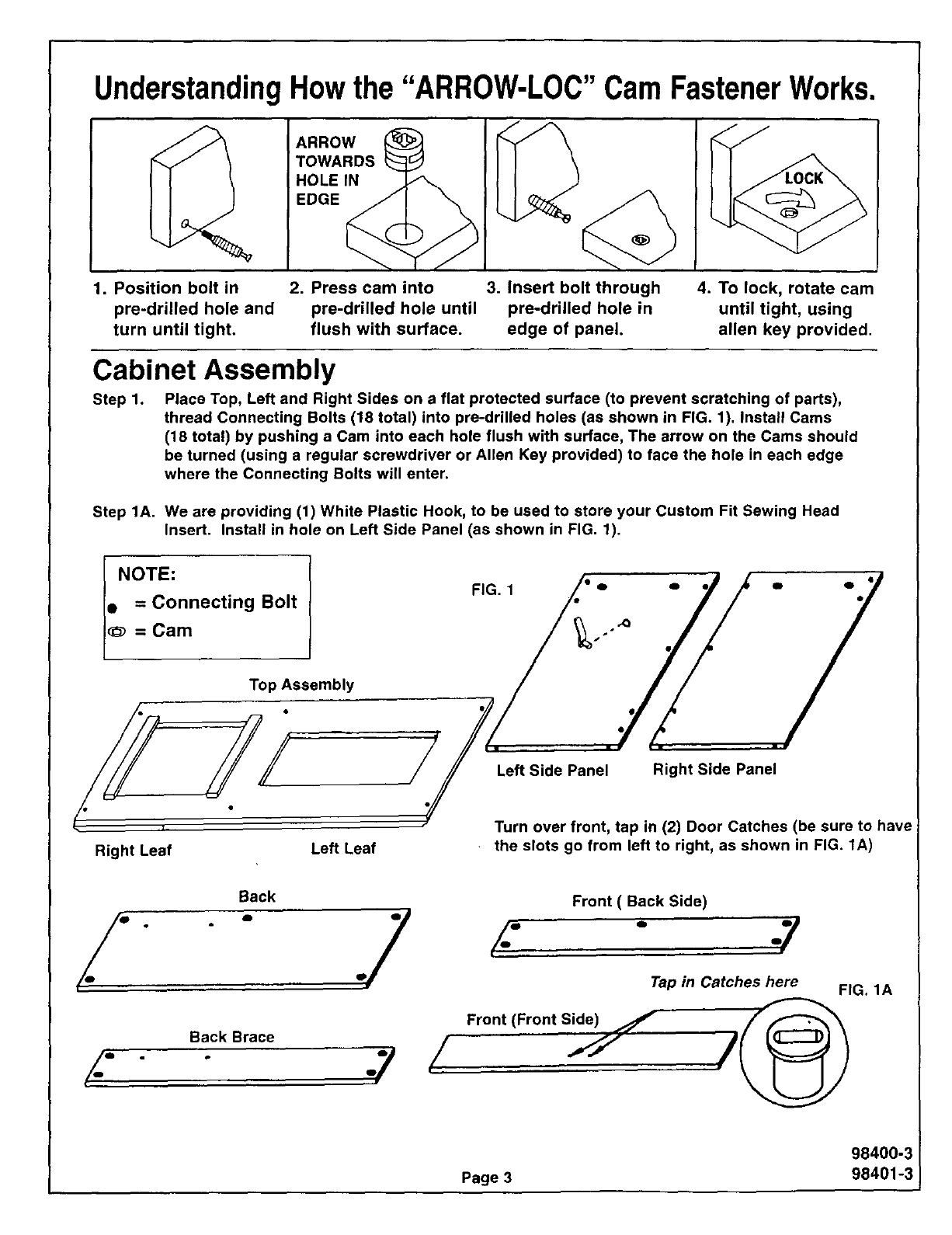

UnderstandingHowthe "ARROW-LOC" Cam FastenerWorks.

ARROW

TOWARDS

HOLEIN

EDGE

1. Position bolt in 2. Press cam into 3. Insert bolt through

pre-drilled hole and pre-drilled hole until pre-drilled hole in

turn until tight, flush with surface, edge of panel.

4. To lock, rotate cam

until tight, using

allen key provided.

Cabinet Assembly

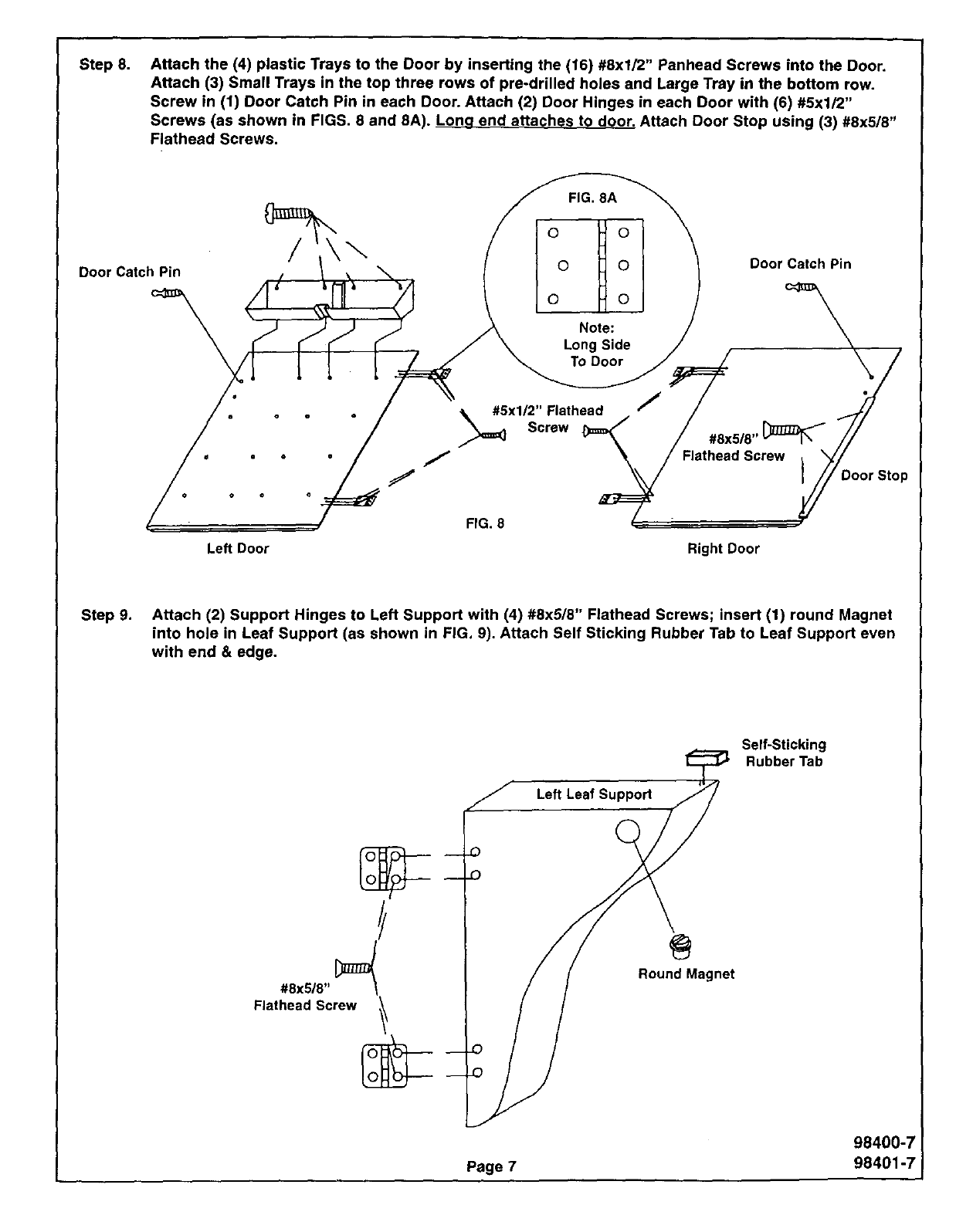

Step 1. Place Top, Left and Right Sides on a flat protected surface (to prevent scratching of parts),

thread Connecting Bolts (18 total) into pre-drilled holes (as shown in FIG. 1). Install Cams

(18 total) by pushing a Cam into each hole flush with surface, The arrow on the Cams should

be turned (using a regular screwdriver or Allen Key provided) to face the hole in each edge

where the Connecting Bolts will enter.

Step 1A. We are providing (1) White Plastic Hook, to be used to store your Custom Fit Sewing Head

Insert. Install in hole on Left Side Panel (as shown in FIG. 1).

INOTE:

• = Connecting Bolt

= Cam

FIG. 1

Top Assembly

/iJJ

Right Leaf Left Leaf

Back

./ " .7

Back Brace

Left Side Panel Right Side Panel

Turn over front, tap in (2) Door Catches (be sure to have

the slots go from left to right, as shown in FIG. 1A)

/- #

Front ( Back Side)

/. ..y

Tap in Catches here FIG. 1A

Front (Front Side)

/1I /

98400-3

Page 3 98401-3