BEFORE INSTALLATION CAREFULLY READ INSTRUCTIONS

This product should be used with cold water supply only!

1) Check that all parts are in the package.

2) Before installation, please check incoming water pressure, tank pressure and

inlet water temperature. In certain installations the use of a PRV valve and surge

vessel may be required.

3) Make sure feed water quality complies with the requirements from section 2. If

feed water quality does not meet the requirements, consult with a water treatment

specialist.

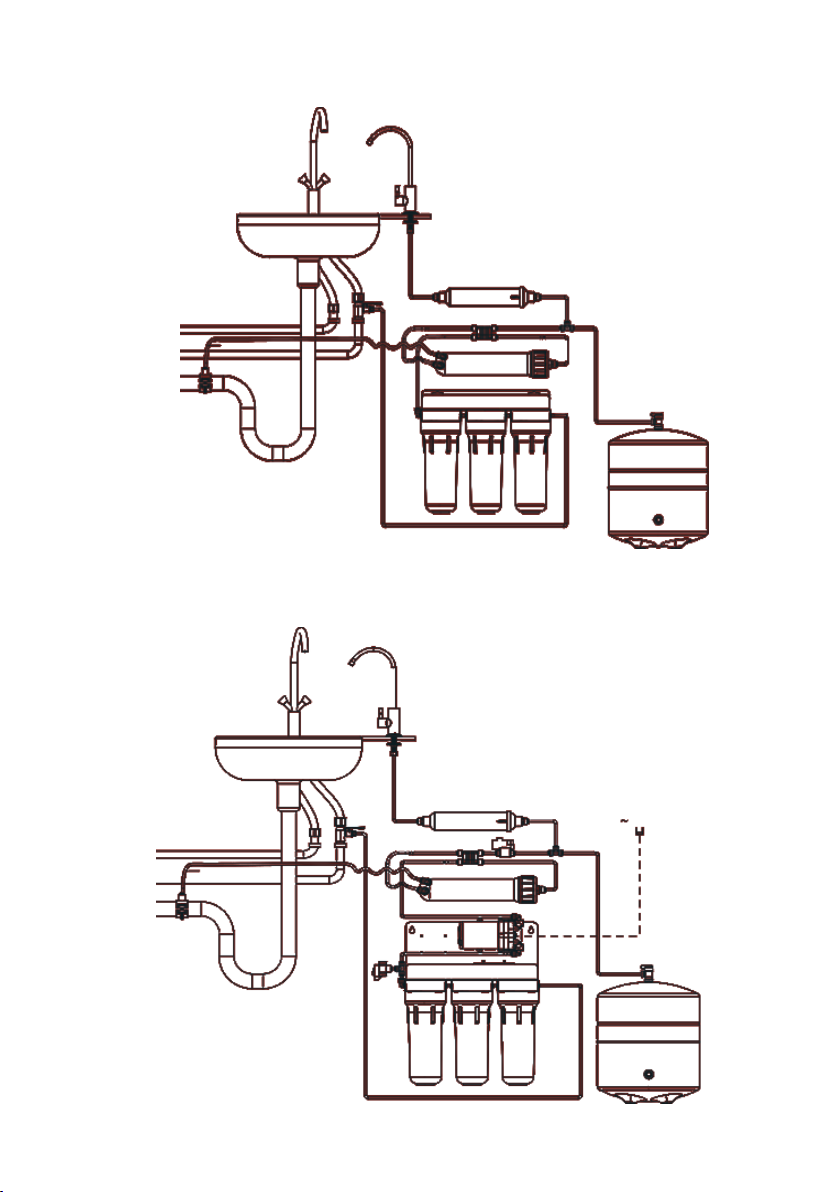

4) Before installing the system, make sure there is enough space for both the lter

rack and the pressure tank under the sink. In case there is not enough available

space, pres- sure tank can be placed in separately. Yellow tube’s length is sufcient

to connect it to the rest of the system.

5) Electrical safety notice: This appliance should be connected into a circuit with

an RCB installed. Please note voltage requirements. The unit is to be supplied with

single-phase 230 VAC, 50 Hz electrical power.The system is supplied with power

cord and can be connected to a properly installed IEC 60884-1 compliant socket.

6) Once installation has been completed and operational ensure that all ttings,

pipework, and unit has been checked for any drips and leakage.

Always ensure unit is tted in a safe and correct manner as outlined by this manual

NOTE:

This system has been tested by the manufacturer for leaks, so within the

system the presence of residual water is allowed. This system should be in

-

stalled away from direct sunlight and heating appliances.

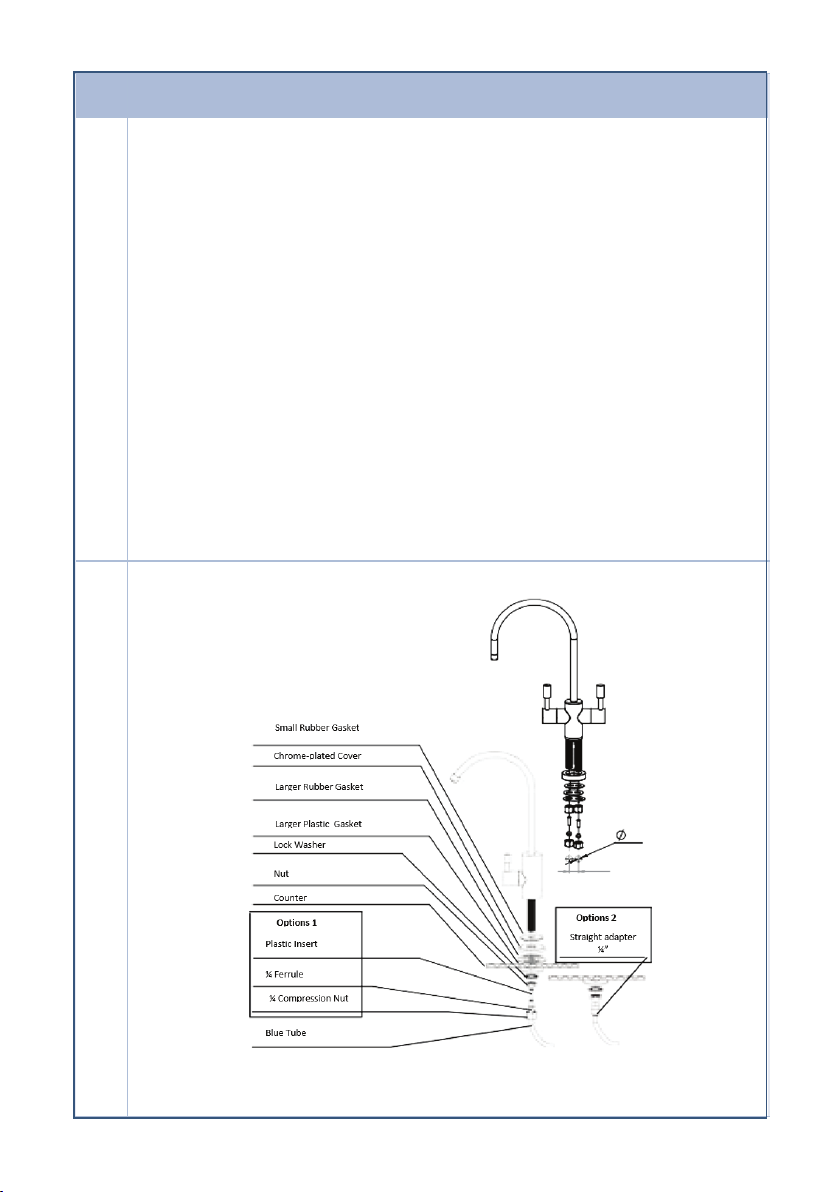

5. Installation Instructions

8