Applied

Electronics

Proudly Made in USA

?

Applied

Truss and Electronics

2

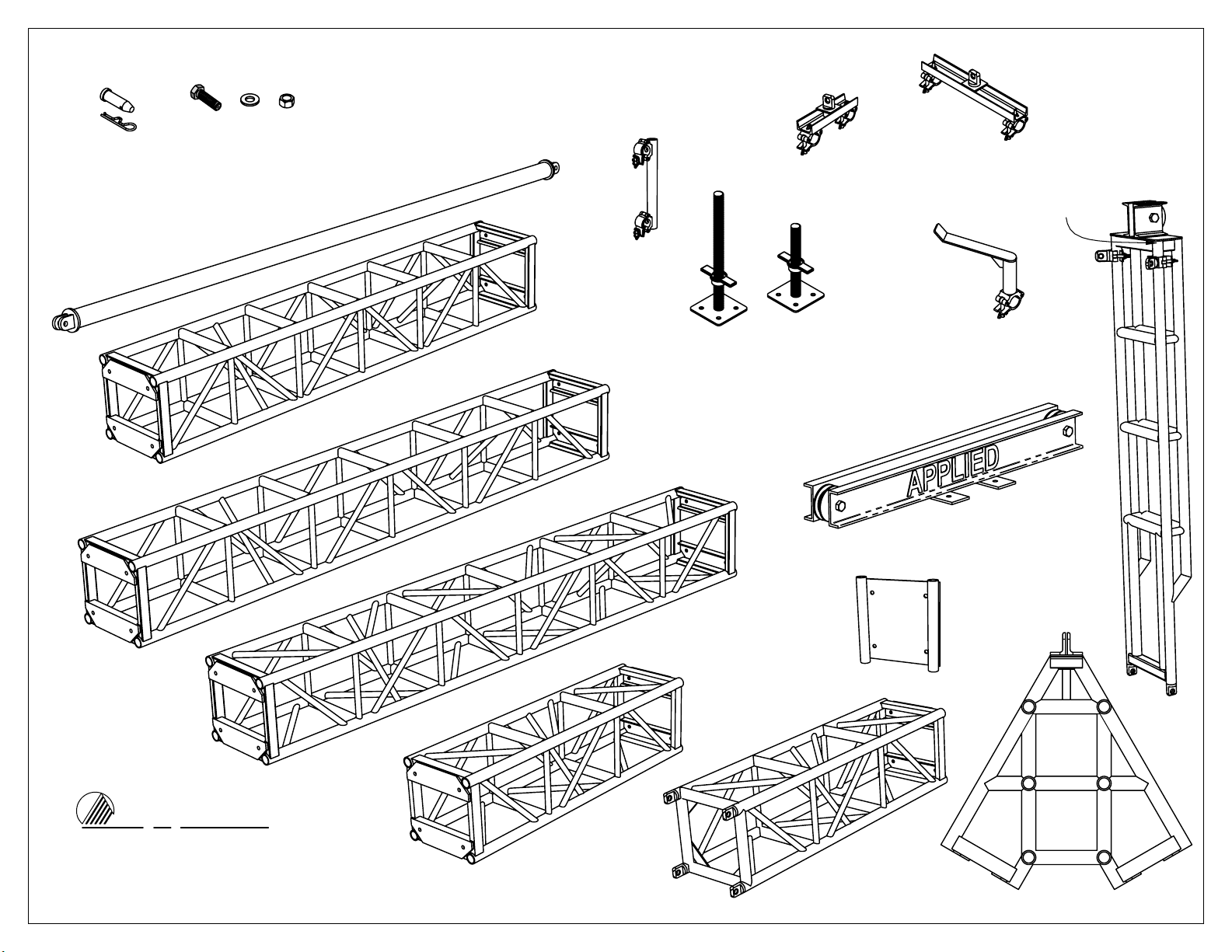

BILL OF GOODS

QTY: (2) 16” LA1635 Towers

(2) V-BASES

(2) HINGE SECTIONS

(6) 10’ 16IN TOWER TRUSS (TOWERS)

(2) HEAD BLOCKS

(4) 10’ 16IN BOX TRUSS (LEGS)

(4) 8' 16IN BOX TRUSS (LEGS)

(4) LEG PLATES

(4) LEG BRACKETS

(4) TOWER BRACKETS

(4) MOTOR SUPPORTS

(2) LIFTING LADDERS

(4) TOWER BRACES

(96) 5/8-11 BOLT SETS

> WITH (192)WASHERS AND (96) NUTS

(24) 3/4 X 2-1/2” CLEVIS PINS WITH R-CLIPS

(4) LEVELING JACK TUBES

(20) LEVELING JACKS

(2) SETS OF BUILD INSTRUCTIONS

Shipped on 2 pallets

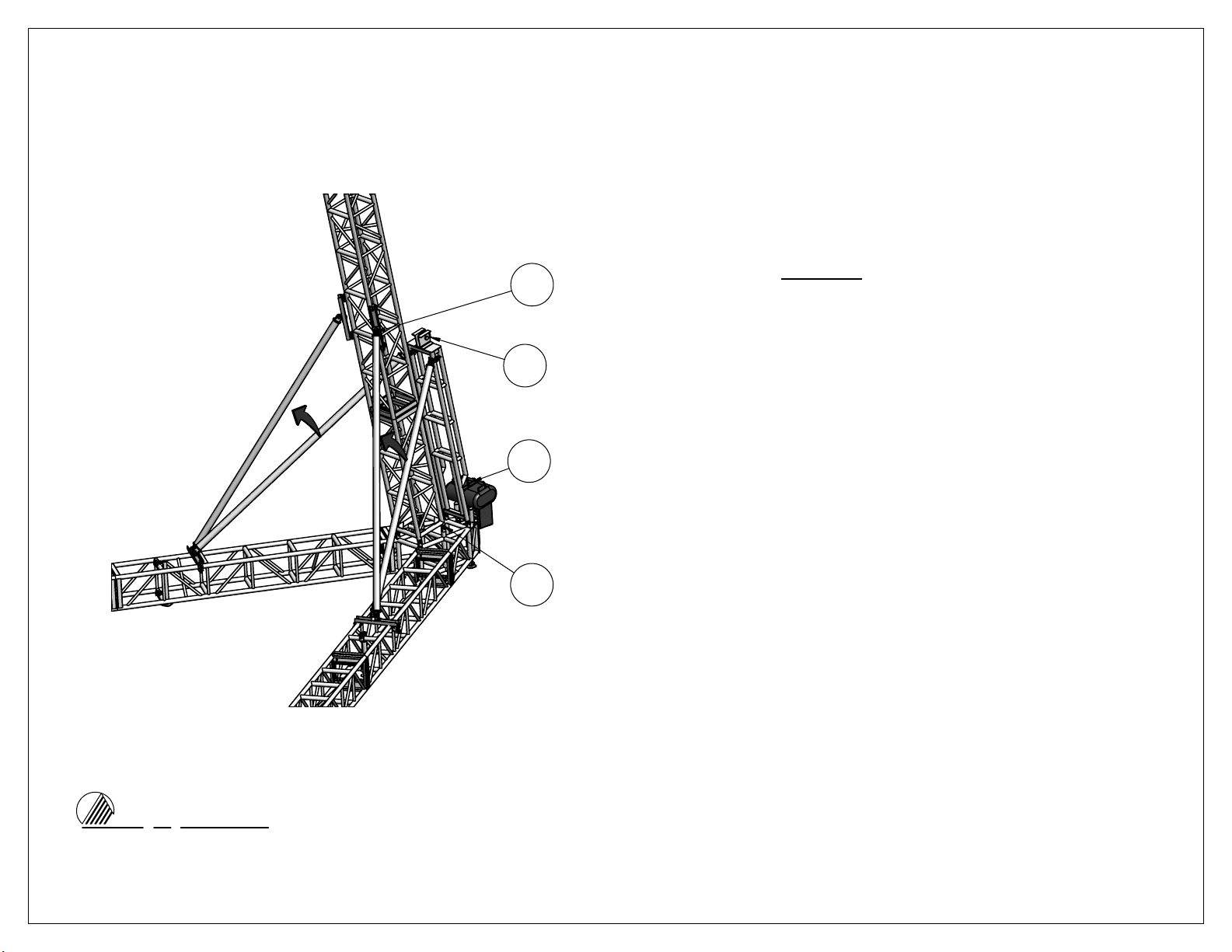

REQUIREMENTS FOR SAFE USE

1) Build Tower on flat surface.

2) Thick wood or metal plates under leveling jacks.

3) Don't lift tower with a load.

4)

SEE ENGINEERING REPORT FOR BALLAST REQUIREMENTS

THIS TOWER SHOULD BE ASSEMBLED/ERECTED AND

BALLASTED BY QUALIFIED RIGGERS.

***BALLAST IS NOT PROVIDED ***

BILL OF GOODS

QTY: (2) 16” LA1630 Towers

(2) V-BASES

(2) HINGE SECTIONS

(4) 10’ 16IN TOWER TRUSS (TOWERS)

(2) 5’ 16IN TOWER TRUSS (TOWERS)

(2) HEAD BLOCKS

(4) 10’ 16IN BOX TRUSS (LEGS)

(4) 8' 16IN BOX TRUSS (LEGS)

(4) LEG PLATES

(4) LEG BRACKETS

(4) TOWER BRACKETS

(4) MOTOR SUPPORTS

(2) LIFTING LADDERS

(4) TOWER BRACES

(96) 5/8-11 BOLT SETS

> WITH (192)WASHERS AND (96) NUTS

(24) 3/4 X 2-1/2” CLEVIS PINS WITH R-CLIPS

(4) LEVELING JACK TUBES

(20) LEVELING JACKS

(2) SETS OF BUILD INSTRUCTIONS

Shipped on 2 pallets

LA16-30 / LA16-35 TOWER

INSTRUCTIONS

ALWAYS...IF YOU HAVE QUESTIONS, PLEASE CALL!

(757)591-9371

PROUDLY MADE IN THE U.S.A.

722 Blue Crab Road

Newport News, VA 23606

757.591.9371 / fax 757.591.9514

www.appliednn.com

REVISED: 02Oct19