Lenni – Lucey Standard Table Manual

Table of Contents

APQS Customer Service & Suport ..............................................................................................5

APQS Certified Technicians ........................................................................................................5

Warranty Information ................................................................................................................5

Assembly Preparation Tips.........................................................................................................6

General Assembly Order ............................................................................................................8

Assembly Tools...........................................................................................................................9

Shipping Box Content...............................................................................................................10

Standard Table Step 1: Assemble the Rails & Legs.................................................................11

Standard Table - Step 2: Determine Table Orientation & Attach Legs to Rails.......................13

Standard Table - Step 3: Install the Table Top ........................................................................20

Standard Table - Step 4: Install the Roller End Arms...............................................................22

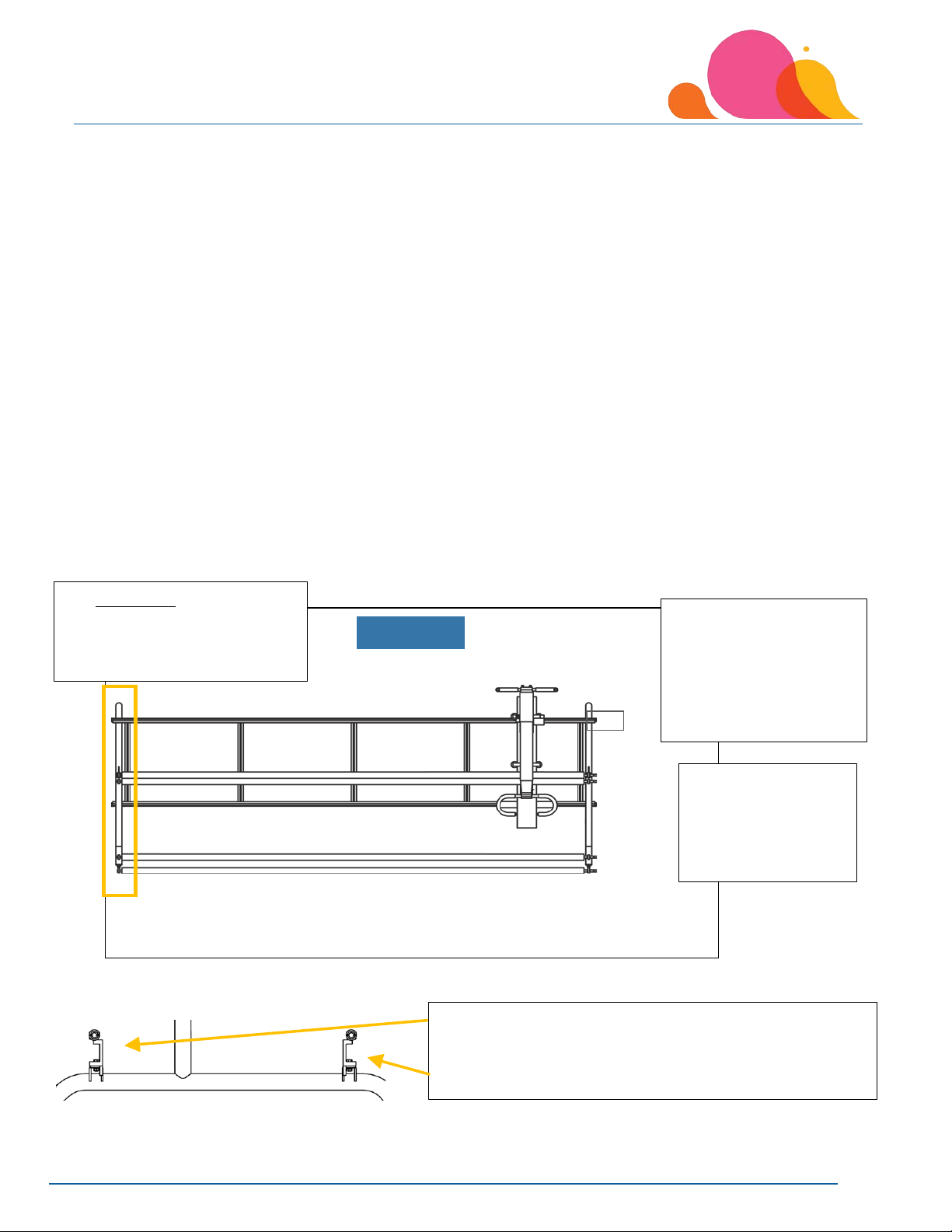

Step 5 (a): Install the Carriage (Bliss Track) .............................................................................25

Step 5 (b): Install the Carriage (NON-Bliss Track)....................................................................27

Step 6: Install the Sewing Head...............................................................................................31

Standard Table - Step 7: Install the Rollers .............................................................................34

Standard Table - Step 8: Install the Roller Hardware...............................................................37

Step 9: Install the Thread Stand & Laser Bolt...........................................................................40

Step 10: Install the Rear Handles .............................................................................................41

Step 11: Connect Cables and Power (Non-Quilt Path).............................................................43

Step 12: Machine Operation of Lenni & Lucey ........................................................................46

APQS Bobbin Winder Setup & Maintenance ...........................................................................53

Daily Machine Maintenance ....................................................................................................64

General Machine Maintenance................................................................................................69

Fuses ....................................................................................................................................69

Main Fuse Location and Replacement (ALL APQS Machines)..............................................69

Circuit Board Fuse ................................................................................................................72

Fuse Replacement (CSA Models) ........................................................................................76

Hopping Foot Height Verification........................................................................................80