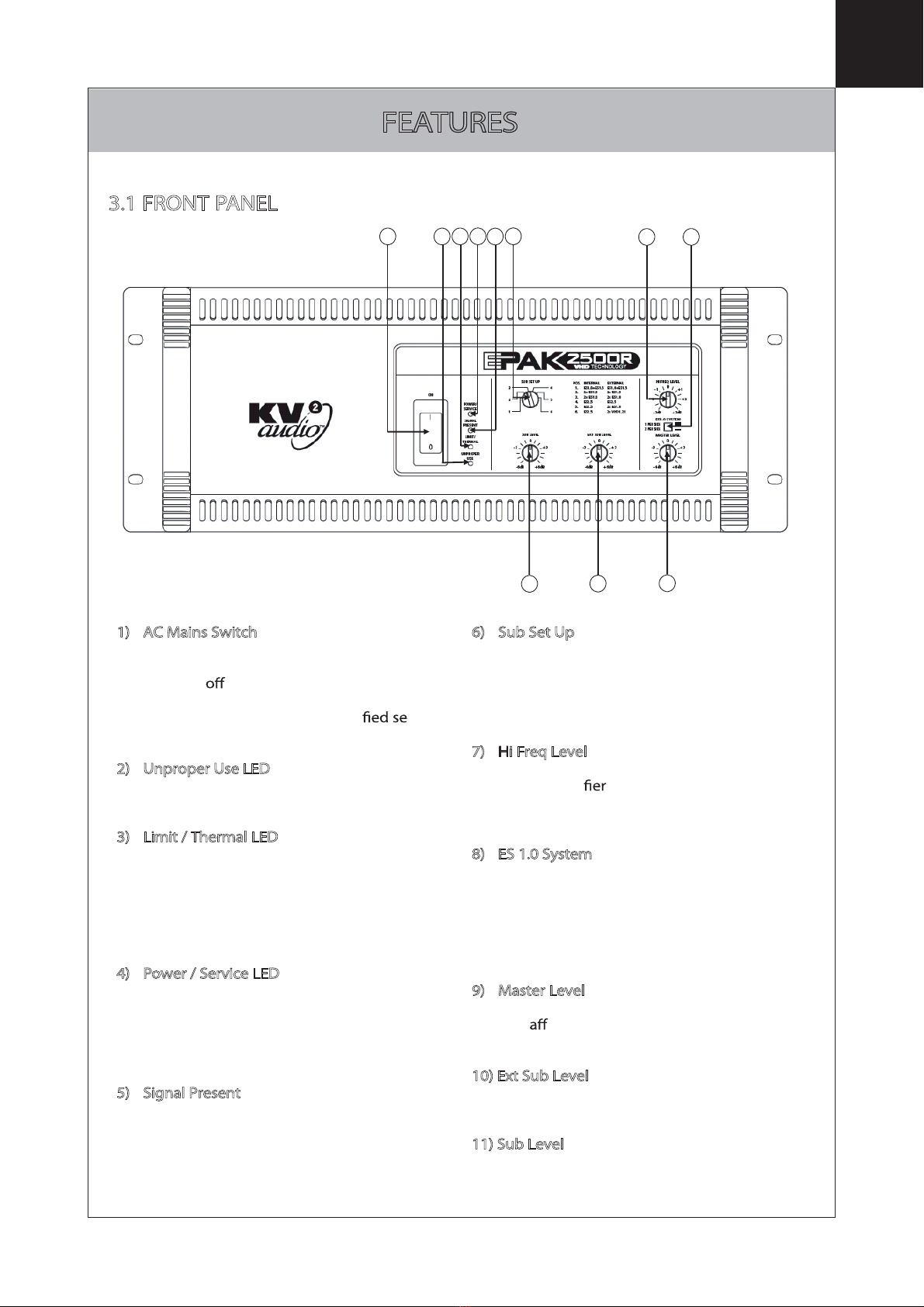

FEATURES

1) Main Input / Through Signal Out

This is the main system input connector with

associated ‘Through Signal Output’ connector

for sending unprocessed signal to other devices,

such as more EPAK 2500R’s to power more

ES 1.0’s in a system.

2)Input Z

This switch selects one of two input impedance

settings for the EPAK 2500R. The switch should

be set to the 50 Ωsetting when the EPAK 2500R

is driven from a VHD LD4 line driver. Where an

LD4 is not being used and the EPAK 2500R is

being driven from a standard mixing console

output, then the 10k Ωsetting should be used.

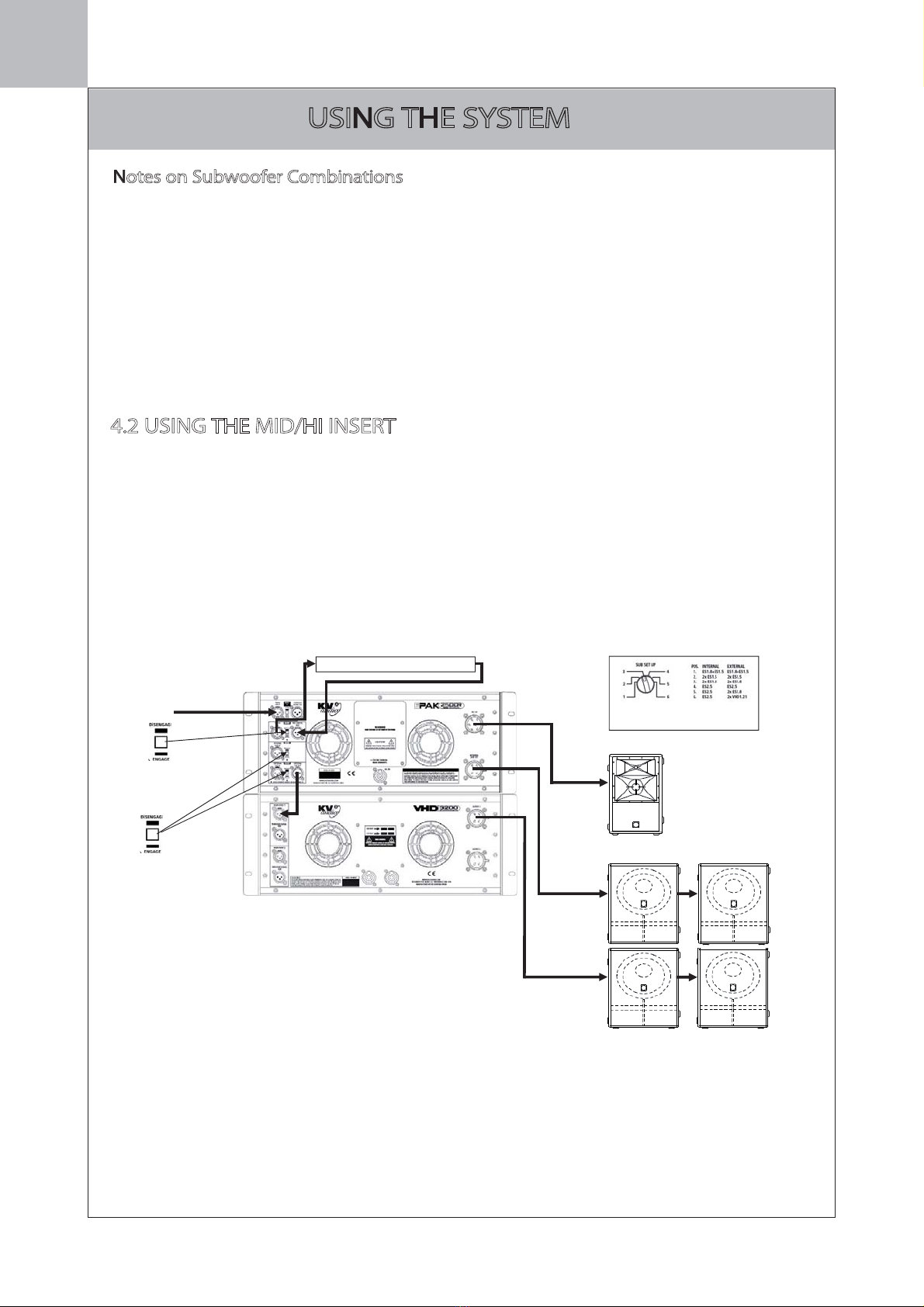

3)Mid/High In / Pre Control Out

This is an insert point for the Mid/High section

of the EPAK 2500R, the signal sent to the ES 1.0

cabinet. It enables you to ‘insert’ an external

device (a delay line for example) into the signal

that is being sent to the ES 1.0. With the

associated switch in the ‘Engage’ setting the Pre

Control Out connector would send the signal to

the external device, and its output would be

returned into the Mid/High In connector.

4)Internal Sub In

This ‘insert’ point allows you to drive the

internal subwoofer ampli rom an external

source. The signal for the internal subwoofer

r is usually derived from the Main Input

on the EPAK 2500R but with this Sub In and

associated switch the option is available to

derive the signal input for the internal

subwoofer section from a di rent source. For

further information see ‘Using the System’.

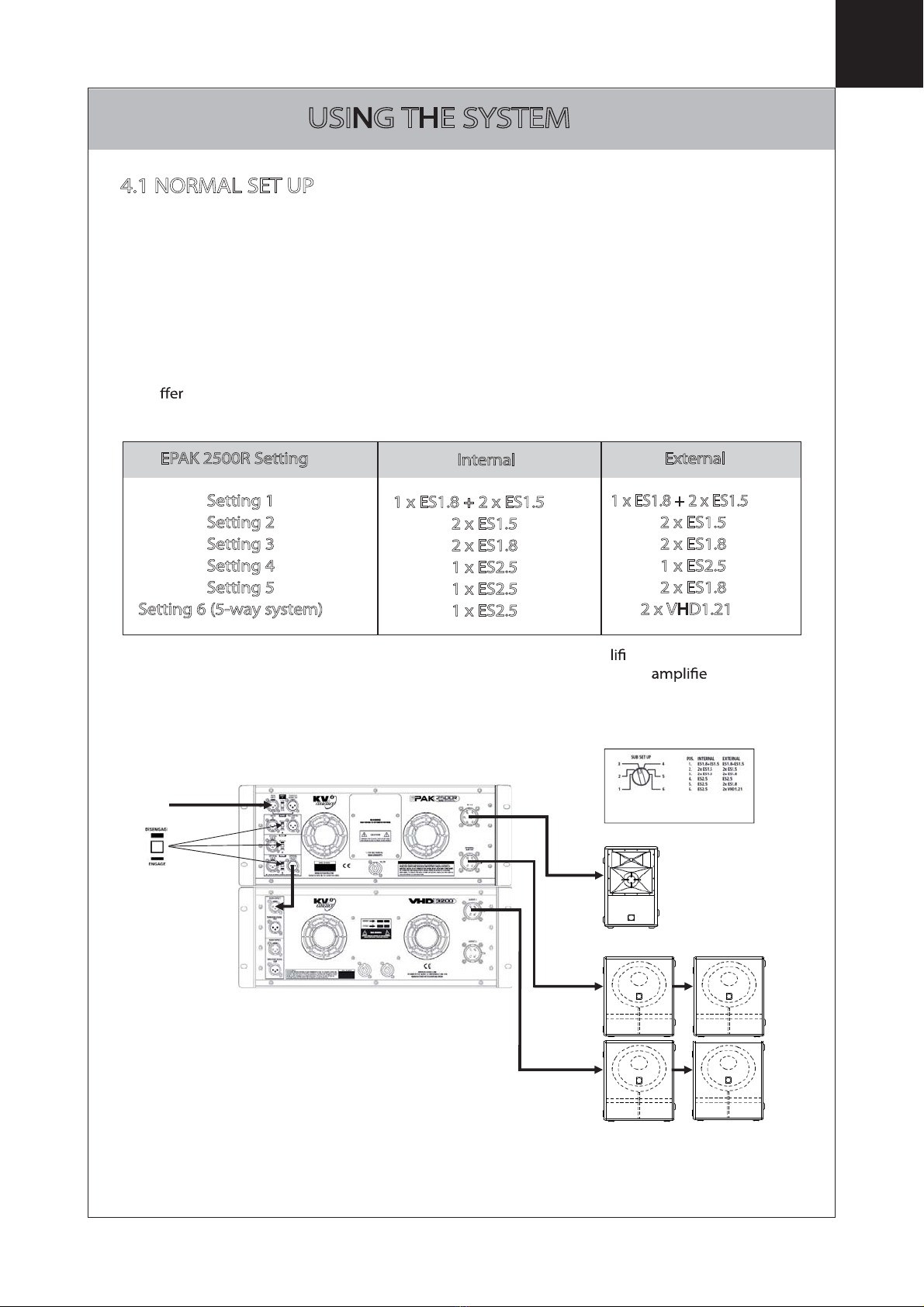

5)External Sub In, External Sub Out

Apart from providing signal processing and

power for driving the ES 1.0

enclosure and ES subwoofers the EPAK 2500R

also provides processed outputs for feeding

VHD 3200 subwoofer to drive various

combinations of ES and VHD subwoofers. The

signal for this is usually derived from the Main

Input on the EPAK 2500R but with these Sub In

and Sub Out connectors and associated switch

the option is available to derive the signal input

for the external subwoofer section from a

derent source. For further information see

‘Using the System’.

6) PowerCon Power Connector

Accepts a standard PowerCon terminated AC cable

7) Fans

The cooling fans operate continuously while the

EPAK 2500R is on. An internal temperature

sensor increases the speed of the fans during

high temperature conditions. Air enters through

the front grille and exits through the rear. Be

sure to allow adequ ow to the front of

the rack in which the EPAK 2500R is mounted.

8)ES 1.0 EP6 Connector

Accepts a standard EP6 terminated loudspeaker

cable for connecting up to a single ES 1.0

cabinet. We recommend using 2.5mm/core

cables.

9)Internal Sub EP4 Connector

Accepts a standard EP4 terminated loudspeaker

cable for connecting up to various ES series

subwoofers. We recommend using 2.5mm/core

cables.

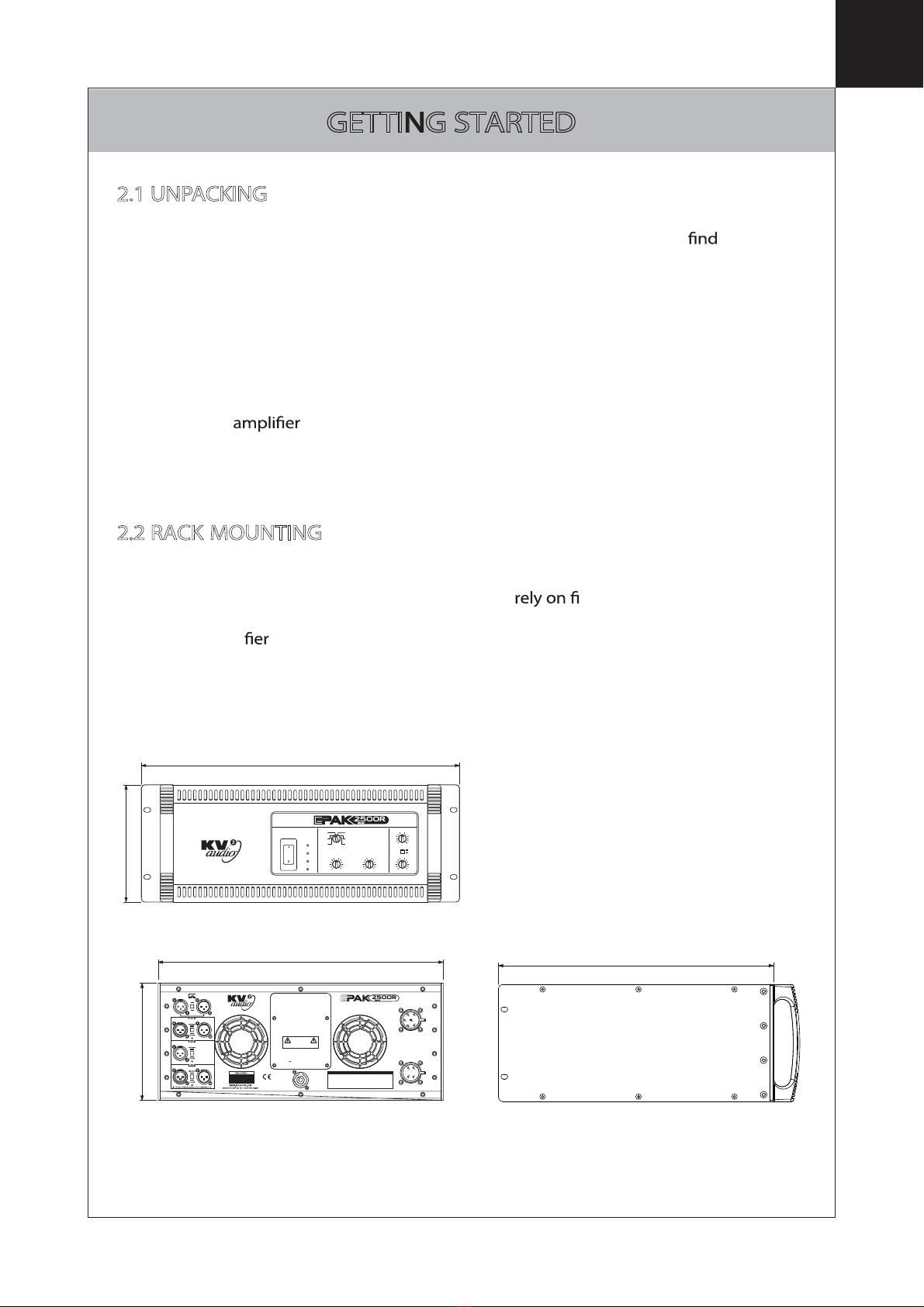

1 3 4 6 7 8

2 5 9

3

3.2 REAR PANEL